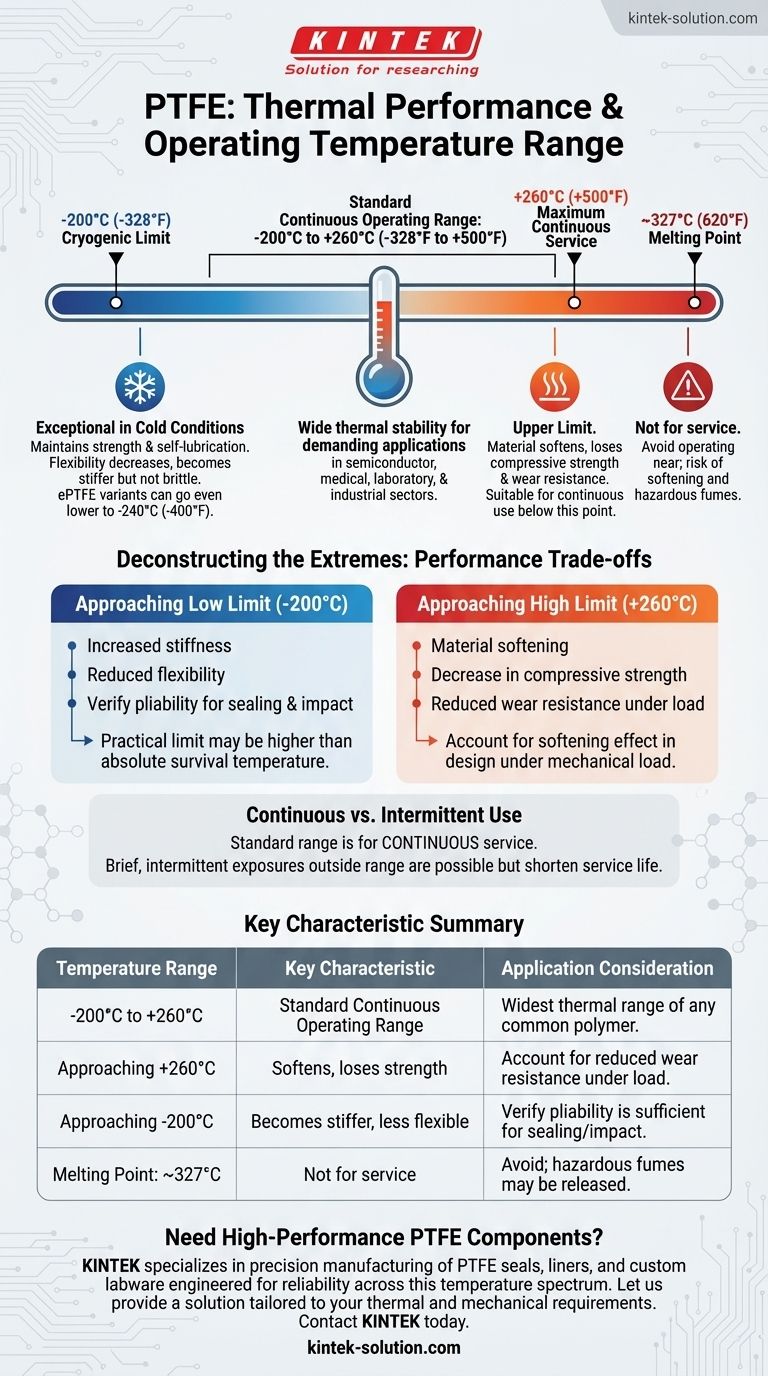

The short answer is that the standard, continuous operating temperature range for PTFE (Polytetrafluoroethylene) is from approximately -200°C to +260°C (-328°F to +500°F). This remarkable thermal stability is a primary reason for its widespread use in demanding applications, far exceeding the limits of most common plastics.

While PTFE has one of the widest temperature ranges of any polymer, its mechanical properties change at the extremes. The key to successful application is not just knowing the absolute limits, but understanding how its performance—particularly flexibility and strength—is affected by the operating temperature.

Deconstructing PTFE's Thermal Performance

To properly assess if PTFE is right for your project, you must look beyond the single temperature range and understand the behavior at both the high and low ends of its spectrum.

The Upper Temperature Limit

The maximum continuous service temperature for PTFE is +260°C (+500°F). Above this point, the material begins to lose its mechanical properties, such as compressive strength and wear resistance, even though it has not yet melted.

The actual melting point of PTFE is significantly higher, around 327°C (620°F). However, operating near this temperature is not recommended, as the material will have softened considerably and may begin to release hazardous fumes. The +260°C limit provides a safe operational ceiling.

The Lower Temperature Limit

PTFE performs exceptionally well in cold conditions. It maintains strength and self-lubrication at cryogenic temperatures as low as -200°C (-328°F) and, in some cases, even lower.

The variance in published low-temperature limits (some sources cite -75°C or -30°C) is due to its flexibility. While PTFE does not become brittle in the way many other plastics do, its flexibility does decrease as temperatures drop. The more conservative numbers reflect applications where maintaining flexibility under stress is critical.

The Impact of PTFE Variants

It is important to recognize that not all PTFE is the same. For example, expanded PTFE (ePTFE) can often handle even lower temperatures, with some grades rated for use down to -240°C (-400°F), while maintaining the same upper limit.

Understanding the Trade-offs at Temperature Extremes

The published temperature range is not a simple "on/off" switch for performance. The material's behavior changes as it approaches these limits.

Approaching the High Limit

As PTFE nears its +260°C (+500°F) ceiling, it becomes softer. This can lead to a decrease in compressive strength and wear resistance. For components under high mechanical load, this softening effect must be accounted for in the design.

Approaching the Low Limit

In cryogenic conditions, PTFE retains its structural integrity but becomes stiffer. For applications requiring a seal to remain pliable or a part to withstand significant impact, the practical low-temperature limit may be higher than its absolute survival temperature.

Continuous vs. Intermittent Use

The standard operating range is intended for continuous service. PTFE can often withstand brief, intermittent exposure to temperatures slightly outside this window without catastrophic failure, but this will shorten the material's overall service life.

How to Apply This to Your Project

Your specific goal will determine which part of PTFE's thermal range is most relevant to your decision.

- If your primary focus is high-heat industrial use: Plan for a maximum continuous temperature of +260°C (+500°F) and be sure to account for the material's loss of strength at the upper end of its range.

- If your primary focus is cryogenic or cold-weather applications: PTFE is an excellent choice down to -200°C (-328°F), but you must verify that its reduced flexibility will not compromise your design.

- If your primary focus is general-purpose reliability: PTFE's exceptionally wide operating window provides a robust safety margin for applications that experience fluctuating environmental temperatures.

Ultimately, leveraging PTFE's thermal stability requires matching its well-defined properties to the specific demands of your environment.

Summary Table:

| Temperature Range | Key Characteristic | Application Consideration |

|---|---|---|

| -200°C to +260°C (-328°F to +500°F) |

Standard Continuous Operating Range | Widest thermal range of any common polymer. |

| Approaching +260°C | Softens, loses strength | Account for reduced wear resistance under load. |

| Approaching -200°C | Becomes stiffer, less flexible | Verify pliability is sufficient for sealing/impact. |

| Melting Point: ~327°C | Not for service | Avoid; hazardous fumes may be released. |

Need High-Performance PTFE Components for Your Application?

PTFE's remarkable thermal stability from -200°C to +260°C makes it ideal for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—that are engineered to perform reliably across this entire temperature spectrum. We prioritize material science and precise production to ensure your components meet exact specifications, from prototypes to high-volume orders.

Let us provide a solution tailored to your thermal and mechanical requirements.

Contact KINTEK today to discuss your project and receive expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is injection molding not suitable for PTFE? The Science Behind Its Incompatibility

- How is PTFE used in the medical field? Discover the Key to Biocompatible Medical Devices

- What makes Teflon suitable for electret manufacturing? Achieve Unmatched Charge Stability for Your Devices

- What specialized testing was performed after accelerated corrosion treatments? Quantify Material Degradation for Safety

- What are the advantages of PTFE's impact resistance? Ensure Unmatched Durability in Harsh Environments

- What are the uses of PTFE in the automotive industry? Ensuring Reliability in Extreme Conditions

- What are the non-toxic properties of PTFE? Ensure Safety in Medical, Food, and Industrial Applications

- What makes PTFE unique compared to other engineering plastics? Unmatched Chemical & Thermal Resistance