At its core, the preference for quad rings over O-rings in dynamic applications comes down to a superior design that directly counters the most common failure mode of O-rings in motion. Their unique four-lobed profile prevents the twisting that leads to spiral failure and allows for an effective seal with less friction-inducing pressure.

The central issue isn't just about preventing a leak; it's about ensuring reliability over millions of cycles. The O-ring's simple circular cross-section is prone to twisting and rolling in its groove during movement, while the quad ring's stable, X-shaped profile is specifically designed to resist this motion.

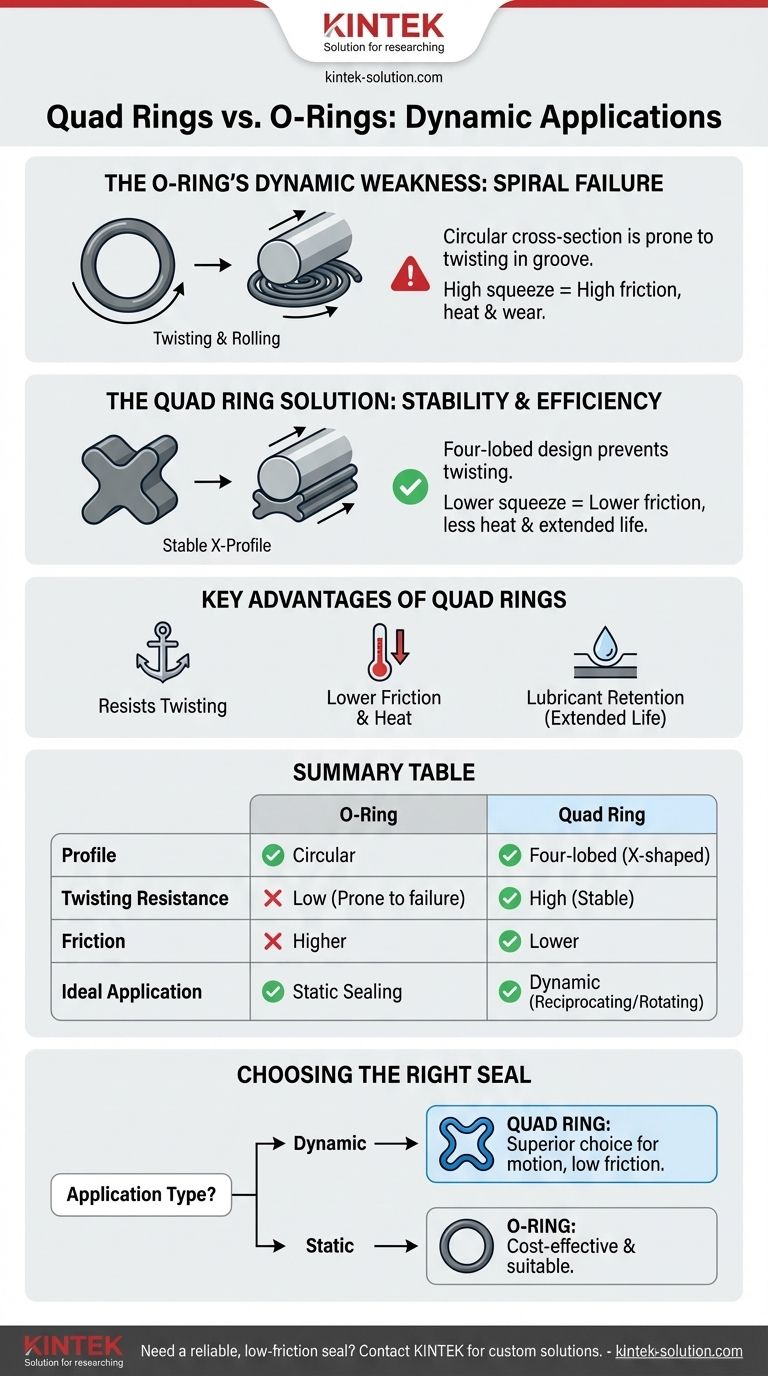

The Inherent Weakness of O-Rings in Motion

To understand why the quad ring excels, we must first analyze the fundamental vulnerability of the traditional O-ring in any application involving movement, whether it's reciprocating (back-and-forth) or rotating.

The Problem of "Spiral Failure"

An O-ring seals by being compressed into a groove, deforming to fill the gap. When a shaft or piston moves, the friction between the O-ring and the moving surface can cause the ring to roll or twist slightly within its groove.

Over many cycles, this slight twist can accumulate, causing the O-ring to bunch up and develop a spiral-like pattern along its length. This condition, known as spiral failure, creates stress points, leads to uneven wear, and ultimately results in seal failure and leakage.

High Squeeze Creates High Friction

For an O-ring to maintain a consistent seal during movement, it often requires a significant amount of compression, or "squeeze."

This high compressive force directly translates into higher friction between the seal and the moving hardware. This friction generates heat, accelerates wear on both the seal and the equipment, and reduces the overall efficiency of the system.

How the Quad Ring's Design Provides a Solution

The quad ring, also known as an X-ring, was engineered specifically to overcome the dynamic limitations of the O-ring. Its advantages stem directly from its distinct cross-sectional shape.

A Stable Profile Resists Twisting

The quad ring's four-lobed, X-shaped profile provides a much wider and more stable footprint within the sealing groove.

This inherent stability makes it extremely resistant to the rolling and twisting forces that cause spiral failure in O-rings. The seal stays put, ensuring consistent performance.

Sealing Effectively with Less Squeeze

The design features multiple sealing points—two on the inner diameter and two on the outer. This redundancy allows the quad ring to create a highly effective seal with significantly less compressive force than a standard O-ring.

The Direct Benefit of Lower Friction

Requiring less squeeze to seal directly results in lower friction. This is arguably the quad ring's most significant advantage in dynamic applications.

Lower friction means less heat generation, dramatically reduced wear, longer service life for the seal, and improved mechanical efficiency for the entire system.

Retaining Lubricant for Extended Life

The shallow grooves between the lobes on the seal's diameter serve a critical function. They act as small reservoirs that trap lubricant (like grease or oil).

This trapped lubricant ensures a consistent film between the seal and the moving surfaces, which is vital for minimizing friction and wear over the long term, especially in high-speed or frequently moving systems.

Understanding the Trade-offs

While superior in dynamic scenarios, the quad ring is not the automatic choice for every situation. Understanding the context is crucial for proper seal selection.

Static Sealing Performance

In a purely static application, where the two sealed surfaces do not move relative to each other, the O-ring's primary failure mode (spiral failure) is irrelevant.

For these non-moving, high-pressure situations, a standard O-ring or even a square ring often provides an equally effective seal at a lower cost.

Cost and Availability

The manufacturing process for quad rings is more complex than for O-rings. As a result, they can be more expensive and may not be as readily available in the vast range of sizes and material compounds as the ubiquitous O-ring.

Choosing the Right Seal for Your Application

Your final decision should be driven entirely by the demands of the application itself.

- If your primary focus is a dynamic application (reciprocating, oscillating, or rotating): The quad ring is the superior technical choice for its resistance to spiral failure and its low-friction characteristics.

- If your primary focus is a static, face-to-face seal: An O-ring is typically a more cost-effective and perfectly suitable solution.

- If your primary focus is maximizing efficiency and service life in a moving system: The quad ring's ability to seal with less squeeze and retain lubricant makes it the definitive winner.

Ultimately, selecting the seal whose design geometry best matches the motion of your application is the key to engineering a reliable and durable system.

Summary Table:

| Feature | O-Ring | Quad Ring |

|---|---|---|

| Profile | Circular | Four-lobed (X-shaped) |

| Resistance to Twisting | Low, prone to spiral failure | High, stable in groove |

| Friction | Higher (requires more squeeze) | Lower (seals with less squeeze) |

| Ideal Application | Static sealing | Dynamic (reciprocating, rotating) sealing |

Need a reliable, low-friction seal for your dynamic application?

KINTEK specializes in manufacturing high-performance PTFE seals and components, including custom quad rings, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals resist spiral failure and minimize wear, extending the life of your equipment.

Contact us today to discuss your custom sealing solution—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the installation advantages of PTFE expansion bellows? Reduce Labor, Time, and Equipment Needs

- What makes PTFE special in terms of friction? Achieve Unmatched Efficiency with Self-Lubricating Components

- What are the key benefits of using PTFE in seals? Achieve Unmatched Reliability in Extreme Conditions

- How does expanded PTFE sheet compare to other PTFE-based gaskets? Discover the Superior Sealing Solution

- What are the key advantages of PTFE oil scraper rings? Superior Sealing, Low Friction & Durability

- What are the key properties of PTFE that make it useful in sports equipment? Boost Speed and Durability

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- What are some tips for successfully machining PTFE? Master Precision Cuts for Soft, Heat-Sensitive Material