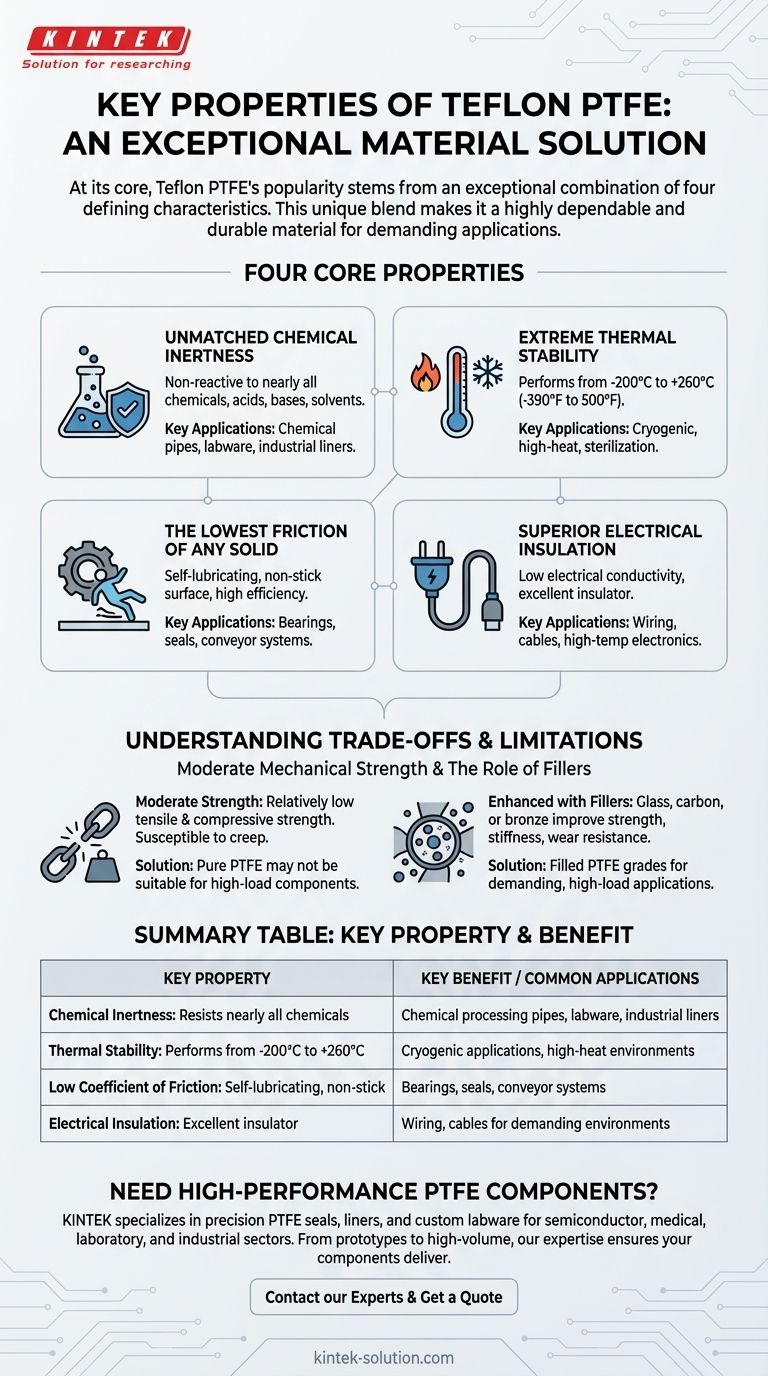

At its core, Teflon PTFE's popularity stems from an exceptional combination of four defining characteristics. This material is renowned for its extreme chemical inertness, its stability across a vast temperature range, its incredibly low coefficient of friction, and its non-stick surface that repels both water and oil. This unique blend makes it a highly dependable and durable material for a wide array of demanding applications.

The defining feature of PTFE is not a single property, but the simultaneous combination of these traits. This synergy makes it a "problem-solver" material for environments where chemical exposure, extreme temperatures, and low-friction movement are all critical concerns.

A Deeper Look at PTFE's Core Properties

To understand why PTFE is so widely used, we must examine how its fundamental properties translate into practical advantages in engineering, laboratory, and industrial settings.

Unmatched Chemical Inertness

The molecular structure of PTFE is the source of its legendary resistance to chemical attack. The polymer chain's carbon backbone is completely sheathed by fluorine atoms, creating a powerful, stable bond.

This structure makes PTFE non-reactive to nearly all chemicals, including aggressive acids, bases, and solvents. In fact, it can only be dissolved by a few select substances like hot fluorine gas or molten alkali metals.

This property is critical for applications like chemical processing pipes, industrial containers, and laboratory equipment where material degradation is not an option.

Extreme Thermal Stability

PTFE maintains its integrity and performance across an exceptionally wide temperature spectrum. It remains stable and functional in conditions ranging from -200°C (-390°F) to over 260°C (500°F).

This allows it to be used reliably in both cryogenic applications and high-heat environments without becoming brittle or melting. Its resistance to steam further enhances its durability in settings requiring sterilization.

The Lowest Friction of Any Solid

PTFE possesses an extremely low coefficient of friction, giving it a slick, slippery surface that few materials can match. This makes it inherently non-stick and self-lubricating.

This characteristic is essential for applications requiring smooth movement, such as in bearings, seals, and conveyor systems. It reduces the power needed to operate machinery, prevents stick-slip behavior in dry-running conditions, and increases overall efficiency.

Superior Electrical Insulation

In addition to its other traits, PTFE exhibits very low electrical conductivity. This property makes it an excellent electrical insulator.

It is frequently used to insulate wiring and cables, particularly in applications where high temperatures or chemical exposure would compromise other insulating materials.

Understanding the Trade-offs and Limitations

While PTFE is an exceptional material, its effectiveness depends on understanding its limitations. Objectivity is key when selecting any material for a critical application.

Moderate Mechanical Strength

PTFE is flexible and does not break easily under typical loads, but its inherent tensile and compressive strength is relatively low compared to engineering plastics or metals. It can be susceptible to creep, which is deformation under a sustained load.

This means that in its pure form, PTFE may not be suitable for high-load structural components.

The Critical Role of Fillers

To overcome its mechanical limitations, PTFE is often enhanced with fillers. Materials like glass, carbon, or bronze can be blended into the PTFE matrix.

These fillers significantly improve properties like compressive strength, stiffness, and wear resistance. This makes filled PTFE grades a common choice for demanding applications like rotary shaft seals, where reliable performance under pressure is essential.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal. Use these points as a guide for deciding if PTFE is the optimal choice for your project.

- If your primary focus is chemical resistance: PTFE is an unparalleled choice for handling aggressive acids, bases, and solvents, especially in labware and industrial linings.

- If your primary focus is low-friction performance: Its self-lubricating and non-stick properties make it ideal for bearings, seals, and coatings requiring smooth, effortless movement.

- If your primary focus is thermal and electrical stability: PTFE provides reliable insulation and structural integrity in both high-temperature and cryogenic electronic applications.

- If your application demands high mechanical wear resistance: Consider a filled grade of PTFE, as its base form has only moderate strength and may not be suitable for high-load scenarios.

Understanding these core properties and their inherent trade-offs is the key to leveraging PTFE's unique capabilities effectively.

Summary Table:

| Key Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals, acids, and solvents | Chemical processing pipes, labware, industrial liners |

| Thermal Stability | Performs from -200°C to +260°C | Cryogenic applications, high-heat environments |

| Low Coefficient of Friction | Self-lubricating, non-stick surface | Bearings, seals, conveyor systems |

| Electrical Insulation | Excellent insulator, even at high temperatures | Wiring, cables for demanding environments |

Need High-Performance PTFE Components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise ensures your components deliver the unmatched chemical resistance, thermal stability, and low friction that your application demands.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers