At their core, PTFE rotary shaft seals reduce maintenance costs by fundamentally altering the dynamics of wear, lubrication, and chemical compatibility in industrial equipment. Their unique material properties lead to significantly longer service intervals, fewer failures, and a drastic reduction in the labor and downtime associated with traditional seal replacement.

The decision to use a PTFE seal is not merely a component choice; it's a strategic shift from a reactive maintenance cycle to a proactive one. By preventing the root causes of seal failure—friction, heat, and chemical attack—they lower the total cost of ownership for the entire system.

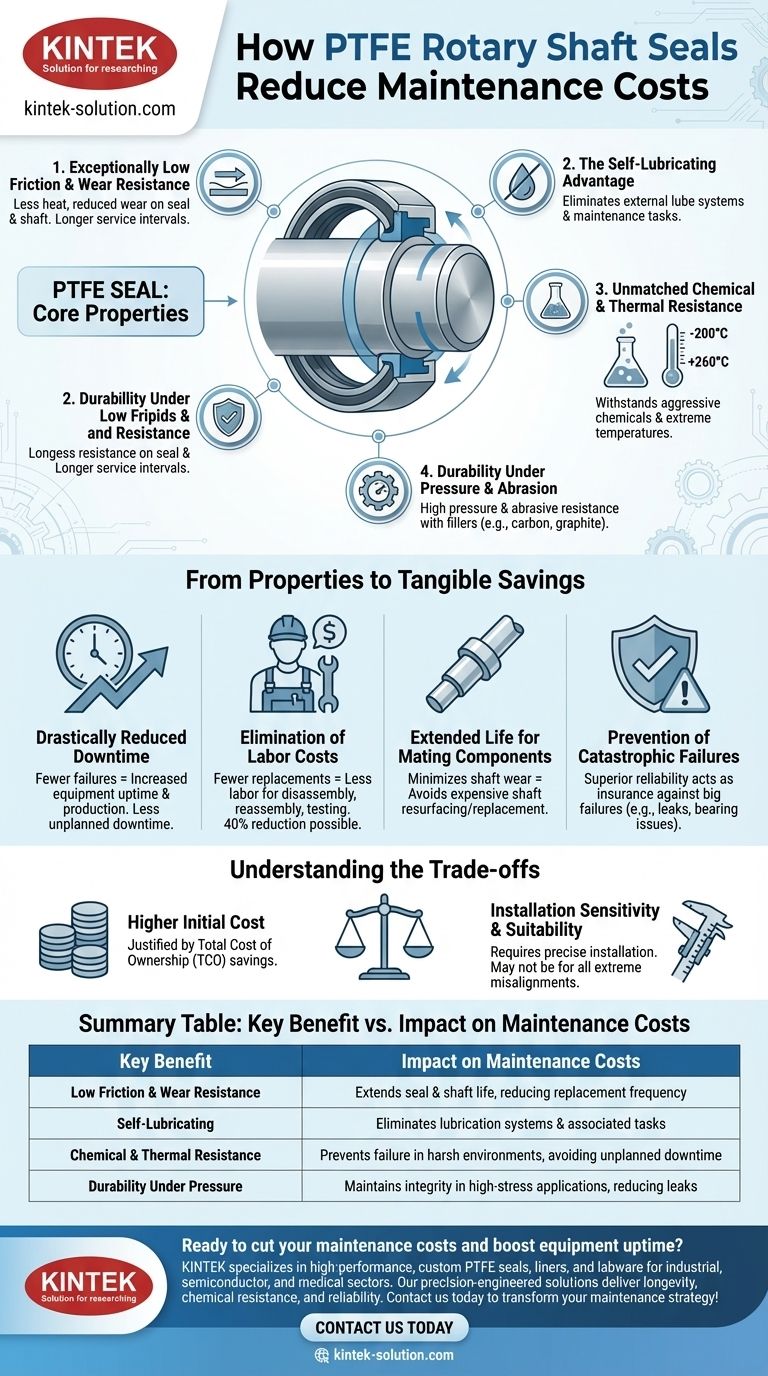

The Core Properties of PTFE That Drive Cost Savings

To understand the financial impact of PTFE seals, you must first understand the material itself. It is not one single benefit but a combination of properties that work together to enhance reliability and reduce maintenance demands.

Exceptionally Low Friction and Wear Resistance

PTFE, known commercially as Teflon®, has one of the lowest coefficients of friction of any solid material. This property is the primary driver of its longevity.

Less friction means less heat generation at the point of contact between the seal and the rotating shaft. This directly reduces wear on both the seal and the shaft, extending the life of both components and preventing costly shaft damage.

The Self-Lubricating Advantage

Unlike many traditional elastomeric (rubber) seals that require a film of oil or grease to function properly, PTFE seals are self-lubricating.

This eliminates the need for external lubrication systems and the associated maintenance tasks of checking levels, refilling reservoirs, and cleaning up leaks. It simplifies machine design and removes a common point of failure.

Unmatched Chemical and Thermal Resistance

PTFE is almost completely chemically inert. It can withstand a vast range of aggressive chemicals, solvents, and corrosive agents that would quickly degrade conventional seals.

Furthermore, it maintains its integrity across an extreme temperature range, from cryogenic lows (-200°C / -328°F) to high heat (+260°C / +500°F). This resilience prevents seal failure in demanding processing environments.

Durability Under Pressure and Abrasion

Modern PTFE seals are often blended with fillers like carbon, graphite, or glass fiber. These compounds enhance the material's strength, allowing it to withstand high pressures and resist abrasive media without significant wear.

This toughness ensures the seal maintains its shape and effectiveness, preventing leaks in high-stress applications and extending its operational lifespan.

How These Properties Translate to Tangible Savings

The material science directly impacts your operational budget. The benefits move from the theoretical to the practical, appearing as clear line items in a maintenance cost analysis.

Drastically Reduced Downtime

The most significant cost in any maintenance event is often the unplanned downtime. Because PTFE seals last significantly longer and fail less frequently, they directly increase equipment uptime and production output.

Elimination of Labor Costs

Consider the labor involved in a typical seal replacement: equipment shutdown, lockout/tagout procedures, disassembly, replacement, reassembly, and testing.

By extending the interval between these events, PTFE seals can cut the associated labor costs by a significant margin. A chemical plant, for instance, reported a 40% reduction in maintenance costs after adopting PTFE components.

Extended Life for Mating Components

The low-friction nature of PTFE doesn't just save the seal; it saves the shaft. By minimizing abrasive wear on the shaft surface, you avoid the expensive and time-consuming process of shaft resurfacing or replacement.

Prevention of Catastrophic Failures

A failed seal can lead to much bigger problems, such as bearing failure from lubricant contamination or hazardous leaks in a chemical plant. The superior reliability of PTFE acts as an insurance policy against these costly and potentially dangerous secondary failures.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective analysis requires acknowledging their specific limitations and considerations.

Higher Initial Cost

PTFE seals typically have a higher upfront purchase price compared to standard nitrile or Viton seals. The cost justification must be based on the total cost of ownership, factoring in the savings from reduced maintenance and downtime over the seal's extended life.

Installation Sensitivity

Proper installation is critical for PTFE seals. Unlike forgiving elastomeric seals, they are less flexible. Any nicks or scratches on the seal or shaft during installation can create a leak path, negating the seal's benefits. Meticulous surface preparation and proper tools are non-negotiable.

Suitability for the Application

While versatile, PTFE may not be the optimal choice for every situation. In applications with extreme shaft runout or dynamic misalignment, a more flexible elastomeric seal might provide a better short-term solution, though it will require more frequent replacement.

Making the Right Choice for Your Operation

The decision to standardize on PTFE seals depends entirely on your specific operational pressures and goals.

- If your primary focus is reducing planned downtime and labor costs: The extended service life of PTFE seals offers the most direct and predictable return on investment.

- If your operation involves aggressive chemicals or extreme temperatures: PTFE is often the only viable choice to ensure seal integrity and prevent hazardous failures.

- If your goal is to increase overall equipment reliability and uptime: The combined benefits of longevity, self-lubrication, and durability make PTFE a powerful upgrade.

Ultimately, adopting PTFE rotary shaft seals is a strategic investment in the long-term health and efficiency of your machinery.

Summary Table:

| Key Benefit | Impact on Maintenance Costs |

|---|---|

| Low Friction & Wear Resistance | Extends seal and shaft life, reducing replacement frequency |

| Self-Lubricating | Eliminates lubrication systems and associated maintenance tasks |

| Chemical & Thermal Resistance | Prevents failure in harsh environments, avoiding unplanned downtime |

| Durability Under Pressure | Maintains integrity in high-stress applications, reducing leaks |

Ready to cut your maintenance costs and boost equipment uptime? At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE rotary shaft seals are designed to deliver the longevity, chemical resistance, and reliability highlighted in this article, directly reducing your total cost of ownership. Whether you need prototypes or high-volume orders, we provide solutions tailored to your unique requirements. Contact us today to discuss how our PTFE seals can transform your maintenance strategy!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications