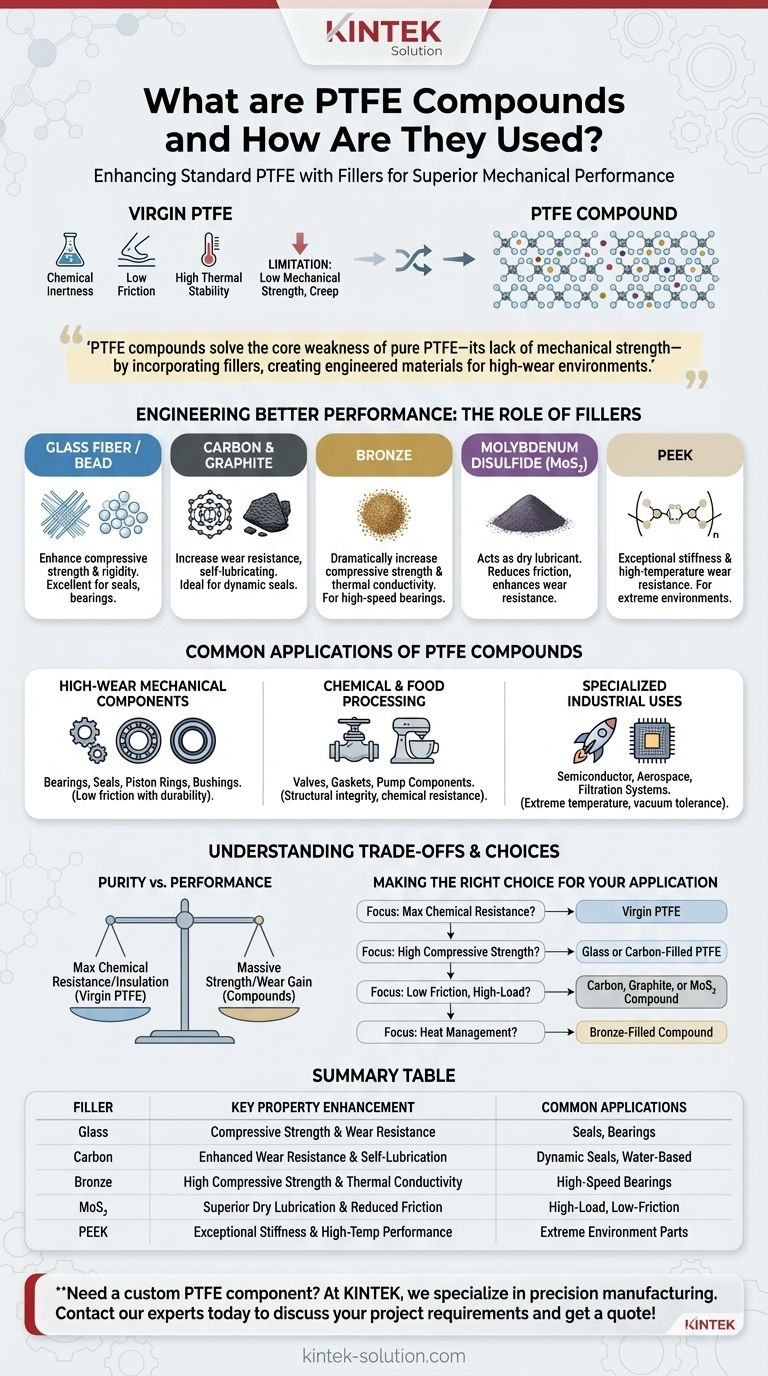

In essence, PTFE compounds are high-performance versions of standard PTFE (Polytetrafluoroethylene) that have been blended with filler materials to enhance specific mechanical properties. While pure PTFE is known for its incredible chemical resistance and low friction, it can be mechanically soft. Adding fillers like glass, carbon, or bronze creates a composite material with significantly improved strength, durability, and wear resistance for demanding industrial applications.

PTFE compounds solve the core weakness of pure PTFE—its lack of mechanical strength—by incorporating fillers. This creates a range of engineered materials tailored for high-wear and high-load environments where the properties of standard PTFE would be insufficient.

The Foundation: Understanding Pure PTFE

The Unique Properties of Virgin PTFE

Pure, or "virgin," PTFE is a remarkable polymer. Its primary characteristics are a nearly universal chemical inertness, an extremely low coefficient of friction (making it non-stick), and high thermal stability.

These properties make it an ideal choice for applications where purity, electrical insulation, or resistance to corrosive chemicals is the top priority.

The Inherent Limitation

The main drawback of virgin PTFE is its poor mechanical strength. It is susceptible to "creep" or deformation under a sustained load and has relatively low resistance to abrasion and wear. This makes it unsuitable for many structural or high-load mechanical parts.

Engineering Better Performance: The Role of Fillers

To overcome the mechanical limitations of pure PTFE, various filler materials are blended with the base PTFE resin. This process creates a "PTFE compound," where the final material gains the benefits of the filler.

Glass Fiber and Glass Bead Fillers

Adding glass, either in fiber or bead form, is a common way to enhance compressive strength and rigidity. Glass-filled PTFE exhibits excellent wear resistance, making it a staple for seals and bearings.

Carbon and Graphite Fillers

Carbon is added to significantly increase compressive strength, hardness, and wear resistance, especially in water-based applications.

Graphite is often added alongside carbon to lower the coefficient of friction and improve wear characteristics, creating a self-lubricating material ideal for dynamic seals.

Bronze Filler

Adding bronze powder dramatically increases compressive strength and thermal conductivity. This allows heat to dissipate more effectively from bearing surfaces, improving performance in high-speed applications.

Molybdenum Disulfide (MoS₂) Filler

Often used in smaller quantities with other fillers, Molybdenum Disulfide (MoS₂) acts as a dry lubricant. It further reduces friction and enhances the wear resistance of the compound.

PEEK Filler

For the most demanding environments, PEEK (Polyetheretherketone) can be used as a filler. This combines PTFE's low friction with PEEK's exceptional stiffness and wear resistance at high temperatures.

Common Applications of PTFE Compounds

The enhanced properties of PTFE compounds open up a wide range of uses in harsh industrial settings where pure PTFE would fail.

High-Wear Mechanical Components

This is the largest area of use. Compounds filled with glass, carbon, and bronze are used to manufacture bearings, seals, piston rings, and bushings. They provide the low friction of PTFE with the durability needed to withstand mechanical stress.

Chemical and Food Processing

While maintaining most of PTFE's chemical resistance, compounds offer the structural integrity needed for valves, gaskets, and pump components used in chemical handling. They are also used for durable parts in food processing equipment.

Specialized Industrial Uses

PTFE compounds are critical in applications requiring tolerance to extreme temperatures, high impact, or vacuums. This includes components for semiconductor manufacturing, aerospace parts, and specialized filtration systems.

Understanding the Trade-offs

Choosing a PTFE compound is an engineering decision that involves balancing competing properties. It is not a one-size-fits-all solution.

Purity vs. Performance

The primary trade-off is purity versus mechanical performance. Adding any filler will slightly diminish the absolute chemical resistance and electrical insulating properties of virgin PTFE. The benefit, however, is a massive gain in strength and wear life.

The Right Filler for the Job

The choice of filler is deliberate. A bronze-filled compound is excellent for thermal conductivity but would be unsuitable for highly corrosive chemical service. A carbon-filled compound excels in wear resistance but might not be the best choice for an electrical insulator.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary goal.

- If your primary focus is maximum chemical resistance and electrical insulation: Virgin PTFE is the only choice.

- If your primary focus is high compressive strength and general wear resistance: A glass-filled or carbon-filled PTFE compound is a robust and common solution.

- If your primary focus is low friction in high-load, dynamic applications: A compound with graphite, carbon, or Molybdenum Disulfide will provide self-lubricating properties.

- If your primary focus is managing heat in high-speed applications: A bronze-filled compound offers the necessary thermal conductivity.

By understanding the role of fillers, you can select the precise PTFE compound engineered to meet your specific performance requirements.

Summary Table:

| Filler Material | Key Property Enhancement | Common Applications |

|---|---|---|

| Glass Fiber/Bead | Increased compressive strength & wear resistance | Seals, bearings, bushings |

| Carbon/Graphite | Enhanced wear resistance & self-lubrication | Dynamic seals, water-based applications |

| Bronze | High compressive strength & thermal conductivity | High-speed bearings, heat dissipation parts |

| Molybdenum Disulfide (MoS₂) | Superior dry lubrication & reduced friction | High-load, low-friction components |

| PEEK | Exceptional stiffness & high-temperature performance | Extreme environment parts, aerospace components |

Need a custom PTFE component that balances chemical resistance with mechanical strength? At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and other critical components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise in custom fabrication ensures you get the right material solution for your specific application. Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What applications are suitable for spring energized PTFE seals? Master Extreme Sealing Challenges

- How does PTFE's friction coefficient benefit dynamic sealing applications? Enhance Efficiency and Longevity

- What general maintenance practices can extend the lifespan of PTFE gaskets? Optimize Selection, Installation, and Monitoring

- In which industries are PTFE-lined piping systems commonly used? Ensure Safety and Purity in Harsh Environments

- What are the key properties of PTFE guide strips? Ensure Low-Friction, High-Temp Performance

- What is the significance of low surface adhesion in PTFE diaphragm valves for pharmaceutical research? Ensure Sample Integrity and Process Reliability

- What are some examples of ePTFE applications in aerospace and automotive industries? Critical Components for Extreme Environments

- What design parameters are specified for PTFE sliding bearings? Ensure Structural Safety and Performance