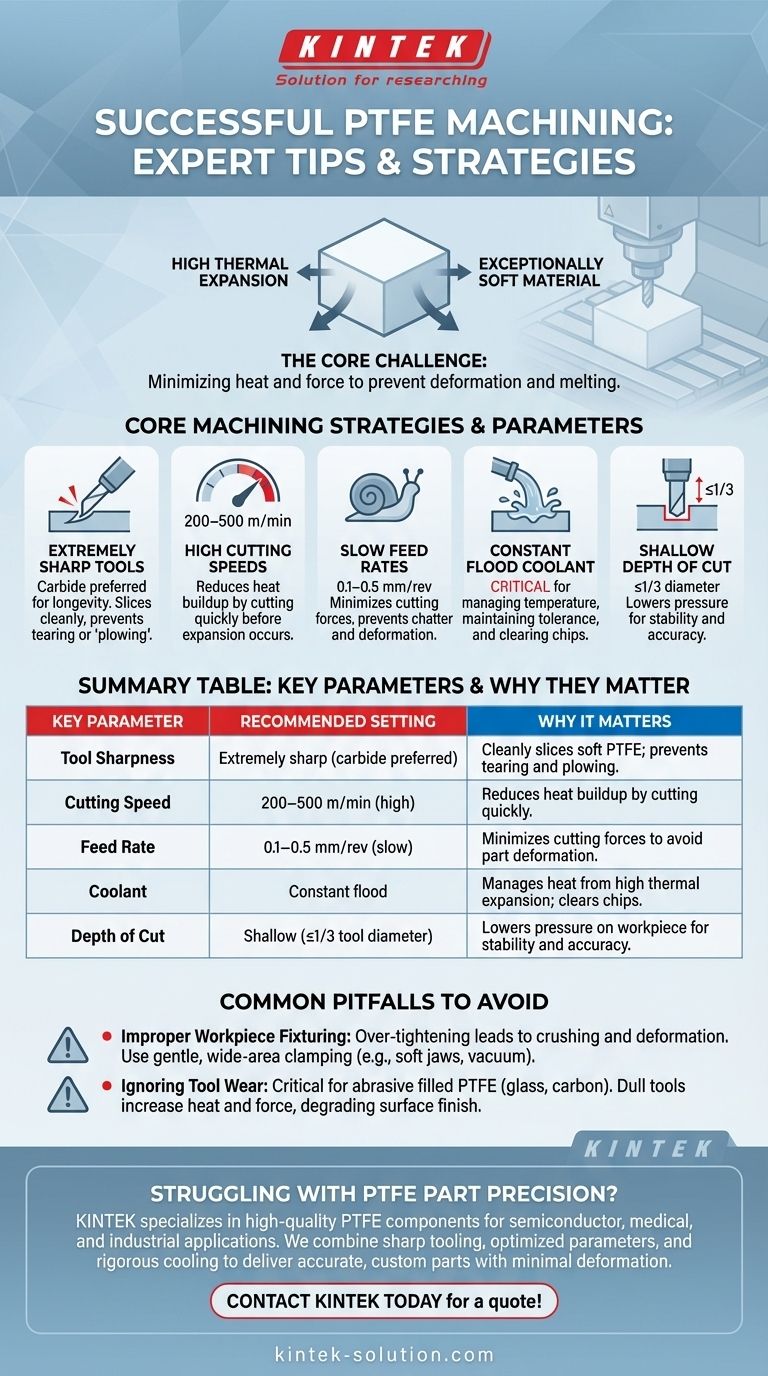

To machine PTFE successfully, you must use extremely sharp tools, high cutting speeds, slow feed rates, and a shallow depth of cut. Because PTFE is soft and expands significantly with heat, applying a constant flood of coolant is critical to manage temperature, prevent deformation, and achieve tight dimensional tolerances.

The core challenge in machining PTFE is not its hardness, but its softness, low strength, and high thermal expansion. Success depends entirely on minimizing cutting forces and heat buildup to prevent the material from deforming or melting during the process.

The Unique Challenges of Machining PTFE

Polytetrafluoroethylene (PTFE), often known by the brand name Teflon, presents a unique set of machining challenges. Understanding these properties is the first step toward producing accurate parts.

Managing Softness and Deformation

PTFE is an exceptionally soft material. This means it can easily be compressed or distorted by dull cutting tools or excessive clamping pressure from fixtures.

Instead of being cut cleanly, the material can be pushed or "plowed" by a tool that is not sharp enough, leading to poor surface finish and dimensional inaccuracy.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes far more than metals or even many other plastics.

Even a small amount of heat generated from the cutting process can cause the workpiece to expand, throwing off critical dimensions. When the part cools, it will be smaller than intended, making tolerance control a primary concern.

The Impact of Fillers (Glass, Carbon, Graphite)

To improve its mechanical properties, PTFE is often blended with fillers like glass, carbon, or graphite. These PTFE compounds offer better wear resistance, greater stability, and reduced deformation under load.

However, these fillers also make the material significantly more abrasive. Machining filled PTFE will cause rapid tool wear, requiring harder and more durable cutting tools to maintain sharpness and accuracy.

Core Machining Strategies and Parameters

Achieving a high-quality result with PTFE requires a deliberate approach that directly counteracts its natural properties.

Tool Selection is Critical

Your cutting tools must be extremely sharp. A sharp edge slices through the soft material cleanly, whereas a dull edge will tear it.

For virgin PTFE, high-speed steel (HSS) tools can work, but carbide-tipped tools are a better choice for longevity and sharpness. For abrasive filled PTFE grades, carbide is essential to resist wear.

Optimizing Speeds and Feeds

The general rule for PTFE is high speed, low feed.

- Cutting Speeds: Maintain high cutting speeds, typically in the range of 200 to 500 m/min (up to 1000 m/min in some cases). This allows the tool to cut the material before significant heat can build up.

- Feed Rates: Use slower feed rates, around 0.1 to 0.5 mm/rev. A slow feed reduces the cutting forces exerted on the material, preventing it from chattering or deforming.

The Role of Coolant

A constant, generous supply of coolant is non-negotiable. Coolant serves two primary functions.

First, it manages heat at the cutting point, preventing thermal expansion and preserving dimensional accuracy. Second, it helps clear away chips, which can otherwise become gummy and wrap around the tool.

Controlling the Depth of Cut

Use a shallow depth of cut. A good guideline is to not exceed one-third of the cutting tool's diameter.

This minimizes the pressure on the workpiece, further reducing the risk of deformation and tool chatter, which is common with soft materials.

Common Pitfalls to Avoid

Success with PTFE is often about avoiding common mistakes related to its unique properties.

Improper Workpiece Fixturing

Over-tightening a vise or clamp can easily crush or deform a PTFE part before the first cut is even made.

Use fixtures that distribute clamping force over a wide surface area, such as soft jaws or vacuum fixtures, to hold the workpiece securely without distortion.

Ignoring Tool Wear

This is especially critical with filled PTFE. As the tool dulls from the abrasive fillers, the cutting forces increase, heat builds up, and the surface finish degrades rapidly.

Regularly inspect your tools for sharpness and replace them before they cause problems. A sharp tool is your most important asset.

Making the Right Choice for Your Goal

Your approach should be tailored to the specific grade of PTFE you are working with and the precision your final part requires.

- If your primary focus is machining virgin (unfilled) PTFE: Prioritize extremely sharp tools and aggressive cooling to manage its softness and high thermal expansion.

- If your primary focus is machining filled PTFE (glass, carbon): Use hard, wear-resistant carbide tooling and monitor it closely for dulling caused by the abrasive fillers.

- If your primary focus is achieving high-precision tolerances: Emphasize process stability above all—secure but gentle fixturing, consistent coolant flow, and finely tuned speeds and feeds are essential.

By respecting the material's unique characteristics, you can reliably produce accurate, high-quality PTFE components.

Summary Table:

| Key Parameter | Recommended Setting | Why It Matters |

|---|---|---|

| Tool Sharpness | Extremely sharp (carbide preferred) | Cleanly slices soft PTFE; prevents tearing and plowing. |

| Cutting Speed | 200–500 m/min (high) | Reduces heat buildup by cutting quickly. |

| Feed Rate | 0.1–0.5 mm/rev (slow) | Minimizes cutting forces to avoid part deformation. |

| Coolant | Constant flood | Manages heat from high thermal expansion; clears chips. |

| Depth of Cut | Shallow (≤1/3 tool diameter) | Lowers pressure on workpiece for stability and accuracy. |

Struggling with PTFE part precision? KINTEK specializes in machining high-quality PTFE components (seals, liners, labware) for semiconductor, medical, and industrial applications. We combine sharp tooling, optimized parameters, and rigorous cooling to deliver custom parts—from prototypes to high-volume orders—with exact tolerances and minimal deformation. Let our expertise solve your PTFE challenges. Contact KINTEK today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers