Key physical properties of Polytetrafluoroethylene (PTFE) include a high melting point around 327°C, an extremely low dynamic coefficient of friction of approximately 0.04, and a wide continuous service temperature range from -200°C to +260°C. Electrically, it possesses a high dielectric strength of 19.7 kV/mm and a low dielectric constant of 2.0, making it an exceptional insulator.

Your core problem isn't just finding a list of values; it's understanding how PTFE's unique combination of thermal stability, chemical inertness, and low-friction surface properties translates into performance for demanding applications. PTFE is rarely chosen for its mechanical strength, but rather for its ability to survive environments where other materials fail.

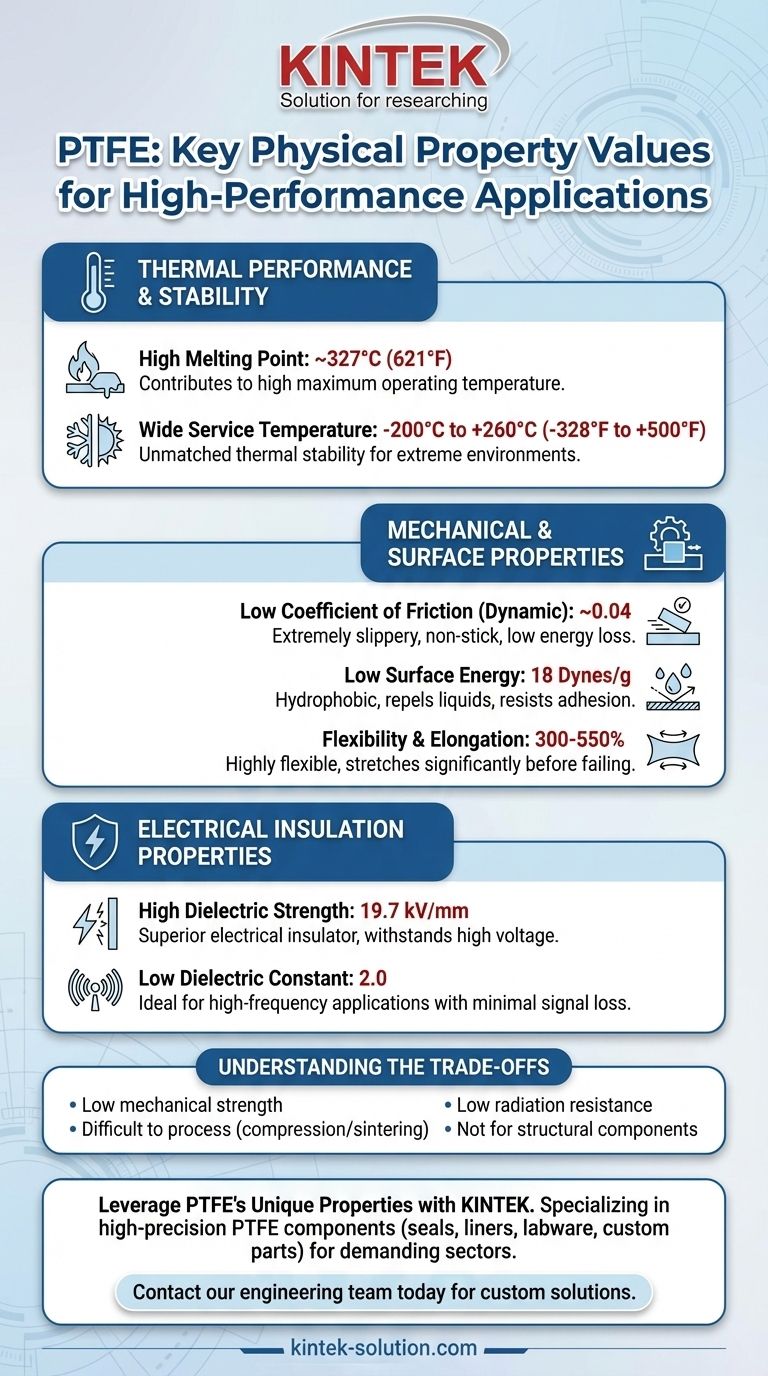

Thermal Performance and Stability

PTFE is defined by its ability to perform reliably across an exceptionally broad temperature spectrum. This makes it a go-to material for both high-heat and cryogenic applications.

High Melting Point

PTFE has a very high melting point for a polymer, typically cited around 327°C (621°F). This contributes to its high maximum operating temperature.

Wide Service Temperature Range

The material maintains its properties over an impressive range, from -200°C (-328°F) to +260°C (+500°F). This stability at both extremes is a critical differentiator from most other plastics.

Mechanical and Surface Properties

The mechanical properties of PTFE are what make it famous as a "non-stick" and "slippery" material. These characteristics stem from its unique molecular structure.

Extremely Low Coefficient of Friction

With a dynamic coefficient of friction around 0.04, PTFE is one of the most slippery solid materials known. This minimizes energy loss in moving parts and prevents other materials from adhering to its surface.

Low Surface Energy

PTFE has a very low surface energy of 18 Dynes/g. This property is the root cause of its non-stick performance and its hydrophobic (water-repelling) nature.

Flexibility and Elongation

While not exceptionally strong, PTFE is highly flexible. It has a tensile modulus of 550 MPa and a high elongation at break between 300-550%, meaning it can stretch significantly before failing.

Electrical Insulation Properties

PTFE is one of the best electrical insulating materials available, especially for high-frequency applications where signal integrity is critical.

High Dielectric Strength

Its dielectric strength is 19.7 kV/mm. This value indicates its ability to withstand a very high voltage before electrical breakdown occurs, making it a superior insulator.

Low Dielectric Constant

PTFE has a low dielectric constant of 2.0. This is extremely important in high-frequency electronics (like coaxial cables) because it minimizes the amount of electrical energy stored in the material, reducing signal loss.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the right choice for every scenario. Understanding its limitations is key to successful application.

Low Mechanical Strength

Compared to engineering plastics like PEEK or even nylon, PTFE is mechanically weak. It has low tensile strength and can be prone to "creep" or deforming under a sustained load. It is not suitable for structural components.

Difficult to Process

Because of its extremely high viscosity when melted, PTFE cannot be processed using conventional melt techniques like injection molding. It must be compressed and sintered—a slower and more costly process.

Low Radiation Resistance

PTFE can be degraded by high-energy radiation, such as gamma or electron-beam radiation. This can break down the polymer's molecular chains, compromising its mechanical properties.

Is PTFE the Right Material for Your Application?

Your choice should be driven by the most critical demand of your project.

- If your primary focus is a low-friction or non-stick surface: PTFE is an unparalleled choice for applications like bearings, seals, and non-stick coatings.

- If your primary focus is high-frequency electrical insulation: Its combination of low dielectric constant and high dielectric strength makes it ideal for coaxial cables, connectors, and printed circuit boards.

- If your primary focus is extreme chemical or temperature resistance: PTFE's chemical inertness and wide service temperature range make it perfect for gaskets, linings, and tubing in harsh environments.

- If your primary focus is high mechanical strength or wear resistance: You should consider filled grades of PTFE (like glass or carbon-filled) or explore alternative high-performance polymers.

Ultimately, PTFE is a specialty material that solves extreme engineering challenges related to temperature, chemicals, and surface friction.

Summary Table:

| Property | Key Value | Significance for Your Application |

|---|---|---|

| Continuous Service Temperature | -200°C to +260°C | Unmatched thermal stability for extreme environments. |

| Dynamic Coefficient of Friction | ~0.04 | Extremely low friction for non-stick, low-wear parts. |

| Dielectric Strength | 19.7 kV/mm | Superior electrical insulation, even under high voltage. |

| Dielectric Constant | 2.0 | Ideal for high-frequency electronics with minimal signal loss. |

| Melting Point | ~327°C | High-temperature resistance for demanding thermal processes. |

Leverage PTFE's Unique Properties for Your Most Demanding Components

Understanding PTFE's physical properties is the first step. The next is partnering with a manufacturer who can precisely fabricate components that leverage these properties to solve your specific challenges.

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to ensure your components deliver on PTFE's promise of extreme thermal stability, chemical inertness, and low friction.

Whether you need a custom prototype or high-volume production, our expertise ensures your application performs reliably.

Ready to design a solution with PTFE? Contact our engineering team today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions