In short, PTFE flat washers are considered ideal for industrial machinery because they solve multiple problems simultaneously where other materials would fail. Their unique combination of extreme chemical resistance, an incredibly low friction surface, and a wide operational temperature range provides a durable, maintenance-free solution for sealing, spacing, and insulating critical components in harsh environments.

The core reason PTFE washers are a default choice in demanding industrial applications is their "fit-and-forget" reliability. They thrive in environments with corrosive chemicals, extreme temperatures, and high friction, extending the life of machinery while reducing the need for lubrication and frequent maintenance.

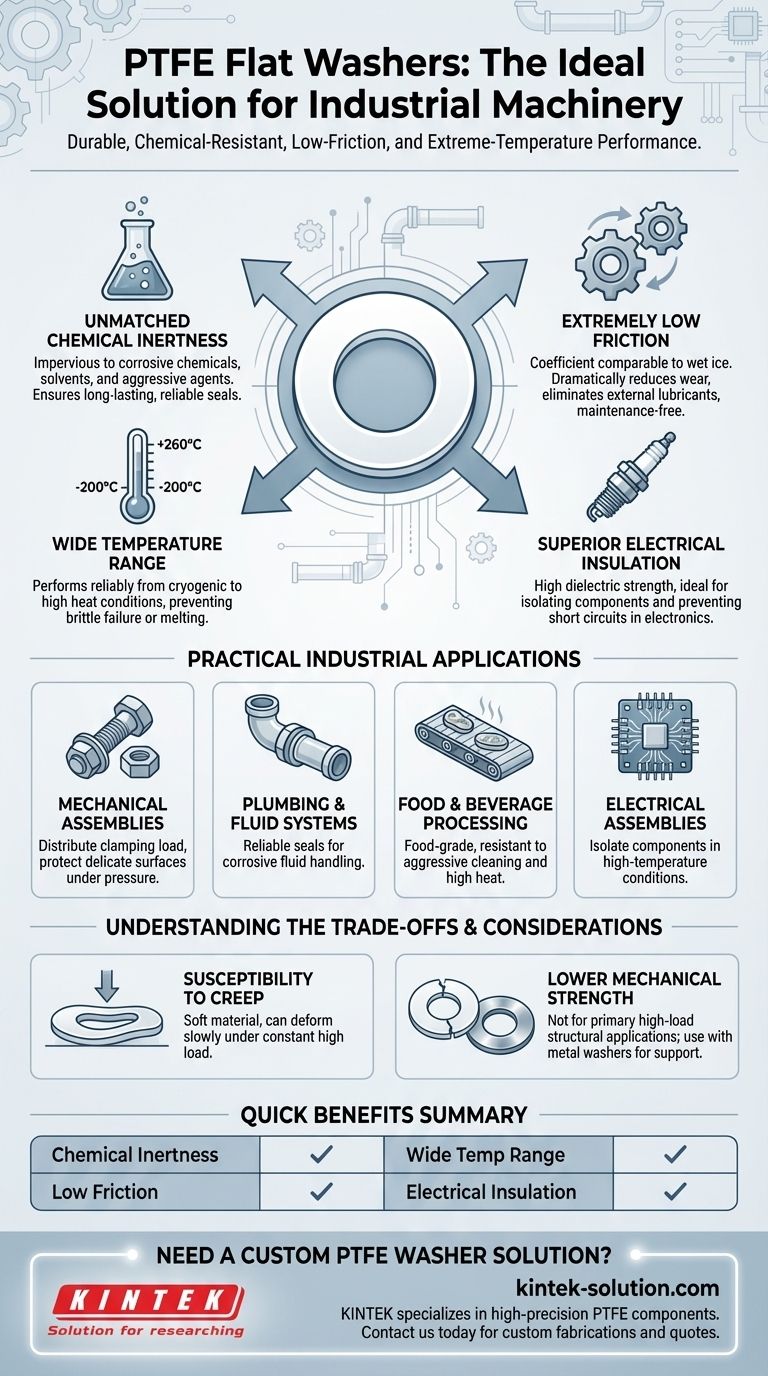

The Core Properties of PTFE in Industrial Settings

To understand why PTFE is so effective, we need to look at its fundamental material properties and how they translate directly to industrial benefits.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. This makes it impervious to nearly all industrial chemicals, solvents, and corrosive agents.

This property ensures that the washer will not degrade, swell, or fail when exposed to aggressive substances, guaranteeing a long-lasting and reliable seal or spacer.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a major advantage.

In applications with moving parts, like gears and bearings, PTFE washers reduce wear and tear dramatically. This anti-friction property often eliminates the need for external lubricants, creating a cleaner and more maintenance-free system.

Wide Operational Temperature Range

PTFE washers perform reliably across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes them suitable for machinery that operates in cryogenic applications or generates significant heat, without the material becoming brittle or melting.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, possessing high dielectric strength.

This makes it an ideal choice for electronics and electrical assemblies, where a washer must isolate components and prevent short circuits, especially in high-temperature conditions.

Practical Applications Across Industries

The unique properties of PTFE allow these washers to be used in a wide variety of demanding fields.

Mechanical Assemblies and Fastening

In general mechanical use, PTFE washers are placed under screw heads and nuts to distribute the clamping load over a wider area.

Their slight compressibility protects delicate surfaces from being damaged or stressed by the fastener, ensuring a secure connection without marring the component.

Plumbing and Fluid Systems

Due to their chemical inertness, PTFE washers are essential in industrial plumbing and fluid handling systems. They create reliable seals for bolts and fittings that are constantly exposed to corrosive fluids.

Food and Beverage Processing

PTFE is available in food-grade formulations, making it safe for contact with consumables.

Its resistance to aggressive cleaning chemicals and high temperatures makes it a perfect material for machinery in the food and beverage industry.

Understanding the Trade-offs

While exceptionally versatile, PTFE is not the solution for every single application. An objective evaluation requires acknowledging its limitations.

Susceptibility to Creep

PTFE is a relatively soft material. Under high, constant mechanical pressure (bolt torque), it can be susceptible to "creep" or "cold flow," meaning it can slowly deform over time. This can lead to a loss of bolt preload in high-stress structural joints.

Lower Mechanical Strength

Compared to metal washers, PTFE has significantly lower compressive and tensile strength. It is not designed for extremely high-load structural applications where the washer itself is a primary load-bearing element.

In such cases, a PTFE washer might be used in conjunction with a metal washer to provide a low-friction or corrosion-resistant surface while the metal washer provides the structural support.

Making the Right Choice for Your Application

Selecting the correct component depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical resistance: PTFE is almost certainly the best choice for sealing or spacing in corrosive environments.

- If your primary focus is reducing friction and wear: PTFE washers provide a self-lubricating surface that can significantly extend the life of moving components.

- If your primary focus is high-temperature or electrical insulation: PTFE's thermal stability and dielectric properties make it an excellent and reliable insulator.

- If your primary focus is extreme structural load-bearing: Consider a metal washer for strength, potentially using a PTFE washer alongside it for its surface properties.

Ultimately, PTFE flat washers offer a powerful and versatile solution for many of the most difficult challenges faced in modern industrial machinery.

Summary Table:

| Property | Benefit for Industrial Machinery |

|---|---|

| Chemical Inertness | Resists corrosive chemicals, ensuring long-lasting seals. |

| Low Friction | Reduces wear, eliminates lubrication needs. |

| Wide Temperature Range | Performs from -200°C to +260°C, ideal for extreme conditions. |

| Electrical Insulation | Prevents short circuits in high-temperature assemblies. |

Need a custom PTFE washer solution for your machinery?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get a washer that perfectly fits your application's demands for chemical resistance, temperature stability, and low friction.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the most suitable PTFE grades for CNC machined parts? Achieve Optimal Performance and Durability

- What is the purpose of PTFE guide strips? Achieve Smooth, Reliable Motion in Your Systems

- How do PTFE bushes reduce friction between moving parts? Achieve Maintenance-Free, Low-Friction Motion

- What are the limitations of virgin PTFE for rotary shaft seals? Overcome Weakness with Filled Compounds

- Why are quad rings preferred over O-rings in dynamic applications? Prevent Spiral Failure & Reduce Friction

- What are the advantages of compression molding for PTFE? Unlock Superior Performance for Large, Dense Components

- Why is PTFE preferred for electric actuated butterfly valves? For Unmatched Reliability in Harsh Conditions

- What are PTFE compounds and how are they used? Enhance Performance for Demanding Applications