In demanding industrial settings, PTFE is the preferred material for electric actuated butterfly valve seats and linings because its unique combination of properties directly addresses the challenges of automated flow control. Its superior chemical inertness, high-temperature stability, and low-friction surface ensure unparalleled reliability and safety when handling aggressive or high-purity media.

The core reason for choosing PTFE is not just its individual strengths, but how they synergize with an electric actuator. This combination creates a highly reliable, low-maintenance, and precise automated valve system capable of performing in environments where other materials would quickly fail.

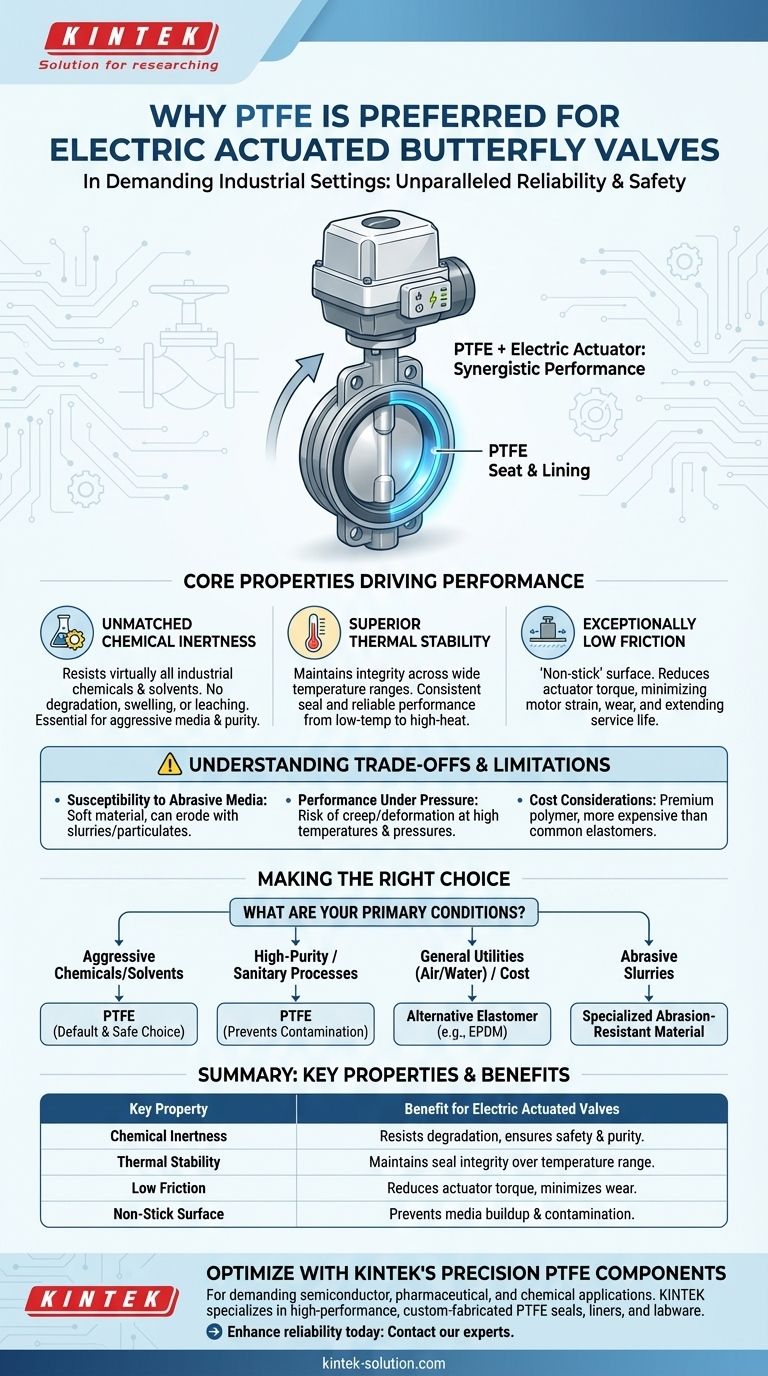

Why Material Choice is Critical in Automated Valves

The pairing of a valve with an electric actuator is a commitment to precision, repeatability, and automation. The valve's internal components, particularly the seat that contacts the media, must support these goals without compromise.

The Demands of Electric Actuation

An electric actuator provides precise, consistent torque to open and close the valve. A valve material that swells, degrades, or creates high friction forces the actuator to work harder, leading to motor burnout and operational failure.

The High Stakes of Industrial Fluids

Many industrial processes involve fluids that are highly corrosive, extremely hot, or must remain perfectly pure. A failure in the valve material can lead to dangerous leaks, product contamination, and costly downtime.

The Core Properties of PTFE That Drive Performance

Polytetrafluoroethylene (PTFE) offers a trifecta of properties that makes it exceptionally well-suited for these automated, high-consequence applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This means it will not degrade, swell, or leach contaminants into the process media, a critical requirement in chemical, pharmaceutical, and semiconductor manufacturing.

Superior Thermal Stability

PTFE maintains its integrity across a very wide temperature range. This stability ensures the valve provides a consistent seal and reliable performance whether the application involves low-temperature fluids or high-temperature processing.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality ensures the valve disc can rotate smoothly with minimal torque from the electric actuator, reducing wear and extending the valve's service life.

Contamination Prevention

The same non-stick surface that lowers friction also prevents media from accumulating on the valve components. This is essential in industries like pharmaceuticals or food processing, where material buildup can lead to contamination and violate stringent safety regulations.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. An objective assessment requires acknowledging its operational boundaries.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. In applications with abrasive slurries or hard particulates, such as mining or some chemical processes, the seat can be eroded or damaged, leading to premature failure.

Performance Under Pressure

At higher temperatures, PTFE can become more susceptible to "creep" or deformation under high-pressure conditions. This can compromise the valve's sealing capability, so it's critical to operate within the manufacturer's specified pressure-temperature limits.

Cost Considerations

PTFE is a premium performance polymer. It is typically more expensive than common elastomers like EPDM or Buna-N, making it an unnecessary expense for simpler applications like general water service.

Making the Right Choice for Your Application

Selecting the correct seat material is a function of your specific process conditions and operational goals.

- If your primary focus is handling aggressive chemicals or solvents: PTFE is the default and safest choice due to its near-universal chemical resistance.

- If your primary focus is high-purity or sanitary processes: PTFE's non-stick, non-contaminating surface is essential for preventing product contamination.

- If your primary focus is cost-effectiveness for general utilities (like air or water): A different elastomer like EPDM often provides sufficient performance at a lower cost.

- If your primary focus is managing abrasive slurries: You should evaluate harder, more resilient materials specifically designed for abrasion resistance.

Ultimately, choosing PTFE for an electric actuated butterfly valve is a strategic decision to maximize reliability, safety, and performance in your most critical automated processes.

Summary Table:

| Key Property | Benefit for Electric Actuated Valves |

|---|---|

| Chemical Inertness | Resists degradation from aggressive media, ensuring safety and purity. |

| Thermal Stability | Maintains seal integrity and performance across a wide temperature range. |

| Low Friction | Reduces actuator torque requirements, minimizing wear and extending life. |

| Non-Stick Surface | Prevents media buildup and contamination, critical for high-purity processes. |

Optimize your critical flow control systems with KINTEK's precision PTFE components.

For demanding applications in the semiconductor, pharmaceutical, and chemical industries, the reliability of your electric actuated valves is paramount. KINTEK specializes in manufacturing high-performance, custom-fabricated PTFE seals, liners, and labware designed to meet the exacting standards of specialized industrial processes.

We ensure your automated systems achieve maximum uptime and safety through:

- Superior Material Performance: Our PTFE components provide the chemical resistance and stability your processes demand.

- Precision Engineering: We prioritize exact specifications for a perfect fit and reliable operation in your valve assemblies.

- Custom Fabrication: From initial prototypes to high-volume production runs, we deliver solutions tailored to your unique application.

Ready to enhance the reliability of your automated processes? Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can bring value to your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications