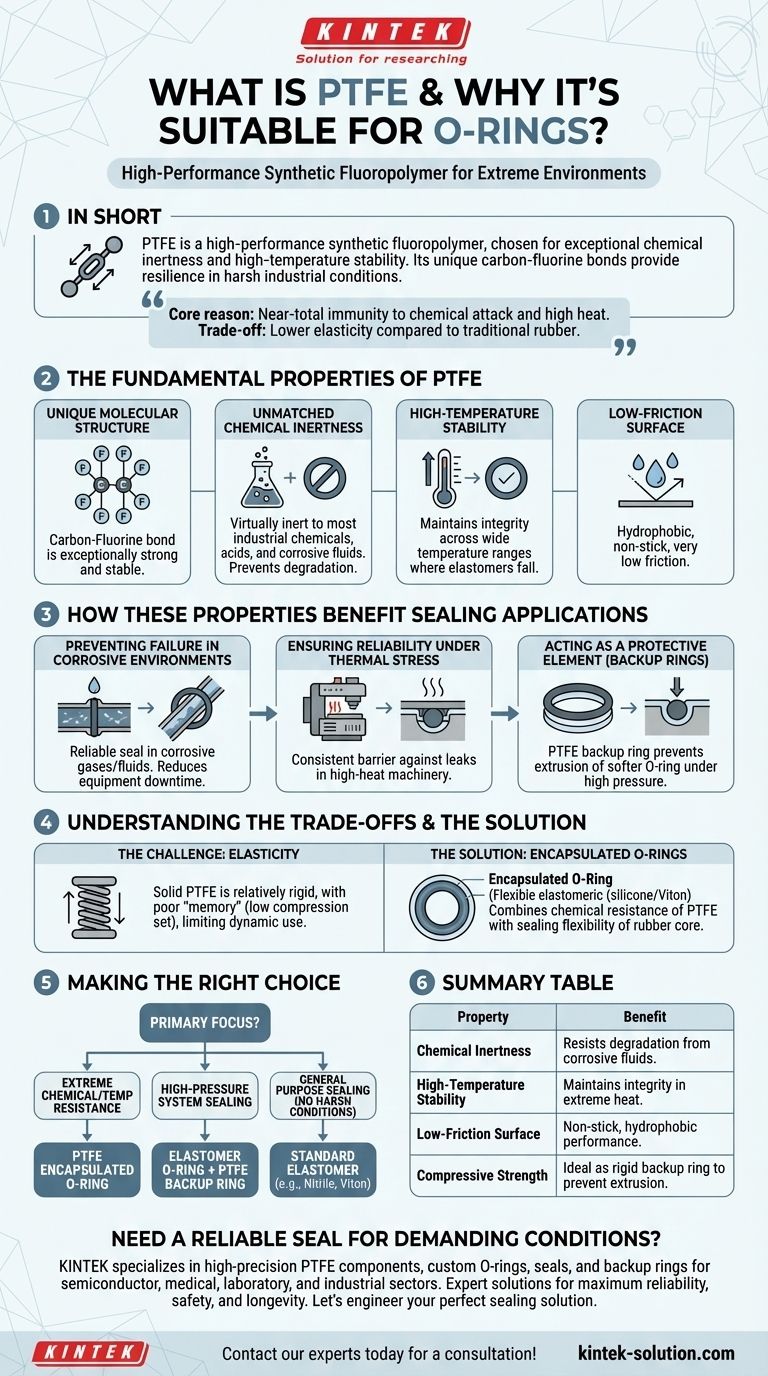

In short, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer. It is chosen for O-rings and seals primarily due to its exceptional chemical inertness and ability to withstand extreme temperatures. Its unique molecular structure, featuring incredibly strong carbon-fluorine bonds, makes it resilient in harsh industrial environments where conventional materials would quickly fail.

The core reason to select PTFE for sealing is its near-total immunity to chemical attack and high heat. However, this unmatched resistance comes at the cost of lower elasticity compared to traditional rubber, a critical trade-off that dictates its specific applications.

The Fundamental Properties of PTFE

A Unique Molecular Structure

PTFE is a polymer built from a carbon-only backbone completely surrounded by fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This molecular arrangement is the source of nearly all of PTFE's valuable characteristics.

Unmatched Chemical Inertness

Because of its strong molecular bonds, PTFE is virtually inert. It does not react with the vast majority of industrial chemicals, acids, and corrosive fluids.

This non-reactivity prevents the seal from degrading, swelling, or failing when exposed to aggressive substances, ensuring long-term reliability.

High-Temperature Stability

PTFE maintains its integrity and dimensional stability across a wide range of temperatures. It can perform reliably in high-temperature applications where many standard elastomers would soften or decompose.

Low-Friction Surface

This material is also known for its hydrophobic (water-repelling) and non-stick properties. Its surface is extremely low-friction, which is a significant advantage in certain sealing applications.

How These Properties Benefit Sealing Applications

Preventing Failure in Corrosive Environments

The primary benefit of a PTFE O-ring is its ability to create a reliable seal in systems handling corrosive gases or fluids.

By preventing premature seal failure, it reduces equipment downtime and increases operational safety and profitability in demanding sectors.

Ensuring Reliability Under Thermal Stress

In machinery that operates at high temperatures, PTFE seals will not degrade, providing a consistent and effective barrier against leaks. This makes it ideal for applications requiring high wear resistance under thermal load.

Acting as a Protective Element

Due to its hardness and compressive strength, PTFE is often used to create backup rings. These rings are installed alongside a softer, more traditional O-ring (like Nitrile or Viton).

The PTFE backup ring provides structural support, preventing the primary O-ring from being physically pushed, or "extruded," out of its groove under high pressure.

Understanding the Trade-offs

The Challenge of Elasticity

Pure, solid PTFE is not an elastomer. It is a relatively rigid plastic with poor "memory," meaning it does not spring back to its original shape well after being compressed.

This low elasticity, known as poor compression set, means a solid PTFE O-ring may not maintain a tight seal after repeated pressure cycles, limiting its use as a standalone, dynamic seal.

The Solution: Encapsulated O-Rings

To overcome this limitation, PTFE encapsulated O-rings are widely used. These combine the best of both worlds.

They feature a flexible, elastomeric core (like silicone or Viton) that provides excellent elasticity, which is then seamlessly enclosed in a thin, protective PTFE outer shell. This design delivers the chemical resistance of PTFE with the sealing flexibility of rubber.

Making the Right Choice for Your Application

Selecting the correct sealing material requires understanding your primary operational challenge.

- If your primary focus is extreme chemical or temperature resistance: A PTFE encapsulated O-ring is the superior choice for combining resilience and sealing force.

- If your primary focus is sealing in a high-pressure system: Use a standard elastomer O-ring supported by a solid PTFE backup ring to prevent extrusion.

- If your primary focus is general-purpose sealing without harsh chemicals or temperatures: A standard elastomer like Nitrile or Viton is often more cost-effective and suitable.

Ultimately, understanding PTFE's unique balance of chemical immunity and physical rigidity empowers you to engineer a more reliable and durable sealing solution.

Summary Table:

| Property | Benefit for O-Rings |

|---|---|

| Chemical Inertness | Resists degradation from corrosive fluids and gases. |

| High-Temperature Stability | Maintains integrity in extreme heat where elastomers fail. |

| Low-Friction Surface | Provides non-stick, hydrophobic performance. |

| Compressive Strength | Ideal for use as a rigid backup ring to prevent extrusion. |

Need a Reliable Seal for Demanding Conditions?

PTFE's unique properties make it the go-to material for sealing solutions in the most challenging environments. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom O-rings, seals, and backup rings.

We serve the semiconductor, medical, laboratory, and industrial sectors, where failure is not an option. Whether you require a standard part or a custom-fabricated solution—from prototypes to high-volume orders—our expertise ensures you get a seal that delivers maximum reliability, safety, and longevity.

Let's engineer your perfect sealing solution. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating