Nearly every high-performance industry leverages PTFE rod for bearings and bushings. Key sectors include aerospace, automotive, chemical processing, and manufacturing, where its unique properties solve critical engineering challenges that other materials cannot. They rely on PTFE for its exceptional heat resistance, chemical inertness, and extremely low friction.

The widespread adoption of PTFE in critical industries isn't accidental. It stems from its unique ability to solve the core challenges of friction, chemical corrosion, and extreme temperatures simultaneously, making it an indispensable material where operational reliability is non-negotiable.

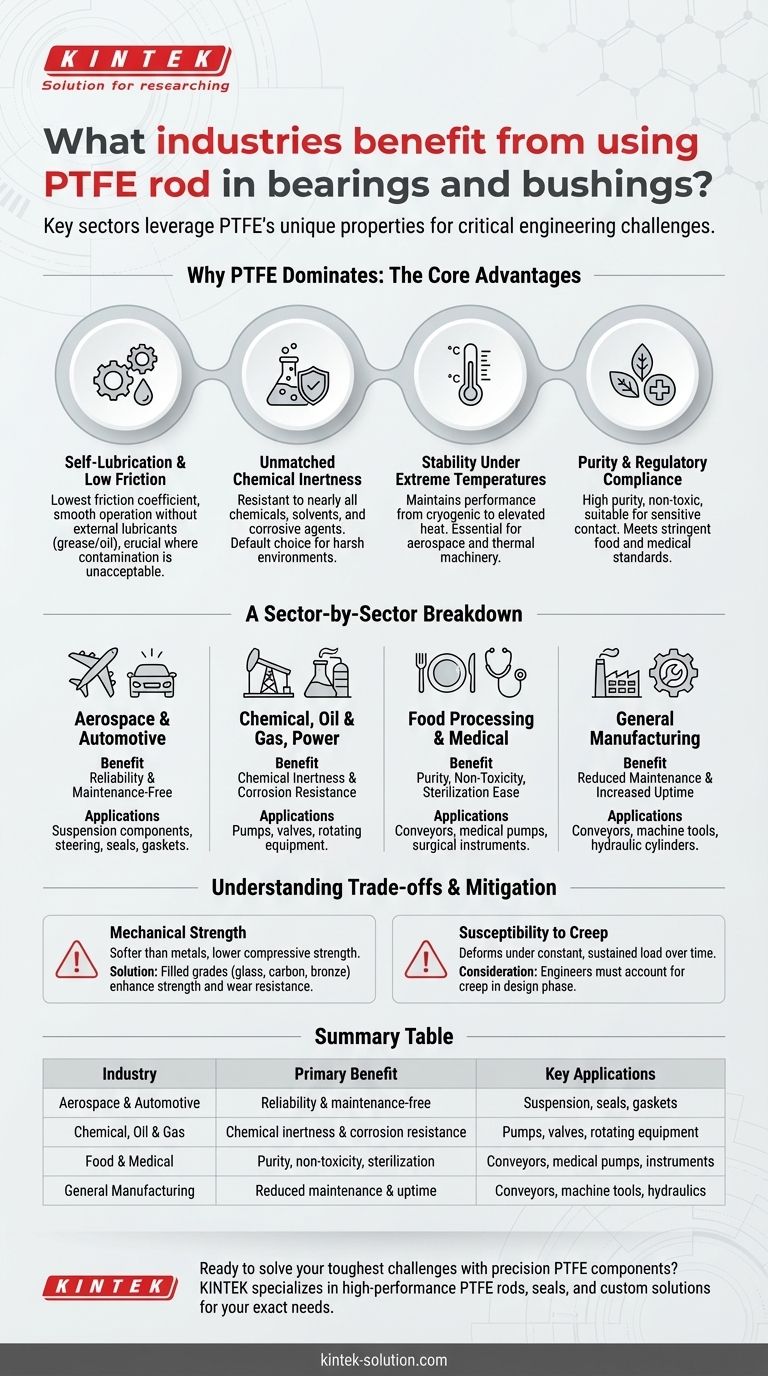

Why PTFE Dominates in Demanding Applications

The value of PTFE (Polytetrafluoroethylene) in bearings and bushings comes from a combination of properties. Understanding these attributes reveals why it is specified for such a diverse range of demanding environments.

The Core Principle: Self-Lubrication and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows for smooth, low-wear operation without the need for external lubricants like grease or oil.

This self-lubricating nature is critical in applications where maintenance is difficult or where contamination from lubricants is unacceptable, such as in food processing or medical equipment.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, solvents, and corrosive agents.

This property makes it the default choice for bearings and bushings in chemical processing plants, oil and gas equipment, and pharmaceutical manufacturing, where components are constantly exposed to harsh substances.

Stability Under Extreme Temperatures

PTFE maintains its integrity and performance across a wide temperature range, from cryogenic conditions to elevated heat.

This thermal stability is essential for aerospace components, automotive parts near engines, and machinery in thermal and nuclear power plants.

Purity and Regulatory Compliance

PTFE can be produced to high purity standards, making it non-toxic and suitable for direct contact with sensitive products.

This is a non-negotiable requirement in the food processing, medical, and pharmaceutical industries, where materials must often meet stringent regulatory approvals.

A Sector-by-Sector Breakdown of PTFE Use

While its core properties are universally beneficial, different industries leverage specific PTFE attributes to solve their unique challenges.

Aerospace and Automotive

In these industries, reliability and performance under stress are paramount. PTFE is used for suspension components, steering columns, seals, and gaskets.

Its low-friction and wear-resistant properties ensure long service life and consistent performance in mechanically intensive systems.

Chemical, Oil & Gas, and Power Generation

These sectors operate in highly corrosive and often high-temperature environments. PTFE bearings are used in pumps, valves, and other rotating equipment.

The material's chemical inertness prevents degradation and equipment failure, ensuring operational safety and continuity.

Food Processing and Medical Devices

Hygiene and non-toxicity are the primary concerns. PTFE is used in food processing conveyors, pumps for medical fluids, and surgical instruments.

Its non-stick, self-lubricating surface resists buildup and can withstand aggressive sterilization and cleaning procedures without degrading.

General Manufacturing and Industrial Machinery

For equipment like conveyors, machine tools, and hydraulic cylinders, the goal is maximizing uptime and minimizing maintenance.

PTFE bushings and bearings reduce service requirements and equipment downtime by eliminating the need for regular lubrication and resisting wear from continuous operation.

Understanding the Trade-offs

Despite its advantages, PTFE is not universally perfect. An objective assessment requires acknowledging its limitations.

Considerations for Mechanical Strength

Compared to metals, virgin PTFE is a relatively soft material with lower compressive strength. In high-load applications, it can be prone to deformation.

To counteract this, PTFE is often blended with fillers like glass, carbon, or bronze to enhance its strength, rigidity, and wear resistance for more demanding mechanical roles.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as "creep."

Engineers must account for this property during the design phase, especially in applications that require maintaining tight tolerances under a persistent load.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to your primary operational goal.

- If your primary focus is reliability in corrosive environments: PTFE's chemical inertness makes it the superior choice for the chemical, oil & gas, and pharmaceutical sectors.

- If your primary focus is maintenance-free operation: The self-lubricating nature of PTFE is ideal for inaccessible components in aerospace, automotive, and industrial machinery.

- If your primary focus is purity and regulatory compliance: PTFE is the default standard for bearings and contact surfaces in food processing and medical device manufacturing.

- If your primary focus is high-load mechanical performance: You must consider filled grades of PTFE or alternative materials, as pure PTFE has limitations in compressive strength.

By understanding these core properties and trade-offs, you can confidently specify PTFE for applications where conventional materials would inevitably fail.

Summary Table:

| Industry | Primary Benefit of PTFE | Key Applications |

|---|---|---|

| Aerospace & Automotive | Reliability & maintenance-free operation | Suspension components, steering columns, seals, gaskets |

| Chemical, Oil & Gas | Chemical inertness & corrosion resistance | Pumps, valves, rotating equipment |

| Food Processing & Medical | Purity, non-toxicity, and ease of sterilization | Conveyors, medical fluid pumps, surgical instruments |

| General Manufacturing | Reduced maintenance & increased uptime | Conveyors, machine tools, hydraulic cylinders |

Ready to solve your toughest friction, chemical, and temperature challenges with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE rods, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact component your application demands.

Contact our experts today to discuss how our PTFE solutions can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs