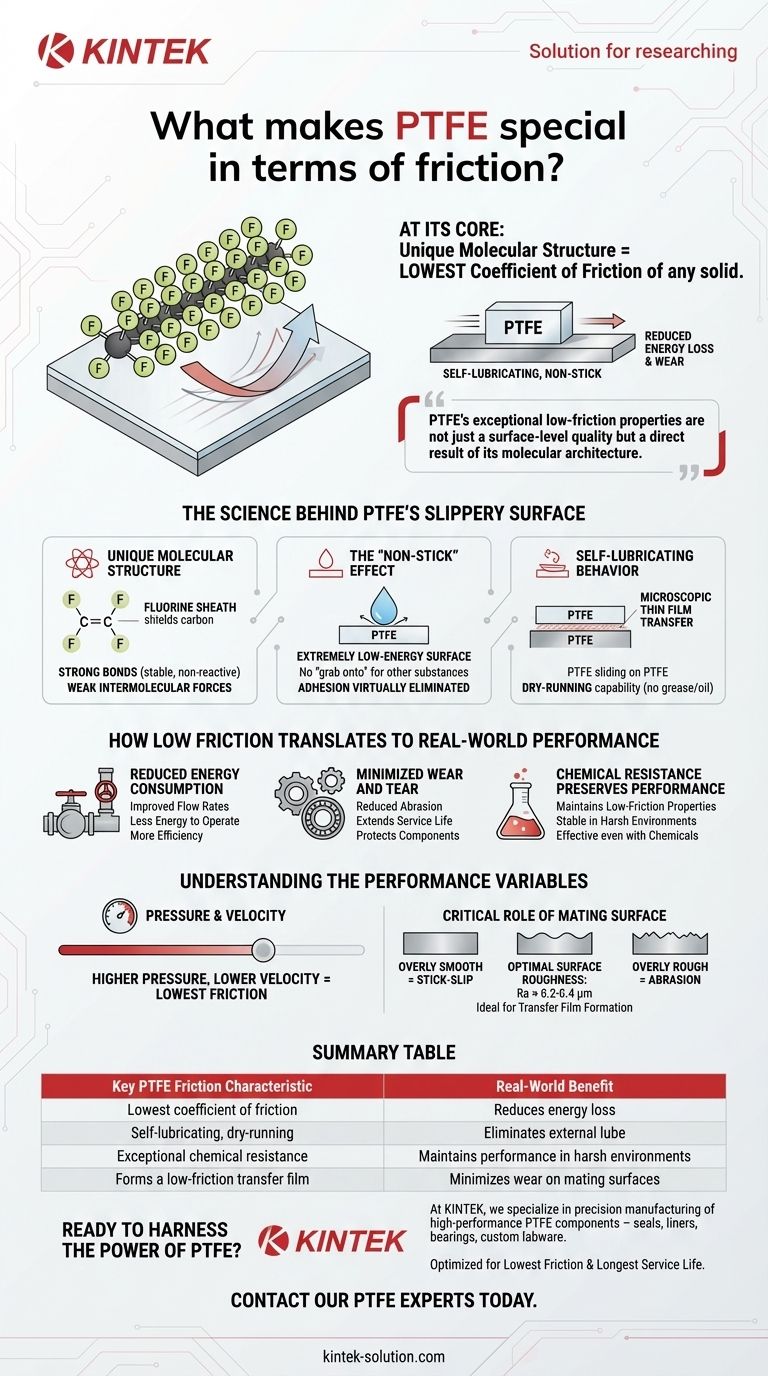

At its core, Polytetrafluoroethylene (PTFE) is special because its unique molecular structure gives it the lowest coefficient of friction of any known solid material. This allows it to function as a self-lubricating, non-stick surface that drastically reduces energy loss and wear in mechanical systems, often without needing any external lubrication.

The key takeaway is that PTFE's exceptional low-friction properties are not just a surface-level quality but a direct result of its molecular architecture. This creates a "slippery" and chemically inert material, but its performance is highly dependent on operational factors like pressure, velocity, and the texture of the mating surface.

The Science Behind PTFE's Slippery Surface

The remarkable friction characteristics of PTFE are not accidental; they are a direct consequence of its specific chemical makeup and the forces at play on a microscopic level.

A Unique Molecular Structure

PTFE consists of a long chain of carbon atoms completely shielded by a helix of larger fluorine atoms. This fluorine sheath effectively protects the carbon backbone from interacting with other surfaces.

The bonds between fluorine and carbon are incredibly strong, making the molecule stable and non-reactive. However, the forces between one sheathed PTFE molecule and another (or any other material) are exceptionally weak.

The "Non-Stick" Effect

This molecular shielding creates an extremely low-energy surface. Other substances have little to nothing to "grab onto," which is why materials do not stick to PTFE.

This "non-stick" quality is fundamental to its low friction. Resistance is minimized because adhesion—one of the primary components of friction—is virtually eliminated at the molecular level.

Self-Lubricating Behavior

A key differentiator for PTFE is its ability to perform in dry-running conditions. Unlike elastomers or metal bearings that require grease or oil, PTFE provides its own lubricity.

When PTFE slides against another surface, a microscopic, thin film of the material transfers to the mating surface. The system then effectively becomes PTFE sliding on PTFE, which results in its famously low friction coefficient.

How Low Friction Translates to Real-World Performance

The theoretical properties of PTFE deliver tangible benefits in demanding engineering applications, from industrial processing to high-performance components.

Reduced Energy Consumption

In systems like valves or pumps, friction directly translates to energy loss. By minimizing this resistance, PTFE-lined components improve flow rates and require less energy to operate.

This allows more material to be processed per cycle, directly improving the efficiency and cost-effectiveness of an industrial operation.

Minimized Wear and Tear

The smooth, low-friction surface of PTFE significantly reduces abrasion on both itself and the components it touches.

This is critical in applications like bearings, seals, and gaskets. Using PTFE can dramatically extend the service life of an entire assembly by protecting parts from friction-related damage.

Chemical Resistance Preserves Performance

PTFE's robust chemical resistance means its low-friction properties are maintained even when exposed to harsh industrial chemicals, liquids, and gases.

Other materials might degrade or swell, altering their surface and increasing friction, but PTFE remains stable and effective.

Understanding the Performance Variables

Achieving the lowest possible friction with PTFE is not automatic. Its performance is a function of the system it's placed in. Understanding these variables is critical for successful design.

The Influence of Pressure and Velocity

The coefficient of friction in PTFE is not a static number. It changes based on operating conditions.

Generally, higher pressure and lower sliding velocities tend to produce the lowest friction values. This makes it ideal for high-load, slow-moving applications.

The Critical Role of the Mating Surface

The surface finish of the material sliding against the PTFE is perhaps the most critical factor for optimal performance.

An overly smooth surface (with a low roughness value) can lead to a "stick-slip" phenomenon, where the surfaces adhere and release, causing jerky motion. Conversely, an overly rough surface will act like sandpaper, accelerating wear and increasing friction.

For the best results, a moderately polished metal surface with a roughness (Ra) of approximately 0.2 to 0.4 micrometers is ideal. This provides just enough texture for the transfer film to form without causing excessive abrasion.

How to Best Leverage PTFE for Your Application

To harness the full potential of PTFE, you must align its properties with your primary engineering goal.

- If your primary focus is maximum efficiency and low energy loss: Use PTFE in components like valve linings and bearings where its low friction directly translates to better flow rates and reduced power consumption.

- If your primary focus is simplified design and maintenance: Choose PTFE for dry-running seals and sliding plates to eliminate the cost and complexity of external lubrication systems.

- If your primary focus is predictable, long-term performance: Pay close attention to the mating surface finish, ensuring it is engineered to the optimal roughness (Ra ≈ 0.2-0.4 µm) to achieve a stable, low-friction transfer film.

Understanding these principles allows you to move beyond simply choosing PTFE and start designing systems that truly capitalize on its unique capabilities.

Summary Table:

| Key PTFE Friction Characteristic | Real-World Benefit |

|---|---|

| Lowest coefficient of friction of any solid | Reduces energy loss in mechanical systems |

| Self-lubricating, dry-running capability | Eliminates need for external grease or oil |

| Exceptional chemical resistance | Maintains performance in harsh environments |

| Forms a low-friction transfer film | Minimizes wear on mating surfaces |

Ready to harness the power of PTFE for your application?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components—including seals, liners, bearings, and custom labware. Our expertise ensures your components are optimized for the lowest friction and longest service life, whether you're in the semiconductor, medical, laboratory, or industrial sector.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific pressure, velocity, and surface finish requirements.

Contact our PTFE experts today to discuss how our components can improve your system's efficiency and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts