While known for its exceptional chemical and thermal properties, virgin Polytetrafluoroethylene (PTFE) has significant mechanical limitations that restrict its use in rotary shaft seals. Its primary weaknesses are very limited wear resistance, low stiffness, and poor compressive strength. This makes unfilled PTFE suitable only for a narrow range of light-duty, slow-speed rotary applications where system pressures are extremely low.

The limitations of virgin PTFE are not an indictment of PTFE seals as a category. Instead, they highlight why specialized fillers are almost always added, transforming the material from a mechanically weak polymer into a robust, high-performance sealing solution for demanding applications.

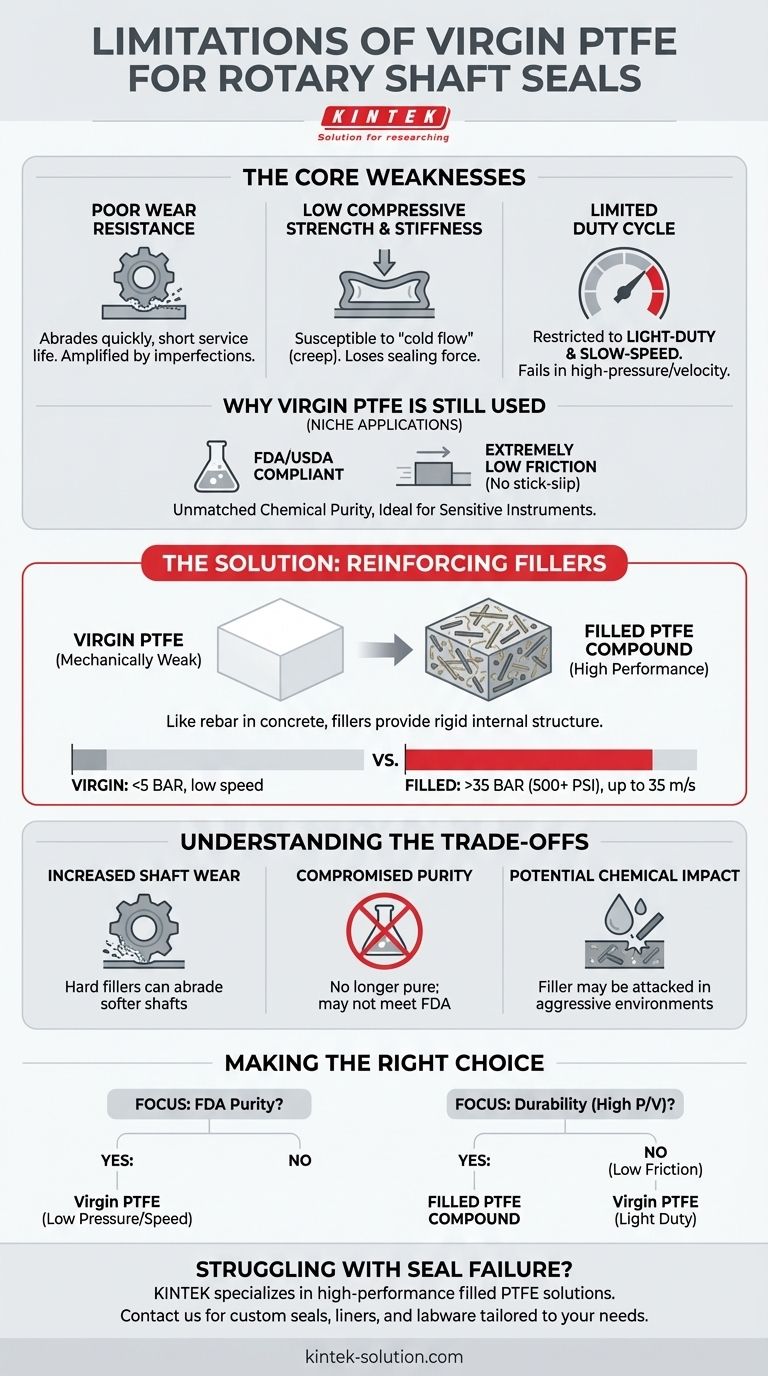

The Core Weaknesses of Unfilled (Virgin) PTFE

To understand why most high-performance PTFE seals are not made from virgin material, we must first examine its inherent physical shortfalls.

Poor Wear Resistance

Virgin PTFE is a relatively soft material. When used as a dynamic seal against harder shaft surfaces, it abrades quickly, leading to a short service life.

This issue is amplified in applications with even minor surface imperfections on the shaft or the presence of abrasive media.

Low Compressive Strength and Stiffness

Unfilled PTFE is susceptible to "cold flow," or creep, where the material permanently deforms over time when subjected to a constant load.

This lack of stiffness and compressive strength means it cannot maintain its sealing force and geometry under significant pressure, leading to seal failure.

Limited Duty Cycle

The combination of poor wear resistance and low strength restricts virgin PTFE seals to light-duty and slow-speed rotary applications.

Attempting to use it in high-pressure or high-velocity conditions will result in rapid failure, making it an impractical choice for most industrial machinery.

Why Virgin PTFE Is Still Used

Despite its mechanical weaknesses, virgin PTFE has specific characteristics that make it the ideal choice for a select few, highly specialized applications.

Unmatched Chemical Purity

Virgin PTFE is one of the most chemically inert polymers available and can be FDA and USDA compliant.

This makes it essential for applications in food processing, pharmaceuticals, and medical devices where contamination from seal fillers is not permissible.

Extremely Low Coefficient of Friction

Unfilled PTFE has an exceptionally low coefficient of friction, resulting in very low breakout friction and no stick-slip behavior.

This is critical in sensitive instruments or systems where seal-generated torque must be absolutely minimized.

Overcoming the Limitations: The Role of Fillers

The solution to the mechanical weaknesses of virgin PTFE is the addition of reinforcing fillers. This creates a PTFE "compound" that retains the best qualities of the base polymer while dramatically improving its physical strength.

How Fillers Transform PTFE

Think of fillers as the rebar in concrete. They provide a rigid internal structure that helps the PTFE matrix resist wear, deformation, and extrusion under load.

This enhancement allows PTFE seals to operate at pressures exceeding 35 BAR (500+ PSI) and surface speeds up to 35 m/s, far beyond the capabilities of the virgin material.

A Foundation for High Performance

By adding fillers, engineers can leverage PTFE's outstanding chemical resistance, self-lubricating nature, and wide temperature tolerance (from -64°F to 450°F / -53°C to 232°C) in demanding dynamic applications where virgin material would fail instantly.

Understanding the Trade-offs

Adding fillers is not without compromise. Selecting the right compound involves balancing the need for mechanical strength against other performance factors.

Fillers Can Increase Shaft Wear

While fillers make the seal more durable, some harder fillers (like glass fiber) can be more abrasive to the mating shaft surface, especially if the shaft material is not sufficiently hardened.

Compromised Chemical Purity

The addition of any filler means the material is no longer pure PTFE. This can be a critical issue in sanitary applications, as the seal may no longer meet FDA standards.

Potential Impact on Chemical Resistance

While the PTFE base remains highly resistant, the filler material itself may not be. In aggressive chemical environments, the filler could be attacked, compromising the seal's integrity.

Making the Right Choice for Your Application

Your application's specific demands will determine whether virgin PTFE is viable or if a filled compound is necessary.

- If your primary focus is FDA compliance or absolute chemical purity: Virgin PTFE is the correct choice, but you must design the system to operate within its strict low-pressure and low-speed mechanical limits.

- If your primary focus is durability in a high-speed or high-pressure environment: A filled PTFE compound is required. Virgin PTFE is fundamentally unsuitable for this role.

- If your primary focus is minimizing friction in a sensitive, light-duty system: Virgin PTFE is a strong candidate, offering the lowest possible friction and preventing stick-slip motion.

Ultimately, understanding the specific limitations of virgin PTFE is the key to selecting a filled compound that delivers the high performance your application demands.

Summary Table:

| Limitation | Consequence | Solution |

|---|---|---|

| Poor Wear Resistance | Rapid abrasion, short seal life | Add reinforcing fillers (e.g., glass, carbon) |

| Low Compressive Strength | Cold flow, loss of sealing force under pressure | Use filled PTFE for higher pressure tolerance |

| Limited Duty Cycle | Restricted to light-duty, low-speed applications | Filled compounds enable high-speed, high-pressure use |

Struggling with PTFE seal failure? KINTEK specializes in manufacturing high-performance PTFE components, including custom seals, liners, and labware. We help semiconductor, medical, laboratory, and industrial clients overcome the limitations of virgin PTFE by providing durable, filled PTFE compounds tailored to your specific pressure, speed, and chemical requirements. From prototypes to high-volume orders, our precision production ensures reliability. Contact KINTEK today to discuss your application and get a solution that lasts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications