In short, Polytetrafluoroethylene (PTFE) is used in sports equipment primarily for its exceptionally low friction. Known commercially as Teflon, its unique "non-stick" quality reduces resistance between moving parts and surfaces, directly enhancing speed, efficiency, and durability in a wide range of athletic gear.

The core reason PTFE is valued in sports is not as a structural material, but as a high-performance surface modifier. It is applied as a coating, additive, or liner to create an incredibly slick and durable interface, allowing equipment to glide, slide, and move with minimal resistance.

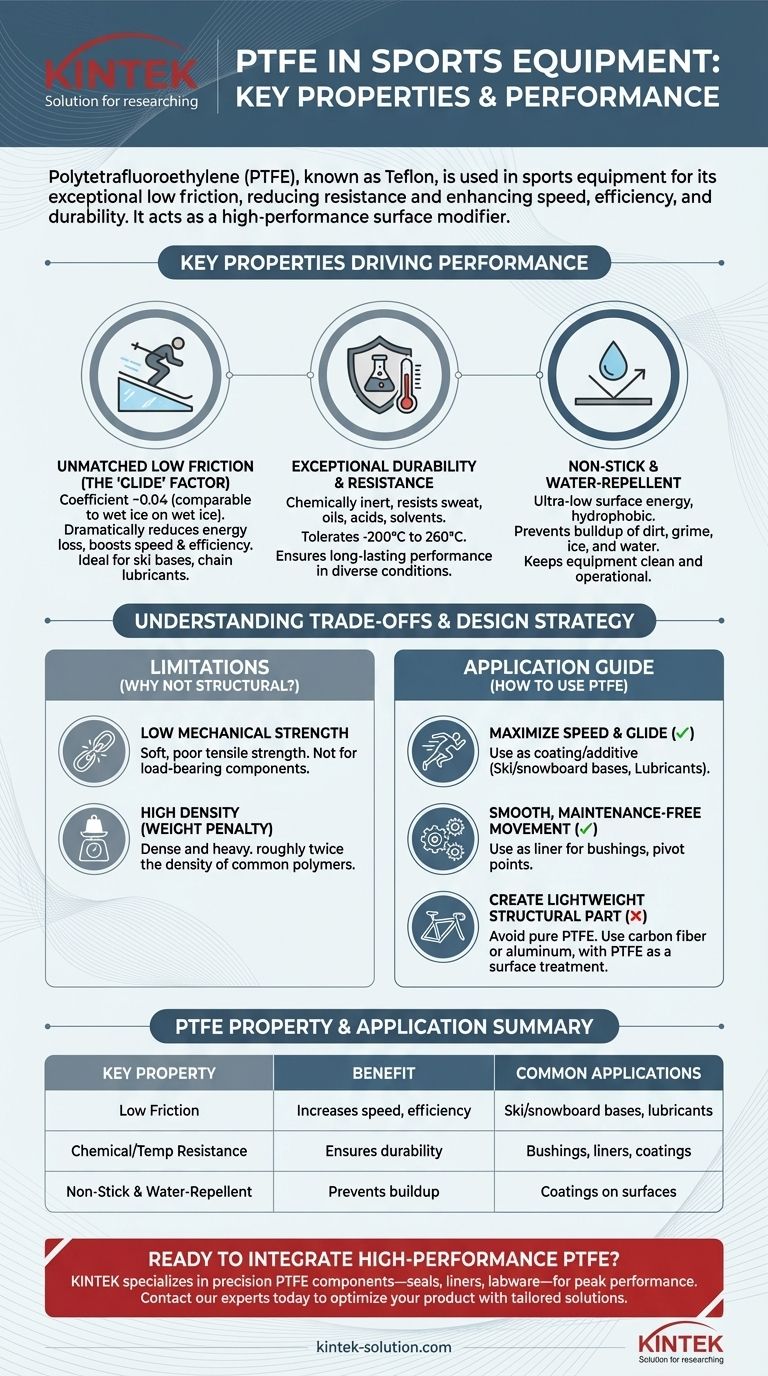

The Core Properties Driving Performance

PTFE's value comes from a unique combination of properties. While its low friction is the most famous, its chemical stability and surface characteristics are equally critical for performance in demanding athletic environments.

Unmatched Low Friction (The "Glide" Factor)

The single most important property of PTFE is its extremely low coefficient of friction, which is approximately 0.04. This is one of the lowest values of any known solid material, comparable to wet ice sliding on wet ice.

This property provides a distinct performance advantage. When applied to surfaces like ski bases or as an additive in chain lubricants, it dramatically reduces the energy lost to friction, translating directly into greater speed and efficiency.

Exceptional Durability and Resistance

PTFE is almost completely chemically inert. It resists degradation from virtually all common chemicals, including acids, oils, and solvents.

For sports equipment, this means it stands up to sweat, cleaning agents, lubricants, and environmental exposure without breaking down. This chemical stability, combined with its tolerance for a wide range of temperatures (-200°C to 260°C), ensures the material remains effective and durable across diverse conditions.

The Non-Stick and Water-Repellent Surface

PTFE has an ultra-low surface energy, which is why materials do not stick to it. It is also hydrophobic, meaning it actively repels water.

In practice, this prevents the buildup of dirt, grime, ice, and water on equipment. A snowboard base with PTFE won't have snow sticking to it, and a bicycle chain with a PTFE-based lubricant will shed mud and water more effectively, maintaining smooth operation.

Understanding the Trade-offs: Why PTFE Isn't Used Everywhere

While its surface properties are elite, PTFE has significant limitations that prevent its use as a primary structural material in sports equipment. Understanding these trade-offs is key to appreciating its specific role.

Low Mechanical Strength

PTFE is a relatively soft material with poor tensile strength and abrasion resistance on its own. It cannot be used to build a strong, load-bearing component like a bicycle frame or a ski core.

This is why PTFE is almost always used as a coating, a thin liner inside a bushing, or an additive blended into other materials (like waxes or oils). It enhances a surface but relies on another material for structural integrity.

High Density (The Weight Penalty)

Compared to many other performance plastics, PTFE is quite dense and therefore heavy. Its specific density is roughly twice that of common polymers like polypropylene.

In sports like cycling, running, or aerospace-influenced designs where every gram matters, this high density is a major drawback. This reinforces its use in very small quantities or thin layers where the friction-reducing benefits outweigh the slight increase in weight.

How to Apply This to Your Design

Your choice to use PTFE should be strategic and focused on solving a specific friction or durability challenge, not a structural one.

- If your primary focus is maximizing speed and glide: Use PTFE as a coating or a key additive in waxes and lubricants for applications like ski bases, snowboard bases, or bicycle chains.

- If your primary focus is smooth, maintenance-free movement: Use PTFE as a liner for bushings and pivot points in components like suspension systems or bearing assemblies.

- If your primary focus is creating a lightweight structural part: Avoid pure PTFE and look to materials like carbon fiber, aluminum, or other engineering plastics, using PTFE only as a targeted surface treatment if needed.

Ultimately, PTFE is a specialist material used to perfect the interaction between surfaces, enabling equipment to perform at the absolute peak of its potential.

Summary Table:

| Key PTFE Property | Benefit in Sports Equipment | Common Applications |

|---|---|---|

| Low Friction (Coefficient ~0.04) | Increases speed and efficiency by reducing resistance. | Ski/snowboard bases, bicycle chain lubricants. |

| Chemical & Temperature Resistance | Ensures durability against sweat, oils, and extreme conditions. | Bushings, liners, coatings exposed to elements. |

| Non-Stick & Water-Repellent | Prevents buildup of dirt, ice, and mud for consistent performance. | Coatings on various equipment surfaces. |

Ready to integrate high-performance PTFE into your sports equipment designs?

KINTEK specializes in the precision manufacturing of PTFE components—including custom seals, liners, and labware—for industries demanding peak performance and durability. Whether you need a prototype for testing or high-volume production for your latest gear, our expertise ensures a solution that enhances glide, reduces maintenance, and stands up to tough conditions.

Contact our experts today to discuss how we can help optimize your product's performance with tailored PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are Teflon sheets and what are they made of? The Ultimate Guide to PTFE Properties

- What is PTFE and why is it suitable for O-rings? Achieve Unmatched Chemical & Temperature Resistance

- How do PTFE rotary shaft seals reduce maintenance costs? Slash Downtime & Labor Expenses

- What industries benefit from using PTFE rod in bearings and bushings? Enhance Performance in Demanding Environments

- What is the primary function of a PTFE lined butterfly valve? Control Corrosive, Toxic, and High-Purity Fluids

- What are critical installation practices for PTFE O-rings? Avoid Leaks and Ensure a Perfect Seal

- What are the key properties of Teflon PTFE? Unlocking Unmatched Chemical & Thermal Resistance

- What lip style options are available for high-pressure PTFE seals? Choose the Right Seal for Extreme Conditions