At its core, a PTFE lined butterfly valve is a quarter-turn valve used for both shutting off and regulating flow, with a critical specialization: its internal components are fully isolated from the process fluid by a corrosion-proof Polytetrafluoroethylene (PTFE) liner. This design makes it the default choice for controlling highly corrosive, toxic, or high-purity media that would quickly degrade standard valves.

The decision to use a PTFE lined butterfly valve is not just about controlling flow; it's a strategic choice for ensuring system integrity, safety, and longevity when handling chemically aggressive fluids. The lining acts as a protective shield, preventing corrosion of the valve's structural body.

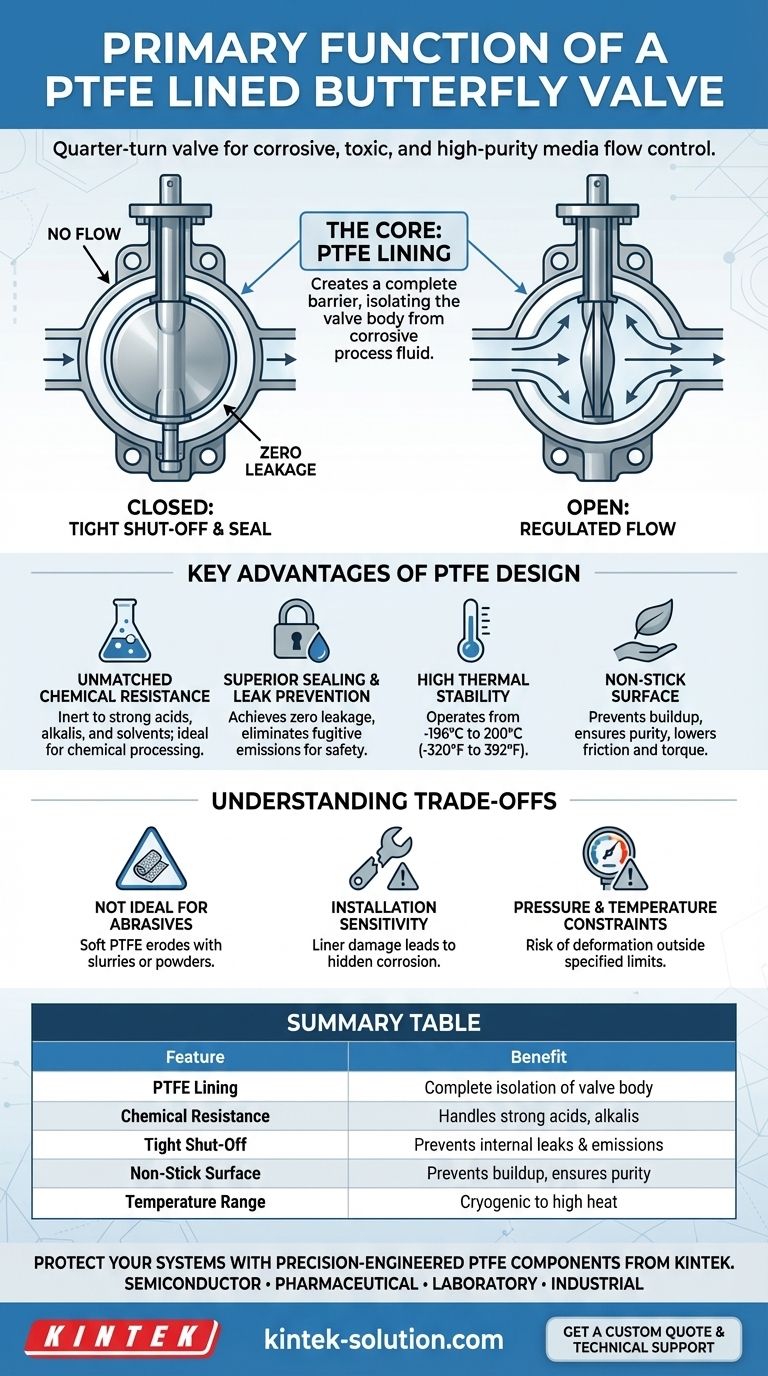

How the Design Delivers Performance

A PTFE lined butterfly valve combines a simple, proven mechanism with a highly advanced material to solve a difficult industrial challenge. Understanding both parts is key to appreciating its function.

The Core Butterfly Mechanism

The valve operates on a simple quarter-turn principle. A circular disc is mounted on a stem in the middle of the flow path.

When the valve is open, the disc is rotated parallel to the flow, creating a largely unobstructed path. To close it, the disc is rotated 90 degrees to be perpendicular to the flow, pressing against the PTFE seat to create a tight seal.

The Critical Role of the PTFE Lining

The true innovation is the PTFE liner. This non-reactive, engineered plastic is molded to the interior surfaces of the valve body.

This liner creates a complete barrier between the fluid and the valve's metal body (typically ductile iron or carbon steel). The disc and sometimes the stem are also encapsulated in PTFE, ensuring no wetted metal parts are exposed to the corrosive media.

Key Advantages of the PTFE Design

The properties of PTFE directly translate into tangible operational benefits, making these valves indispensable in certain applications.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals, including strong acids, alkalis, and solvents. This makes it the ideal material for chemical processing and pharmaceutical applications where media compatibility is non-negotiable.

Superior Sealing and Leak Prevention

These valves are engineered for tight shut-off, often achieving zero leakage. The PTFE seal effectively prevents internal leaks within the piping system and eliminates fugitive emissions, which is critical for handling toxic fluids and ensuring environmental compliance.

High Thermal Stability

PTFE offers a very wide operating temperature range, with some designs capable of handling media from cryogenic temperatures (-196°C) up to 200°C (-320°F to 392°F).

Non-Stick Surface for Purity and Efficiency

The low-friction, non-stick surface of PTFE prevents media from adhering to and building up on the valve's internal parts. This ensures product purity, minimizes pressure drop, and guarantees smooth, low-torque operation over the valve's lifespan.

Understanding the Trade-offs

While highly effective, PTFE lined valves are a specialized tool. Understanding their limitations is crucial for proper application.

Not Ideal for Abrasive Media

PTFE is a relatively soft material. It is not suitable for services containing abrasive particles, slurries, or powders, as these can quickly erode the liner and cause the valve to fail.

Sensitivity to Installation Damage

The integrity of the PTFE liner is paramount. Scratches or gouges that occur during installation can create a pathway for corrosive media to reach the valve body, leading to hidden corrosion and premature failure. Careful handling is essential.

Pressure and Temperature Constraints

While the temperature range is wide, PTFE can be subject to deformation or creep under high-pressure and high-temperature combinations. It's critical to operate the valve strictly within the manufacturer's specified pressure/temperature curve.

How to Apply This to Your Project

The choice of a valve is a critical design decision. Use these guidelines to determine if a PTFE lined butterfly valve is the right solution for your specific goal.

- If your primary focus is handling corrosive, toxic, or high-purity media: The PTFE lined butterfly valve is the definitive choice for its chemical inertness and protective barrier.

- If your primary focus is cost-efficiency for non-corrosive fluids (like water or air): A standard resilient-seated or high-performance butterfly valve is a more economical and suitable option.

- If your primary focus is managing abrasive slurries: Investigate valves specifically designed for abrasion, such as knife gate valves or those with hardened metal seats, instead of a PTFE lined valve.

Ultimately, selecting a PTFE lined butterfly valve is an investment in the long-term reliability and safety of your most demanding fluid handling systems.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Lining | Complete isolation of valve body from corrosive media |

| Chemical Resistance | Handles strong acids, alkalis, and solvents |

| Tight Shut-Off | Prevents internal leaks and fugitive emissions |

| Non-Stick Surface | Prevents media buildup and ensures product purity |

| Temperature Range | Operates from cryogenic (-196°C) to high heat (200°C) |

Protect your critical fluid systems with precision-engineered PTFE components from KINTEK.

Our PTFE lined butterfly valves are designed for maximum reliability in the most demanding environments, including semiconductor, pharmaceutical, laboratory, and industrial applications. We specialize in custom fabrication, from initial prototypes to high-volume production runs, ensuring a perfect fit for your specific chemical and purity requirements.

Contact us today to discuss your project and discover how our expertise in precision PTFE manufacturing can enhance your system's safety, integrity, and longevity.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry