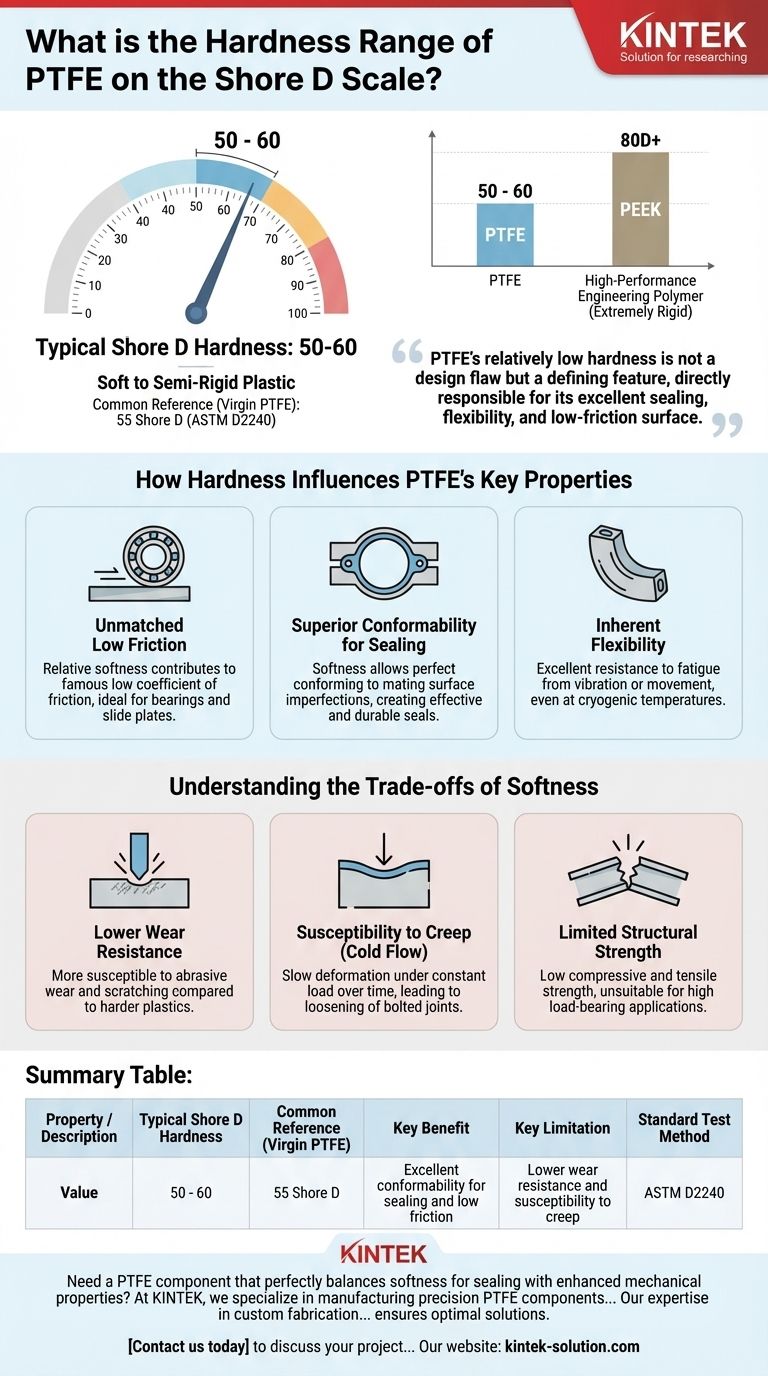

The typical Shore D hardness of PTFE is between 50 and 60. This value places Polytetrafluoroethylene (PTFE) in the category of soft to semi-rigid plastics, making it significantly softer than high-performance engineering polymers like Nylon or PEEK.

PTFE's relatively low hardness is not a design flaw but a defining feature. This softness is directly responsible for its excellent sealing capabilities, flexibility, and unmatched low-friction surface.

What a Shore D 50-60 Hardness Means

Hardness is a measure of a material's resistance to localized indentation. For plastics and polymers, this is commonly measured using a durometer on a Shore scale, with Shore D being used for harder materials.

A Comparative Perspective

A Shore D value of 50-60 means PTFE is firm to the touch but can be flexed or indented with moderate pressure.

To put this in context, a material like PEEK often has a Shore D hardness exceeding 80, making it extremely rigid. PTFE's lower value indicates a more compliant material.

The Role of Standardized Testing

This hardness value is determined using the ASTM D2240 standard test method. A common reference point for virgin (unfilled) PTFE is 55 Shore D, which falls squarely in the middle of the typical range.

How Hardness Influences PTFE's Key Properties

The specific hardness of PTFE is not an isolated number; it is fundamentally linked to the material's most valued performance characteristics.

Unmatched Low Friction

The relative softness of PTFE contributes to its famously low coefficient of friction. The material can deform slightly on a microscopic level, creating an exceptionally smooth, non-stick surface that is ideal for bearings and slide plates.

Superior Conformability for Sealing

For gaskets and seals, hardness is critical. PTFE's softness allows it to conform perfectly to microscopic imperfections on mating surfaces, creating a highly effective and durable seal against liquids and gases.

Inherent Flexibility

Harder plastics can be brittle and prone to stress cracking. PTFE's lower hardness gives it excellent flexibility and resistance to fatigue from vibration or movement, even at cryogenic temperatures.

Understanding the Trade-offs of Softness

While beneficial for many applications, the softness of PTFE introduces limitations that are critical to understand for proper material selection.

Lower Wear Resistance

Compared to harder plastics, virgin PTFE is more susceptible to abrasive wear. Its surface can be scratched or abraded more easily, which can be a limitation in high-load, high-speed dynamic applications.

Susceptibility to Creep (Cold Flow)

Under a constant compressive load, PTFE can slowly deform over time. This phenomenon, known as creep or "cold flow," is more pronounced due to its softness and can lead to the loosening of bolted joints.

Limited Structural Strength

PTFE is not a structural material. Its low hardness corresponds with low compressive and tensile strength, making it unsuitable for applications that require high load-bearing capability. This is why harder, filled grades of PTFE exist to improve these properties.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary demands of your design.

- If your primary focus is sealing, flexibility, or low-friction sliding: The inherent softness (50-60D) of virgin PTFE is precisely what you need for superior conformability and performance.

- If your primary focus is wear resistance or structural integrity: You should consider a harder, filled grade of PTFE (like glass-filled or carbon-filled) or a different, more rigid polymer like PEEK.

Understanding PTFE's hardness is the key to leveraging its unique properties for superior performance in the right application.

Summary Table:

| Property | Value / Description |

|---|---|

| Typical Shore D Hardness | 50 - 60 |

| Common Reference (Virgin PTFE) | 55 Shore D |

| Key Benefit | Excellent conformability for sealing and low friction |

| Key Limitation | Lower wear resistance and susceptibility to creep |

| Standard Test Method | ASTM D2240 |

Need a PTFE component that perfectly balances softness for sealing with enhanced mechanical properties?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the standard conformability of virgin PTFE or a custom-filled grade for improved wear resistance and strength, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the optimal solution for your application.

Contact us today to discuss your project requirements and leverage our material science expertise!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the common grades of PTFE and their applications? Choose the Right Grade for Your Performance Needs

- What are the advantages of PTFE in terms of shelf life and service intervals? Maximize Reliability and Minimize Downtime

- How does PTFE perform when exposed to different types of water? Unmatched Chemical Resistance in Any Aqueous Environment

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What are some trade names for PTFE? Beyond Teflon® to High-Performance Solutions

- What are the mechanical properties of PTFE? Leverage Its Low Friction & Chemical Resistance

- What distinguishes Virgin PTFE from Reprocessed PTFE? Choose the Right Material for Your Application

- What gives PTFE its non-stick properties? The Science Behind Its Slippery Surface