For CNC machined parts, the two most common grades of PTFE are Virgin and Glass-filled. Virgin PTFE is pure polytetrafluoroethylene, offering superior chemical resistance and electrical insulation ideal for medical, electrical, and food-grade applications. Glass-filled PTFE is a composite material that enhances the polymer's rigidity and wear resistance, making it the superior choice for mechanical components that must withstand physical stress.

The decision is not about finding the "best" PTFE, but rather the correct one for your specific goal. Virgin PTFE excels in purity and inertness, while filled grades are engineered materials designed to overcome PTFE's natural softness and enhance its mechanical properties for demanding applications.

Understanding the Foundation: Virgin PTFE

Virgin grade is the purest form of PTFE. It is synthesized directly from the monomer without any fillers or recycled material, giving it a distinct set of properties.

Unmatched Chemical Resistance and Purity

Because it contains no additives, virgin PTFE offers the highest level of chemical inertness. This makes it the default choice for components used in medical devices, food and beverage processing, and aggressive chemical environments.

Superior Electrical Insulation

Virgin PTFE possesses exceptional dielectric strength, meaning it can withstand high voltages without breaking down. This property makes it a top-tier material for high-performance electrical insulators, connectors, and wiring components.

Lowest Coefficient of Friction

The material is inherently slippery, giving it one of the lowest coefficients of friction of any solid. This is ideal for non-load-bearing applications like slide plates, chemical-resistant gaskets, and low-friction seals where minimal force is required.

Enhancing Performance: Filled PTFE Grades

While virgin PTFE is an excellent material, it is also very soft and prone to deforming under load (a phenomenon known as "creep"). Fillers are added to create composite grades that significantly improve its mechanical characteristics.

The Standard Upgrade: Glass-Filled PTFE

This is the most common filled grade. Adding glass fibers (typically 15% or 25%) drastically increases rigidity, compressive strength, and wear resistance. It's a cost-effective choice for bearings, seals, and structural parts that require better mechanical stability than virgin PTFE can offer.

For Improved Lubricity: Graphite-Filled PTFE

Adding graphite as a filler creates a self-lubricating composite. This grade is often chosen for dynamic applications like seals and bearings that operate in dry or high-speed conditions, as it further reduces the coefficient of friction and improves wear life.

For Maximum Wear Resistance: Carbon-Filled PTFE

Carbon fiber reinforcement provides excellent compressive strength and hardness, leading to superior wear resistance, especially in water and steam applications. It also improves thermal conductivity, helping to dissipate heat in high-speed bearings.

For High Loads: Bronze-Filled PTFE

Bronze fillers offer the highest compressive strength and thermal conductivity of all common PTFE grades. This makes bronze-filled PTFE the ideal choice for high-load bearing applications and hydraulic systems where it can withstand significant pressure without deforming.

Understanding the Trade-offs

Choosing a PTFE grade involves balancing competing properties. Optimizing for one characteristic often means compromising on another.

Virgin PTFE's Mechanical Limitations

The primary drawback of virgin PTFE is its poor mechanical performance. It is soft, has low wear resistance, and is highly susceptible to creep or cold flow, where the material slowly deforms under sustained pressure.

The Compromise of Filled Grades

Adding fillers almost always reduces certain base properties of PTFE. For example, glass, carbon, and bronze fillers can slightly diminish the material's chemical resistance and will significantly decrease its electrical insulating capabilities.

Abrasiveness and Tool Wear

Hard fillers like glass and bronze are abrasive. Machining these filled grades causes more rapid tool wear compared to machining virgin PTFE, which can increase manufacturing costs and require specialized tooling.

Critical Machining and Design Considerations

Successfully machining any grade of PTFE requires an understanding of its unique behavior.

The Challenge of Tight Tolerances

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Heat generated during CNC machining can easily cause the part to go out of tolerance (±0.02 mm or less) if not properly managed.

Achieving Precision

To achieve accuracy, use extremely sharp tools (HSS or carbide), optimized cutting speeds (300–500 m/min), and controlled feed rates (0.1–0.25 mm/rev). A liquid coolant is essential to dissipate heat and prevent material deformation.

The Importance of Annealing

For high-precision components, a stress-relieving (annealing) process is often necessary. This involves heating the material to a specific temperature and cooling it slowly to relax internal stresses, ensuring the final part remains dimensionally stable.

Proper Fixturing is Non-Negotiable

Because of its softness, PTFE can easily be crushed or distorted by excessive clamping pressure in a CNC machine. Fixtures must be designed to hold the workpiece securely but gently, providing broad support to prevent deformation.

Making the Right Choice for Your Application

To select the most suitable grade, align your primary requirement with the material's core strength.

- If your primary focus is biocompatibility, food safety, or extreme chemical purity: Virgin PTFE is the only reliable choice.

- If your primary focus is increased wear resistance and rigidity for structural parts: Glass-filled PTFE is the most common and effective starting point.

- If your primary focus is a self-lubricating bearing or dynamic seal: Consider a grade filled with graphite or a combination of glass and molybdenum disulfide.

- If your primary focus is maximum compressive strength for high-load applications: Bronze-filled or carbon-filled PTFE will provide the best performance.

Choosing the right PTFE grade from the outset is the most critical step toward manufacturing a successful and reliable machined component.

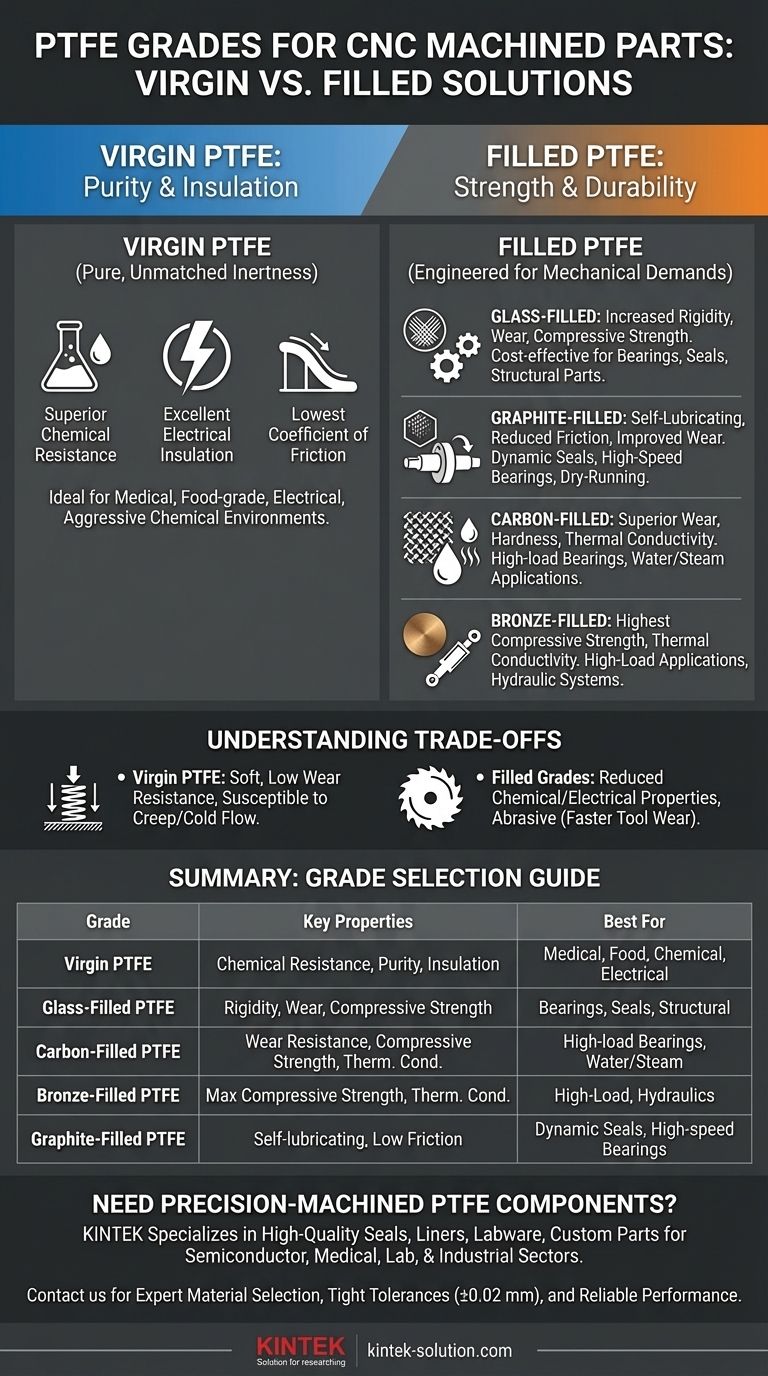

Summary Table:

| Grade | Key Properties | Best For |

|---|---|---|

| Virgin PTFE | Superior chemical resistance, electrical insulation, purity | Medical, food-grade, chemical processing, electrical components |

| Glass-Filled PTFE | Increased rigidity, wear resistance, compressive strength | Bearings, seals, structural parts requiring mechanical stability |

| Carbon-Filled PTFE | Excellent wear resistance, high compressive strength, thermal conductivity | High-load bearings, components in water/steam environments |

| Bronze-Filled PTFE | Maximum compressive strength, high thermal conductivity | High-load bearing applications, hydraulic systems |

| Graphite-Filled PTFE | Self-lubricating, low friction, improved wear life | Dynamic seals, high-speed bearings, dry-running applications |

Need precision-machined PTFE components for your industry?

KINTEK specializes in manufacturing high-quality PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We help you select the optimal PTFE grade and deliver precision CNC machining from prototypes to high-volume production.

Let us bring your project to life with:

- Expert material selection guidance

- Tight tolerance machining (±0.02 mm or less)

- Custom fabrication tailored to your application

- Reliable performance in demanding environments

Contact us today to discuss your PTFE machining needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts