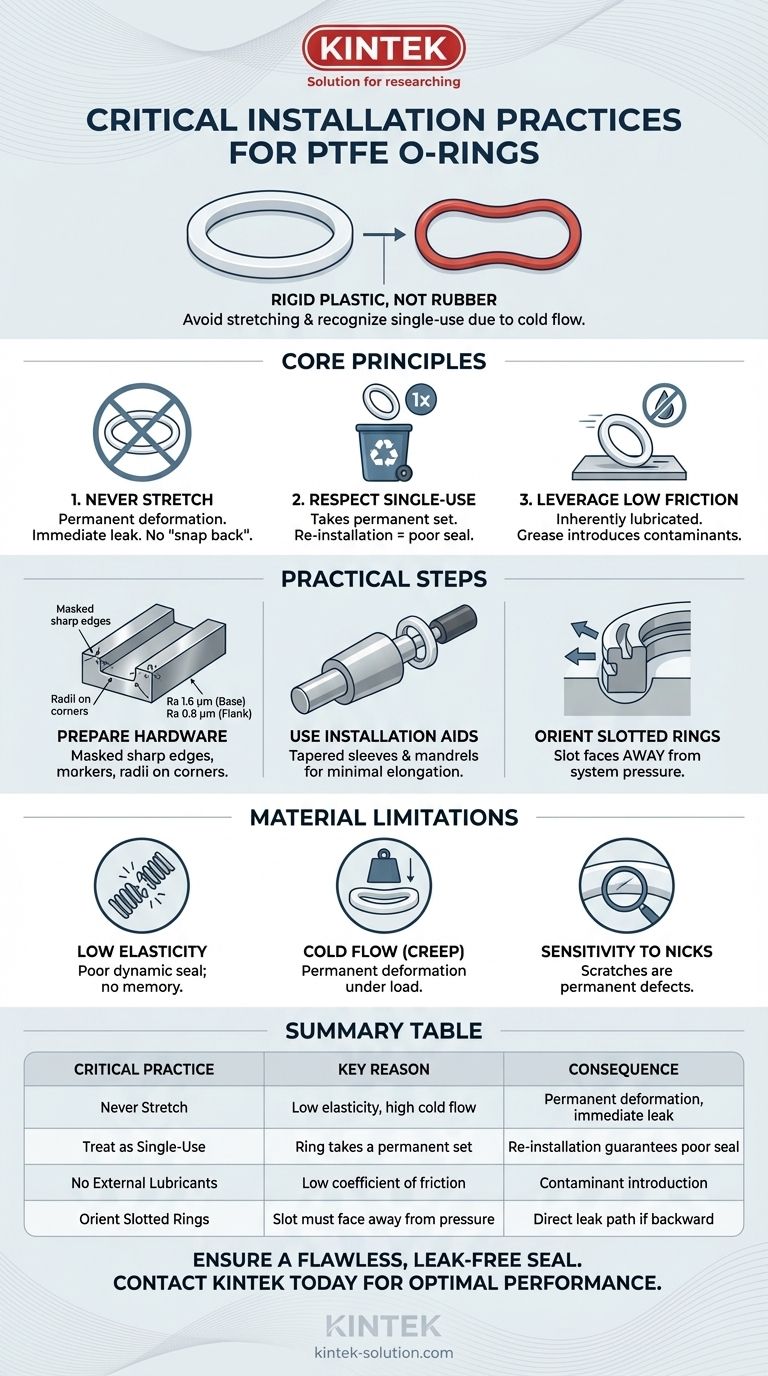

To properly install a PTFE O-ring, you must handle it as a rigid plastic component, not a flexible rubber one. The most critical practices are to avoid any stretching, which causes permanent damage, and to recognize that they are single-use only due to their tendency to permanently deform under pressure (a phenomenon known as cold flow).

The fundamental challenge with PTFE O-rings is that their exceptional chemical and thermal resistance comes from a material that behaves more like a soft plastic than a rubber. Successful installation depends entirely on respecting this low elasticity to prevent irreversible deformation and ensure a reliable seal.

The Core Principles of PTFE O-Ring Installation

Understanding the "why" behind the rules is essential for preventing seal failure. PTFE's material properties are fundamentally different from standard elastomers like nitrile or FKM (Viton®).

Principle 1: Never Stretch the Ring

Unlike rubber, PTFE has very low elasticity and high cold flow, or creep. Stretching a PTFE O-ring, even slightly, will permanently deform it.

The ring will not "snap back" to its original dimensions, resulting in a loose fit and an immediate leak path. This is the single most common cause of installation failure.

Principle 2: Respect the "Single-Use" Rule

Once a PTFE O-ring is installed and compressed, it conforms to the groove through cold flow. It takes a permanent "set" and will not rebound to its original shape upon removal.

Re-installing a used PTFE ring guarantees a poor seal. They must be considered single-use components and replaced every time the joint is disassembled.

Principle 3: Leverage its Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This inherent lubricity means that no external lubricants or greases are required for installation.

Adding grease is unnecessary and can introduce contaminants into the system, potentially compromising the seal or the media it contains.

Practical Steps for a Flawless Installation

A successful seal begins before the O-ring is ever touched. Proper hardware preparation and handling are non-negotiable.

Prepare the Hardware

All sharp edges and threads that the O-ring must pass over should be masked or covered. Mating hardware should have corner breaks or radii to prevent nicking or gouging the ring.

For optimal performance, groove surfaces must meet specific finish requirements. A rough surface can abrade the ring, while a polished one may not hold it securely. Aim for a groove base roughness of Ra 1.6 µm and flank roughness of Ra 0.8 µm.

Use Installation Aids

Because stretching is forbidden, specialized tools are often necessary, especially for internal (piston) or closed grooves.

Use tapered sleeves, mandrels, or other guiding tools to gently slide the ring over sharp features and ease it into its groove with minimal elongation.

Orient Slotted Rings Correctly

Some PTFE O-rings are "slotted" or "scarf-cut" to provide a degree of flexibility during installation. This design feature has a critical orientation requirement.

The slot must always be positioned to face away from system pressure. Installing it backward negates its purpose and creates a direct leak path.

Understanding the Material's Limitations

Acknowledging the trade-offs of PTFE is crucial for selecting it for the right application and ensuring its success. Its strengths in harsh environments are balanced by its mechanical limitations.

The Challenge of Low Elasticity

PTFE's lack of "memory" means it is poorly suited for dynamic applications or those requiring frequent assembly and disassembly. It provides an excellent static seal but does not have the resilience of rubber.

The Reality of Cold Flow (Creep)

Under sustained compressive load, especially at elevated temperatures, the PTFE material will slowly and permanently deform. This property is why initial installation is so critical—the seal that is formed upon initial compression is the final shape the ring will hold.

Sensitivity to Nicks and Gouges

A scratch on a rubber O-ring might self-heal due to the material's elasticity. A similar scratch on a PTFE O-ring is a permanent defect and a potential failure point, as the material cannot rebound to close the gap.

Making the Right Choice for Your Goal

Your installation focus should align with the demands of the application to ensure long-term reliability.

- If your primary focus is static chemical sealing: Ensure the groove is perfectly clean and the ring is placed without any surface damage, as it will not self-heal.

- If you are installing a piston or rod seal: The most critical factor is using installation aids to guide the ring into its groove with minimal elongation.

- If you are using a slotted PTFE ring: Double-check that the slot is oriented to face away from system pressure to ensure it provides the intended flexibility.

Properly handling PTFE's unique properties during installation is the key to unlocking its exceptional sealing performance in demanding environments.

Summary Table:

| Critical Practice | Key Reason | Consequence of Error |

|---|---|---|

| Never Stretch the Ring | PTFE has low elasticity and high cold flow. | Permanent deformation and immediate leak path. |

| Treat as Single-Use | Ring takes a permanent set under compression. | Re-installation guarantees a poor seal. |

| No External Lubricants | PTFE has an inherently low coefficient of friction. | Introduction of contaminants into the system. |

| Orient Slotted Rings Correctly | Slot must face away from system pressure. | Creates a direct leak path if installed backward. |

Ensure a flawless, leak-free seal in your most demanding applications.

PTFE O-rings are critical for sealing in harsh chemical and thermal environments, but their installation requires precision and expertise. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom O-rings, seals, and labware for the semiconductor, medical, and industrial sectors.

Our team understands the unique properties of PTFE and can provide the right components and technical guidance for your specific needs, from prototypes to high-volume production.

Don't risk seal failure. Contact KINTEK today to discuss your PTFE component requirements and ensure optimal performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions