In almost all intended applications, PTFE coating is perfectly safe. Its safety is fundamentally tied to temperature, and under normal operating conditions—whether on cookware or industrial parts—it remains stable and inert.

The safety of Polytetrafluoroethylene (PTFE) is not a question of the material itself, but of its environment. It is exceptionally stable and safe below its thermal decomposition point, but it can release hazardous fumes if significantly overheated.

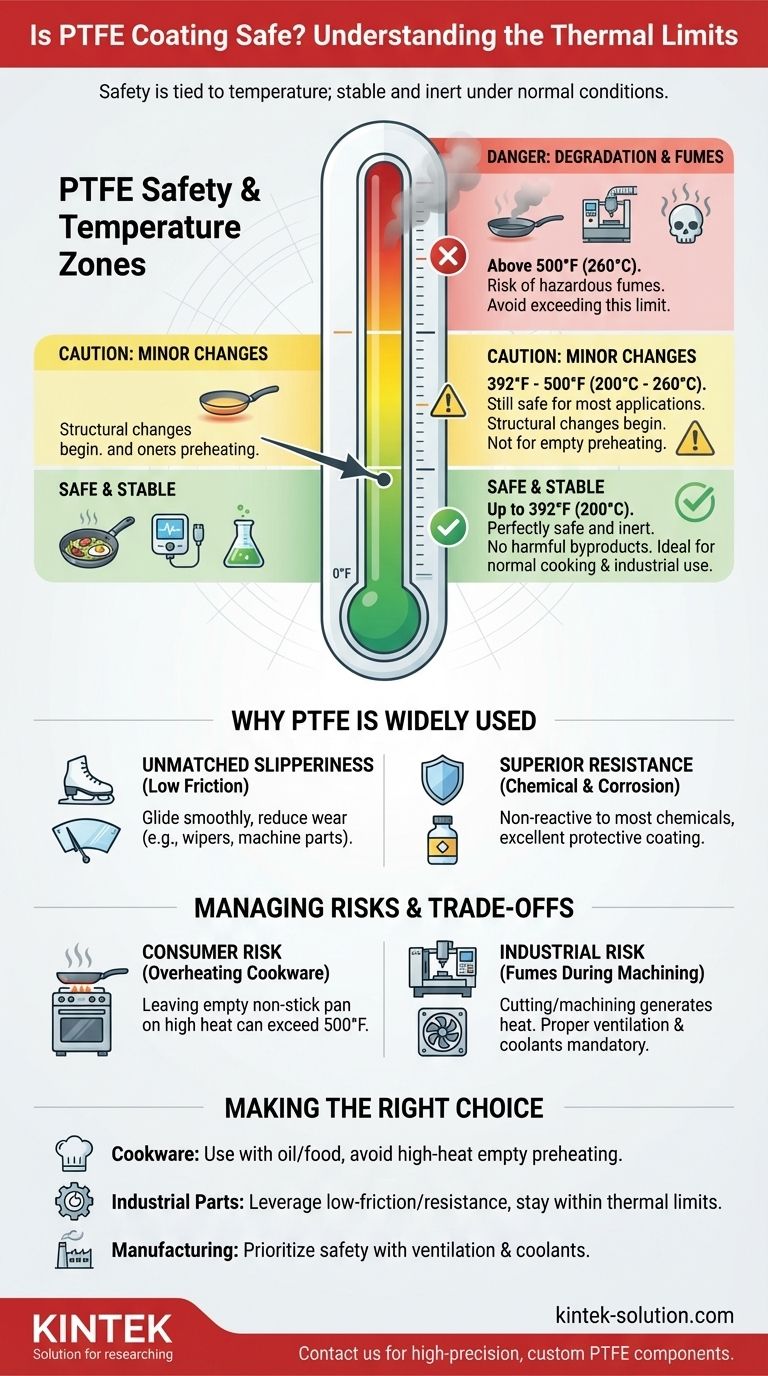

The Science of PTFE Safety: A Matter of Temperature

The entire discussion of PTFE safety hinges on understanding its behavior at different temperatures. It is not inherently toxic, but its chemical structure can break down under extreme heat.

The Stability Threshold: Up to 392°F (200°C)

At temperatures up to 392°F (200°C), PTFE is completely stable. It begins to show microscopic signs of structural change around this point, but studies confirm this does not produce harmful byproducts in any significant quantity.

The Degradation Point: Above 500°F (260°C)

The real safety threshold is 500°F (260°C). Above this temperature, PTFE begins to degrade and can release polymer fumes that are hazardous to inhale.

For context, this temperature is well above the smoke point of most cooking oils and the temperatures used for baking, searing, or frying. It is typically only reached when a pan is left empty on a high-heat burner for an extended period.

Why PTFE Is So Widely Used

PTFE's popularity stems from a unique combination of properties that make it invaluable in both consumer and industrial settings. Its safety profile under normal conditions allows these benefits to be leveraged widely.

Unmatched Slipperiness

PTFE is famous for being one of the most slippery materials known, giving it an extremely low coefficient of friction. This is why it's used on windshield wiper blades to help them glide smoothly and on machine parts to reduce wear.

Superior Resistance

This material is highly resistant to corrosion and does not react to most chemicals. This makes it an excellent protective coating for parts that are exposed to harsh operating conditions.

Understanding the Trade-offs and Risks

While safe in its intended use, there are specific contexts—primarily involving extreme heat or manufacturing processes—where risks must be managed.

The Consumer Risk: Overheating Cookware

For the average person, the only significant risk comes from severely overheating PTFE-coated cookware. Leaving an empty non-stick pan on a high burner can cause it to exceed 500°F, leading to the release of fumes.

The Industrial Risk: Fumes During Machining

During industrial manufacturing, cutting or machining PTFE can generate enough friction and heat to cause degradation. This process can create hazardous fumes, which is why proper ventilation and the use of coolants are mandatory in any facility that works with raw PTFE.

The Handling Challenge: A Practical Hurdle

An interesting operational challenge is that PTFE's extreme slipperiness can make coated parts difficult to hold or secure during assembly, requiring special measures.

Making the Right Choice for Your Application

Your approach to PTFE should be based entirely on your specific use case and an understanding of its thermal limits.

- If your primary focus is consumer cookware: Use your non-stick pans for cooking with oil or food and avoid preheating them empty on high heat to stay well below the 500°F degradation point.

- If your primary focus is industrial parts: Leverage PTFE for its exceptional low-friction and corrosion-resistant properties, but ensure your design's maximum operating temperature remains safely under its thermal limits.

- If your primary focus is manufacturing with PTFE: You must prioritize worker safety by implementing robust ventilation systems and using specialized tools and coolants to manage heat during machining.

Understanding and respecting its thermal limits is the key to leveraging PTFE's remarkable properties safely and effectively.

Summary Table:

| Temperature Range | PTFE Status | Safety & Notes |

|---|---|---|

| Up to 392°F (200°C) | Stable | Perfectly safe and inert; no harmful byproducts. |

| 392°F - 500°F (200°C - 260°C) | Minor Changes | Still safe for most applications; structural changes begin. |

| Above 500°F (260°C) | Degrades | Risk of hazardous fumes; avoid exceeding this limit. |

Need high-precision, custom PTFE components that are safe and reliable for your application?

At KINTEK, we specialize in manufacturing premium PTFE seals, liners, labware, and custom parts for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components are fabricated to the highest standards, operating safely within their thermal limits.

Let us help you leverage PTFE's superior properties with confidence. Contact our team today for a consultation on your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE and what is its commercial name? A Guide to Teflon and ePTFE

- What makes PTFE suitable for food manufacturing and packaging? Ensure Safety and Efficiency

- How does PTFE benefit fabric and carpet protection? Achieve Superior Stain and Soil Resistance

- How is PTFE used in the food and beverage industry? Ensuring Purity and Efficiency in Production

- How is PTFE applied in the electrical and electronics industries? Unlock High-Performance Insulation

- Are there any significant differences between PTFE and Teflon? The Truth About Brand vs. Material

- What makes Teflon a versatile coating material? Unlock Superior Performance in Your Application

- What makes PTFE suitable for chemical and pharmaceutical industries? Ensuring Purity and Performance in Critical Applications