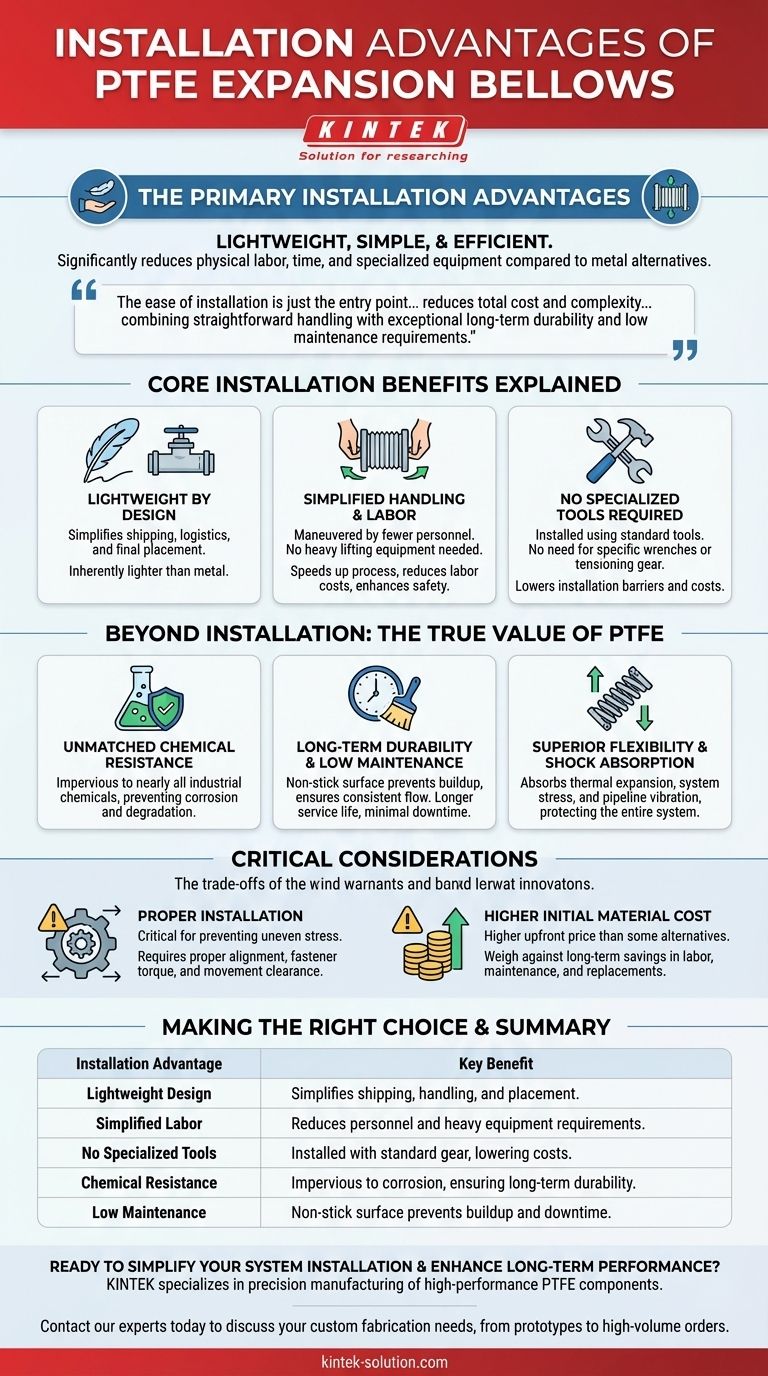

The primary installation advantages of PTFE expansion bellows are their lightweight nature and simplicity. This design significantly reduces the physical labor, time, and specialized equipment required for installation compared to heavier metal alternatives, making them a highly efficient choice from the outset.

The ease of installation is just the entry point to a much larger benefit: PTFE bellows reduce the total cost and complexity of system ownership by combining straightforward handling with exceptional long-term durability and low maintenance requirements.

The Core Installation Benefits Explained

While many components can perform a similar function, the installation process for PTFE bellows presents a clear set of advantages that impact project timelines and budgets directly.

Lightweight by Design

PTFE is inherently much lighter than the metals used in traditional expansion joints. This fundamental difference simplifies every stage of the process, from shipping and logistics to final placement within the pipeline.

Simplified Handling and Labor

The reduced weight means that PTFE bellows can often be maneuvered and installed by fewer personnel without the need for heavy lifting equipment. This not only speeds up the installation process but also reduces direct labor costs and enhances on-site safety.

No Specialized Tools Required

Unlike many heavy-duty metal joints that may require specific wrenches or tensioning equipment, PTFE bellows can typically be installed using standard tools. This accessibility lowers the barrier for installation teams and avoids the cost associated with procuring or renting specialized gear.

Beyond Installation: The True Value of PTFE

The installation benefits are compelling, but they are part of a broader value proposition. The material properties of PTFE are what make these bellows a strategic choice for demanding applications.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials available. This makes it impervious to nearly all industrial chemicals, preventing the corrosion and degradation that can plague metal components and lead to premature failure.

Long-Term Durability and Low Maintenance

The non-stick surface of PTFE prevents material buildup, ensuring consistent fluid flow and eliminating the need for frequent cleaning. This property, combined with its resistance to wear, results in a significantly longer service life and minimal maintenance downtime.

Superior Flexibility and Shock Absorption

PTFE bellows are highly flexible, allowing them to effectively absorb thermal expansion, system stress, and pipeline vibration. This capability protects the entire system from mechanical stresses that could otherwise lead to leaks or catastrophic failure.

Understanding the Trade-offs and Critical Considerations

While PTFE offers significant advantages, a complete understanding requires acknowledging its limitations and the importance of proper procedure.

The Importance of Proper Installation

Though the process is simpler, it is not foolproof. Proper alignment with the pipeline is critical to prevent uneven stress. Adhering to the manufacturer's specified fastener torque and ensuring adequate clearance for movement are essential to avoid premature wear and failure.

Higher Initial Material Cost

Objectively, PTFE expansion bellows often have a higher upfront purchase price than some traditional alternatives. This cost should be weighed against the significant long-term savings from reduced installation labor, minimal maintenance, and fewer replacements over the system's lifespan.

Making the Right Choice for Your System

Selecting the right expansion bellow depends on balancing upfront costs with long-term operational goals.

- If your primary focus is minimizing installation time and labor costs: PTFE bellows are the superior choice due to their lightweight design and simple handling requirements.

- If your primary focus is long-term reliability in corrosive environments: The chemical inertness and durability of PTFE provide a lower total cost of ownership, justifying the initial investment.

- If your primary focus is managing system vibration and thermal movement: The inherent flexibility and shock-absorbing properties of PTFE make it an ideal solution for protecting dynamic piping systems.

Ultimately, choosing PTFE expansion bellows is an investment in your system's operational efficiency and long-term resilience.

Summary Table:

| Installation Advantage | Key Benefit |

|---|---|

| Lightweight Design | Simplifies shipping, handling, and placement. |

| Simplified Labor | Reduces personnel and heavy equipment requirements. |

| No Specialized Tools | Installed with standard gear, lowering costs. |

| Chemical Resistance | Impervious to corrosion, ensuring long-term durability. |

| Low Maintenance | Non-stick surface prevents buildup and downtime. |

Ready to simplify your system installation and enhance long-term performance?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom expansion bellows. Our solutions are designed to reduce your total cost of ownership by combining easy installation with exceptional chemical resistance and durability—perfect for the semiconductor, medical, laboratory, and industrial sectors.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection