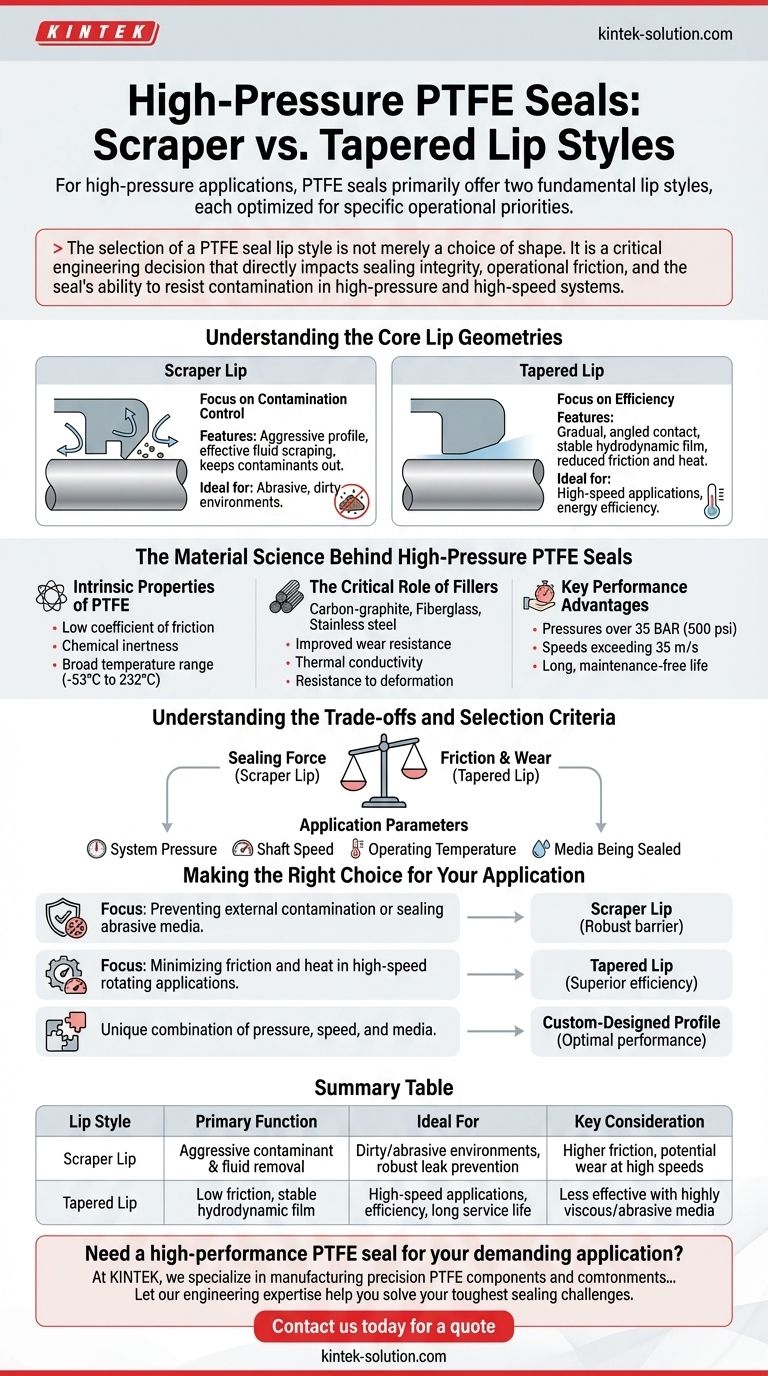

For high-pressure applications, PTFE seals primarily offer two fundamental lip styles: the traditional scraper lip, designed for aggressive fluid and contaminant removal, and the tapered lip, which provides a more efficient seal with lower friction. The specific geometry is chosen based on the balance required between sealing effectiveness, friction, and wear in a given operational environment.

The selection of a PTFE seal lip style is not merely a choice of shape. It is a critical engineering decision that directly impacts sealing integrity, operational friction, and the seal's ability to resist contamination in high-pressure and high-speed systems.

Understanding the Core Lip Geometries

The geometry of the seal lip is the primary factor dictating its functional behavior. Each design is optimized for a different set of performance priorities.

The Scraper Lip: A Focus on Contamination Control

A scraper lip (or traditional lip) features a more aggressive profile. Its primary function is to scrape fluid from a shaft or rod, making it highly effective at preventing leaks.

This design is also excellent for keeping external contaminants, such as dirt and debris, from entering the system. This makes it a robust choice for abrasive or dirty environments.

The Tapered Lip: A Focus on Efficiency

A tapered lip has a more gradual, angled contact point. This geometry is engineered to create a stable hydrodynamic film, which significantly reduces friction and heat generation.

This lower friction translates to less wear on both the seal and the shaft, extending the service life of the components. It is the preferred choice for high-speed applications where efficiency is paramount.

The Material Science Behind High-Pressure PTFE Seals

The choice of lip style is only part of the equation. The unique properties of Polytetrafluoroethylene (PTFE), often enhanced with fillers, are what enable these designs to function under extreme conditions.

Intrinsic Properties of PTFE

PTFE is inherently suited for demanding sealing applications due to its extremely low coefficient of friction, broad chemical inertness, and wide operating temperature range (-53°C to 232°C).

The Critical Role of Fillers

Base PTFE is often blended with fillers to enhance its mechanical properties for high-pressure use. Fillers like carbon-graphite, fiberglass, or stainless steel improve wear resistance, thermal conductivity, and resistance to deformation under load.

Key Performance Advantages

This combination of material and design allows PTFE seals to offer exceptional performance, including tight sealing at pressures over 35 BAR (500 psi) and high surface speeds exceeding 35 m/s. They are also known for their long, maintenance-free service life.

Understanding the Trade-offs and Selection Criteria

Selecting the correct seal requires a holistic view of the application. The optimal lip style depends entirely on the operational demands and environmental factors.

Balancing Sealing Force and Friction

There is a direct trade-off between aggressive sealing and operational friction. A scraper lip provides a very tight seal but can generate more heat and wear, especially at high speeds.

A tapered lip minimizes friction and wear but may be less effective at containing highly viscous fluids or blocking abrasive external media compared to a scraper design.

Application Parameters are Non-Negotiable

The performance of any seal is dictated by its environment. Critical factors that must be considered include:

- System Pressure: Ensures the seal material and design can withstand the forces.

- Shaft Speed: Determines the need for low-friction designs like the tapered lip.

- Operating Temperature: Must be within the seal material's range.

- Media Being Sealed: Chemical compatibility is essential for seal longevity.

Making the Right Choice for Your Application

Your final selection should be a direct response to the primary challenge of your system.

- If your primary focus is preventing external contamination or sealing in abrasive media: A traditional scraper lip provides the most robust barrier.

- If your primary focus is minimizing friction and heat in high-speed rotating applications: A tapered lip will deliver superior efficiency and a longer service life.

- If your application involves a unique combination of pressure, speed, and media: A custom-designed profile may be necessary to achieve optimal performance.

Ultimately, matching the seal's design and material composition to the specific demands of your application is the key to ensuring system reliability and longevity.

Summary Table:

| Lip Style | Primary Function | Ideal For | Key Consideration |

|---|---|---|---|

| Scraper Lip | Aggressive contaminant & fluid removal | Dirty/abrasive environments, robust leak prevention | Higher friction and potential wear at high speeds |

| Tapered Lip | Low friction, stable hydrodynamic film | High-speed applications, efficiency, long service life | Less effective with highly viscous fluids or abrasive media |

Need a high-performance PTFE seal for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom seals, liners, and labware. Whether you require a standard scraper or tapered lip design or a fully custom solution for the semiconductor, medical, laboratory, or industrial sectors, we provide expert fabrication from prototypes to high-volume orders.

Let our engineering expertise help you solve your toughest sealing challenges. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability