In the construction industry, Teflon coating is not applied broadly like paint but is instead integrated into specific, high-performance components where its unique properties are essential. It serves primarily as a protective sheathing for wiring and a durable, low-friction surface for structural and mechanical parts.

The core function of Teflon in construction is not as a general-purpose coating, but as a specialized material engineered into key components to enhance safety, reduce maintenance, and ensure long-term durability against heat, chemicals, and electricity.

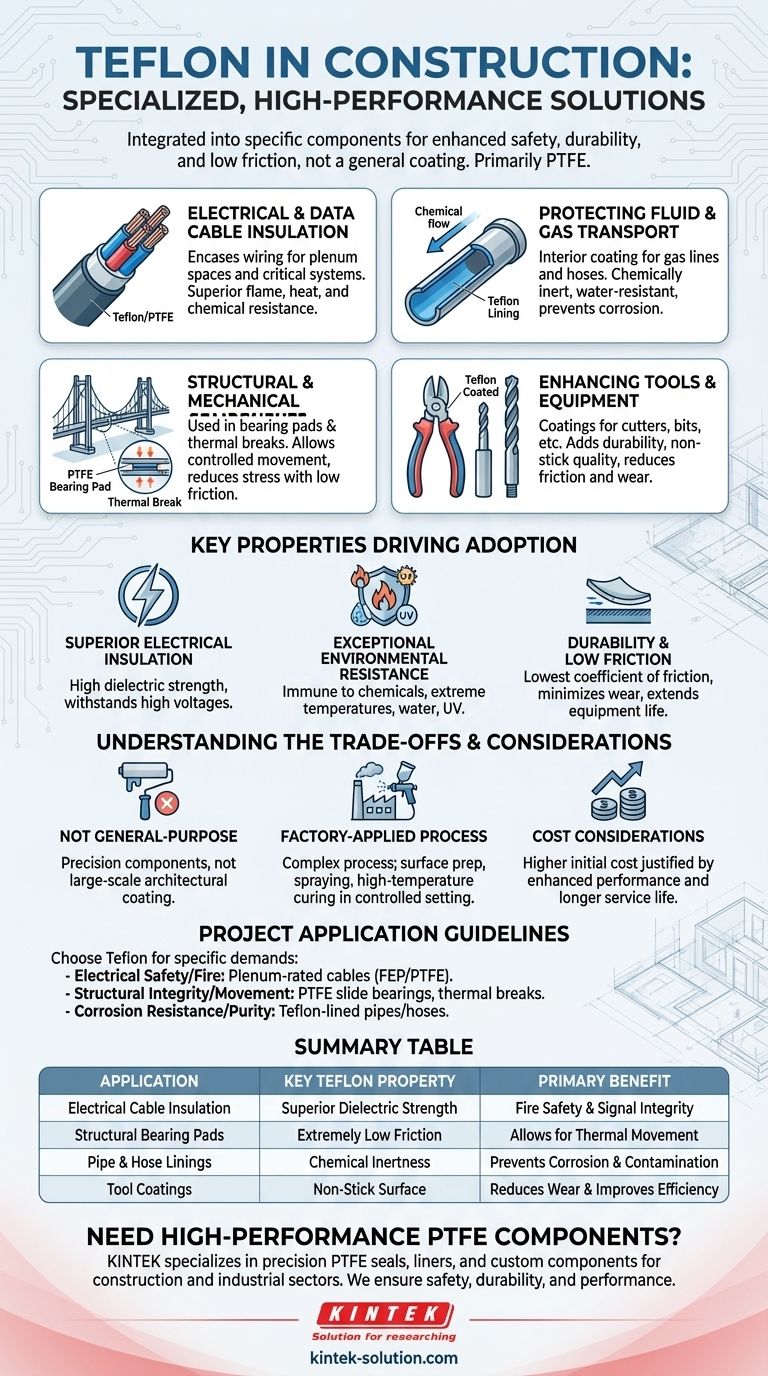

Core Applications of Teflon in Construction

Teflon, most commonly Polytetrafluoroethylene (PTFE), is specified for components that must withstand harsh operating conditions. Its use is targeted and strategic, focused on solving specific engineering challenges.

Electrical and Data Cable Insulation

The most critical use of Teflon in construction is for encasing and insulating electrical wiring.

Its properties make it ideal for plenum spaces and critical systems where fire safety and signal integrity are paramount. It offers superior resistance to flames, heat, and chemicals compared to standard insulators.

Protecting Fluid and Gas Transport

Teflon coatings are applied to the interior of gas line pipes and industrial hoses.

Because it is chemically inert and water-resistant, it prevents corrosion and ensures the purity of the substances being transported, contributing to the system's longevity and safety.

Structural and Mechanical Components

PTFE is used to manufacture structural bearing pads and thermal breaks.

These components are placed between structural elements, like steel beams and concrete supports, to allow for controlled movement from thermal expansion and contraction. The extremely low friction of Teflon prevents stress buildup in the structure.

Enhancing Tools and Equipment

Teflon is also used to coat professional tools like wire cutters, scissors, and drill bits.

This application adds durability and a non-stick quality, reducing friction and wear during use and making the tools last longer and perform more efficiently.

The Key Properties Driving Adoption

The selection of Teflon-based materials is driven by a combination of properties that are difficult to achieve with other polymers. Understanding these foundational benefits clarifies why it is chosen for such demanding roles.

Superior Electrical Insulation

Teflon has an exceptionally high dielectric strength, meaning it can withstand high voltages without breaking down. This makes it one of the most reliable insulators for wiring in sensitive and high-stakes environments.

Exceptional Environmental Resistance

This material is virtually immune to chemical attack and is highly resistant to extreme temperatures, water, and UV radiation. This ensures that components do not degrade when exposed to harsh construction site conditions or industrial environments.

Durability and Low Friction

Teflon possesses the lowest coefficient of friction of any known solid material. This "slipperiness" is essential for bearing pads and coated tools, minimizing wear and tear on moving parts and extending the operational life of the equipment.

Understanding the Trade-offs

While highly effective, Teflon is a specialized material, not a universal solution. Its application comes with important considerations that professionals must weigh.

Not a General-Purpose Coating

Teflon is not used as a large-scale architectural or protective coating for surfaces like walls or structural steel. Its value is in precision-engineered components, not broad application.

Factory-Applied Process

The application of industrial Teflon coatings is a complex, multi-stage process involving surface preparation, spraying, and high-temperature curing (sintering). This is performed in a controlled factory setting, not on a construction site.

Cost Considerations

As a high-performance polymer, components made with or coated in Teflon are typically more expensive than those using conventional materials. The cost is justified by enhanced safety, reduced maintenance needs, and a longer service life.

How to Apply This to Your Project

Your choice to specify Teflon-based components should be driven by the specific performance demands of your project.

- If your primary focus is electrical safety and fire resistance: Specify plenum-rated cables and wiring with FEP or PTFE insulation.

- If your primary focus is structural integrity and movement: Utilize PTFE slide bearings or thermal break pads in your structural designs.

- If your primary focus is corrosion resistance in piping: Consider Teflon-lined pipes and hoses for aggressive chemical or high-purity applications.

Ultimately, Teflon serves as a critical problem-solver in modern construction, engineered for the precise points where performance cannot be compromised.

Summary Table:

| Application | Key Teflon Property | Primary Benefit |

|---|---|---|

| Electrical Cable Insulation | Superior Dielectric Strength | Fire Safety & Signal Integrity |

| Structural Bearing Pads | Extremely Low Friction | Allows for Thermal Movement |

| Pipe & Hose Linings | Chemical Inertness | Prevents Corrosion & Contamination |

| Tool Coatings | Non-Stick Surface | Reduces Wear & Improves Efficiency |

Need high-performance PTFE components for your construction project? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components for the construction, industrial, and specialized sectors. We ensure your critical systems meet the highest standards for safety, durability, and performance.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications