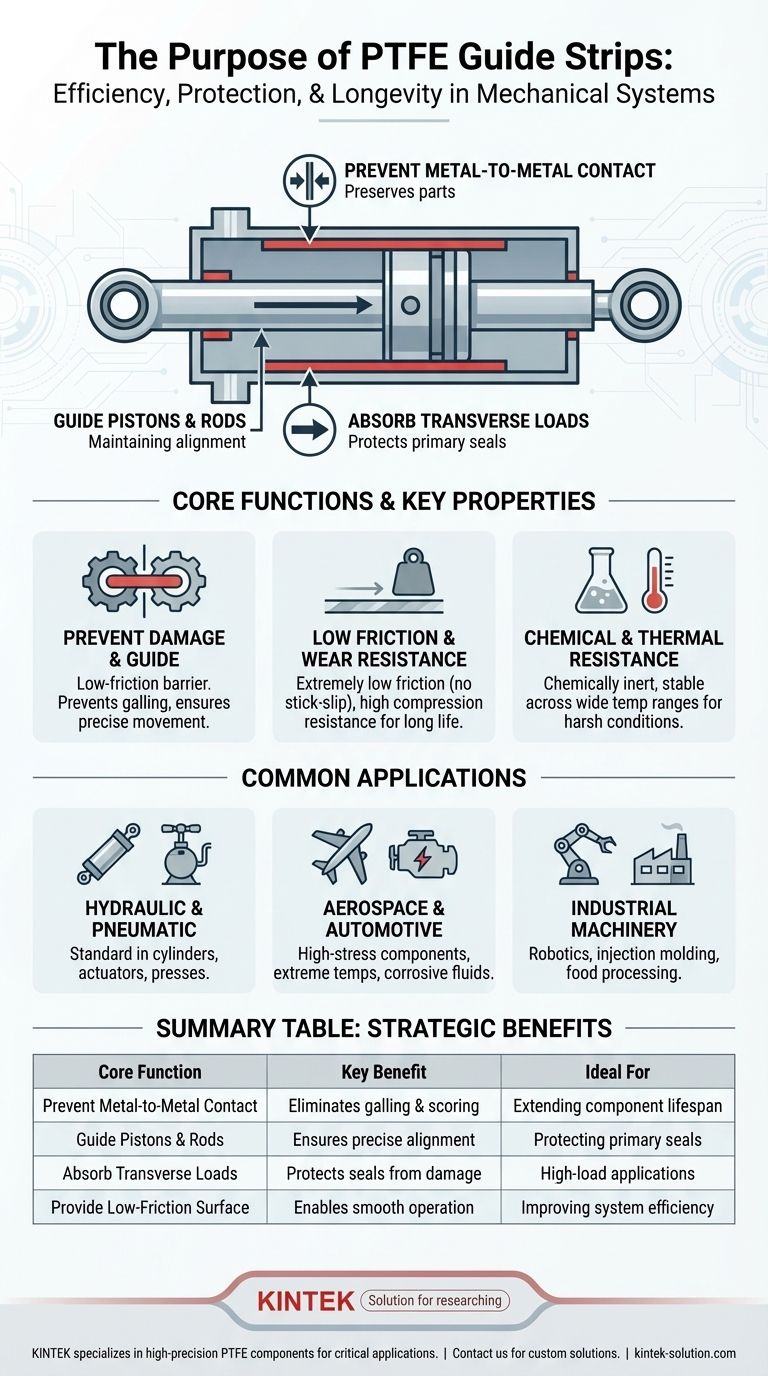

At their core, PTFE guide strips serve a critical dual purpose: they prevent damaging metal-to-metal contact between moving parts and precisely guide components like pistons and rods within a system. This action is fundamental to reducing friction, preventing wear, and ensuring smooth, reliable operation in demanding applications.

The essential purpose of a PTFE guide strip is to function as a sacrificial bearing element. It absorbs destructive side-loads and minimizes friction to protect more critical components, thereby enhancing the efficiency and dramatically extending the service life of the entire assembly.

The Core Functions of PTFE Guide Strips

PTFE guide strips are not merely passive spacers; they are active engineering components that perform several vital roles simultaneously.

Preventing Damaging Metal-to-Metal Contact

The most fundamental purpose is to create a low-friction barrier between metallic components, such as a piston and a cylinder bore. This barrier prevents the galling, scoring, and general deterioration that occurs when metals rub against each other under load.

By preventing this direct contact, the strips preserve the integrity and surface finish of critical, expensive parts.

Guiding Pistons and Rods

In hydraulic and pneumatic systems, maintaining the precise alignment of the piston and rod is paramount for performance. Guide strips ensure these components travel along their intended axis without tilting.

This guidance is crucial for the proper function of the system's primary seals, which are not designed to handle significant side forces.

Absorbing Transverse Loads

Guide strips are specifically engineered to absorb and manage transverse (or radial) loads. These are side forces that push the rod or piston against the cylinder wall.

By bearing these loads, the guide strips protect the main rod or piston seal from being deformed or damaged, which would otherwise lead to system failure.

The Key Properties That Make PTFE Ideal

The choice of PTFE (Polytetrafluoroethylene) is deliberate, owing to a unique combination of material properties that make it exceptionally suited for this role.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is critical for ensuring smooth, stick-slip-free operation, where the component moves without stuttering or jerking.

This low friction also minimizes energy loss within the system and ensures that lubrication is more effective.

High Wear and Compression Resistance

Despite its smooth surface, PTFE is highly resistant to wear and can withstand significant compressive forces. This allows it to handle high load capacities without being quickly destroyed.

This durability translates directly to a long service life, reducing the need for frequent maintenance and replacement.

Excellent Chemical and Thermal Resistance

PTFE is chemically inert, meaning it is unaffected by almost all industrial chemicals, fluids, and corrosive agents. It also exhibits excellent thermal stability across a wide range of temperatures.

These characteristics make it a reliable choice for harsh operating conditions found in aerospace, automotive, and chemical processing industries.

Common Applications Across Industries

The unique benefits of PTFE guide strips have led to their widespread adoption in numerous sectors where reliability and performance are critical.

Hydraulic and Pneumatic Systems

This is the primary application area. Guide strips are standard components in hydraulic cylinders, shock absorbers, presses, and pneumatic actuators, where they are essential for protecting seals and ensuring smooth motion.

Aerospace and Automotive

In aerospace, they are used in high-stress components like landing gear and control surfaces that are exposed to extreme temperatures. In the automotive sector, they are found in engine components and braking systems to minimize wear and resist corrosive fluids.

General Industrial Machinery

Their use extends to robotics, injection molding presses, agricultural equipment, and food and beverage processing machinery. In each case, they serve to improve efficiency and extend the operational life of moving parts.

Making the Right Choice for Your Goal

Understanding the primary benefit of PTFE guide strips allows you to apply them effectively to solve specific engineering challenges.

- If your primary focus is extending component lifespan: Use PTFE guide strips to prevent metal-to-metal contact and absorb damaging radial loads that cause premature wear.

- If your primary focus is improving system efficiency: Leverage the material's extremely low coefficient of friction to eliminate stick-slip effects and reduce energy loss.

- If your primary focus is reliability in harsh environments: Rely on PTFE's superior chemical and thermal resistance to ensure consistent performance under extreme conditions.

Ultimately, incorporating PTFE guide strips is a strategic decision to build more robust, efficient, and long-lasting mechanical systems.

Summary Table:

| Core Function | Key Benefit | Ideal For |

|---|---|---|

| Prevent Metal-to-Metal Contact | Eliminates galling and scoring | Extending component lifespan |

| Guide Pistons & Rods | Ensures precise alignment | Protecting primary seals |

| Absorb Transverse Loads | Protects seals from damage | High-load applications |

| Provide Low-Friction Surface | Enables smooth, stick-slip-free operation | Improving system efficiency |

Need reliable PTFE components for your critical applications?

KINTEK specializes in manufacturing high-precision PTFE guide strips, seals, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems achieve maximum efficiency, longevity, and performance, even in the most demanding environments.

Contact us today for a custom solution to enhance your mechanical assemblies.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications