The primary benefits of using Polytetrafluoroethylene (PTFE) in seals are its exceptional chemical resistance, a remarkably wide operating temperature range, and an extremely low coefficient of friction. These core properties make PTFE a high-performance solution that offers unmatched durability and reliability in harsh operating conditions where conventional seals would quickly degrade and fail.

PTFE is not merely an alternative sealing material; it is a strategic engineering choice for applications defined by extremes. Its unique combination of properties allows for reliable sealing in environments with aggressive chemicals, high temperatures, and high surface speeds, directly translating to reduced maintenance and enhanced system efficiency.

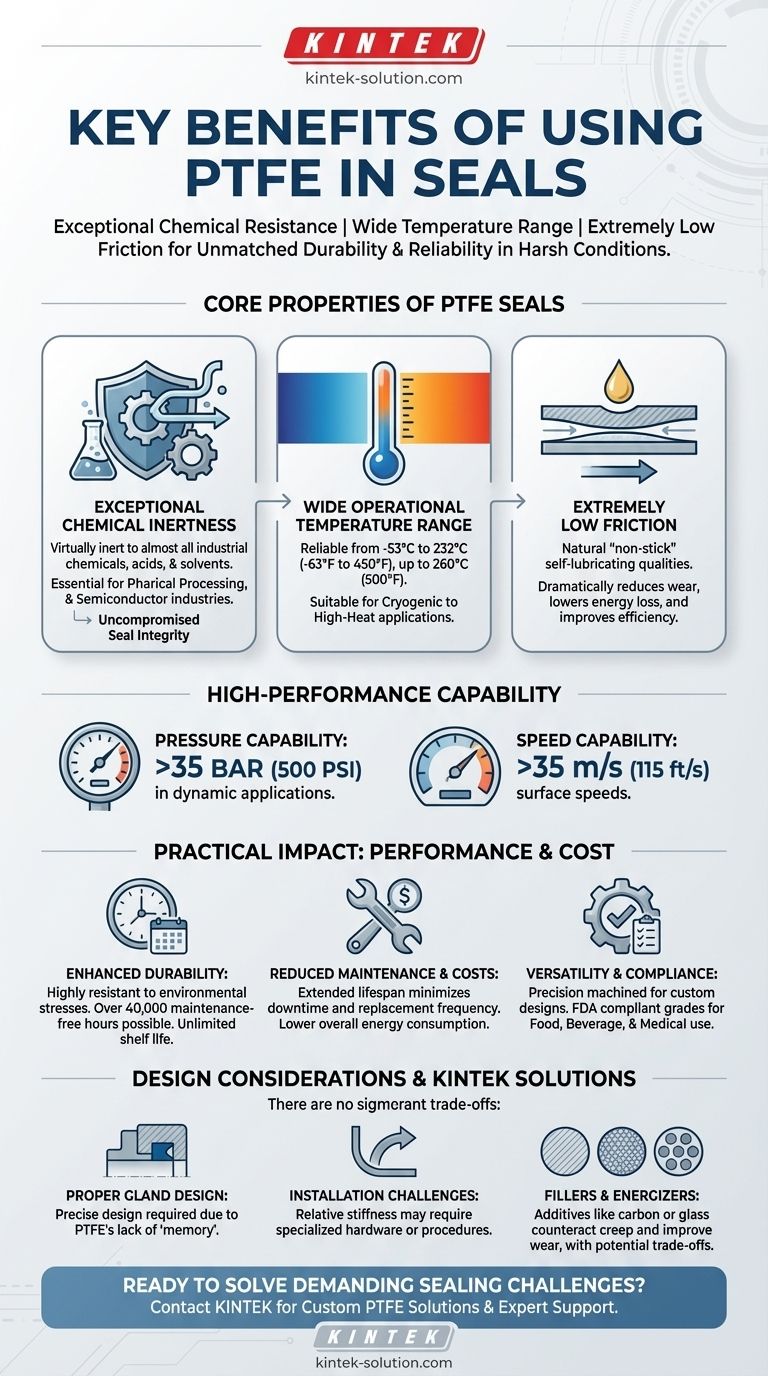

Unpacking the Core Properties of PTFE Seals

The advantages of PTFE stem from its unique molecular structure, which gives it a set of powerful inherent characteristics. Understanding these properties is key to appreciating its value in critical applications.

Exceptional Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential material in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing, where seal integrity cannot be compromised by aggressive media.

Wide Operational Temperature Range

PTFE seals perform reliably across an extreme temperature spectrum, typically from -53°C to 232°C (-63°F to 450°F), with some grades withstanding up to 260°C (500°F). This versatility makes them suitable for everything from cryogenic applications to high-heat automotive and aerospace systems.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it natural "non-stick" or self-lubricating qualities. This dramatically reduces wear and tear on moving parts, improves operational efficiency by lowering energy loss, and allows seals to function effectively even in dry-running or abrasive conditions.

High-Pressure and High-Speed Capability

Engineered PTFE seals are designed for demanding dynamic applications. They can maintain a tight seal at pressures exceeding 35 BAR (500 PSI) and are capable of handling surface speeds of over 35 m/s (115 ft/s), outperforming many standard elastomeric seals in high-performance hydraulic and rotary systems.

The Practical Impact on Performance and Cost

These intrinsic properties translate directly into tangible operational and financial benefits over the lifecycle of the equipment.

Enhanced Durability and Longevity

PTFE is highly resistant to environmental stresses, including moisture and UV radiation. This resilience, combined with its wear resistance, contributes to an exceptionally long service life, with some applications reporting over 40,000 maintenance-free hours. Furthermore, PTFE has an unlimited shelf life, as it does not degrade over time.

Reduced Maintenance and Operating Costs

The extended lifespan and robust nature of PTFE seals directly reduce the frequency of maintenance cycles, downtime, and replacement costs. By minimizing friction and improving efficiency, they also contribute to lower overall energy consumption.

Versatility and Compliance

The ability to machine PTFE into precise, custom-designed parts allows for tailored solutions for specific application needs. Many grades are also FDA compliant, making them safe and suitable for use in food, beverage, and medical equipment.

Understanding the Trade-offs and Design Considerations

While highly effective, successfully implementing PTFE seals requires acknowledging their unique material characteristics during the design phase.

The Importance of Proper Gland Design

PTFE is a plastic, not an elastomer, and lacks the "memory" of rubber. The seal housing, or gland, must be designed precisely to accommodate the material's properties. Incorrect gland design can lead to leakage or bypass, negating the seal's benefits.

Potential Installation Challenges

The relative stiffness of PTFE can make installation difficult, especially in complex machined pockets that require the seal to be twisted or bent. Hardware designs that incorporate features like flanges or retainers can significantly simplify installation and ensure the seal is not damaged.

The Role of Fillers and Energizers

Pure PTFE can be susceptible to creep or cold flow under load. To counteract this and improve wear resistance, fillers like carbon, glass, or bronze are often added. These fillers enhance performance but may slightly reduce the seal's maximum temperature rating or chemical compatibility, creating a trade-off that must be considered.

Making the Right Choice for Your Application

Selecting the right seal is about matching the material's strengths to your primary operational goal.

- If your primary focus is reliability in extreme chemical environments: PTFE's unmatched chemical inertness makes it the definitive choice for handling aggressive fluids that would destroy other materials.

- If your primary focus is high-performance dynamic sealing: PTFE's combination of low friction, high-speed, and high-pressure capabilities is ideal for applications with fast-moving parts, reducing wear and energy loss.

- If your primary focus is reducing long-term maintenance costs: The exceptional durability and long, predictable service life of PTFE seals minimize downtime and replacement frequency in critical systems.

Ultimately, selecting PTFE is an investment in operational resilience for your most demanding sealing challenges.

Summary Table:

| Key Benefit | Key Metric / Description |

|---|---|

| Chemical Resistance | Virtually inert to almost all industrial chemicals, acids, and solvents. |

| Temperature Range | Performs reliably from -53°C to 232°C (-63°F to 450°F), with some grades up to 260°C (500°F). |

| Low Friction | One of the lowest coefficients of friction for reduced wear and energy loss. |

| High-Pressure Capability | Can maintain a tight seal at pressures exceeding 35 BAR (500 PSI). |

| High-Speed Capability | Capable of handling surface speeds of over 35 m/s (115 ft/s). |

| Service Life | Can achieve over 40,000 maintenance-free hours in applications. |

Ready to solve your most demanding sealing challenges with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that delivers:

- Unmatched Reliability: Leverage PTFE's superior properties for longer service life and reduced downtime.

- Custom Fabrication: From prototypes to high-volume orders, we design parts to meet your exact application requirements.

- Expert Support: Our team helps you navigate material selection and gland design for optimal performance.

Invest in operational resilience. Contact KINTEK today for a quote or to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE bars in the chemical industry? Solve Your Toughest Corrosion Problems

- What are the temperature limits for PTFE packing performance? Withstand -200°C to 260°C for Reliable Sealing

- What industries benefit from using PTFE rod in bearings and bushings? Enhance Performance in Demanding Environments

- What is the typical temperature range for PTFE seals? -200°C to 260°C Performance

- What is the temperature range for PTFE O-rings? Withstand Extremes from -200°C to 260°C

- How can PTFE seals be maintained for longevity? Maximize Performance and Lifespan

- What are the advantages and disadvantages of virgin PTFE diaphragms? Achieve Optimal Performance in Critical Applications

- What are the key considerations for PTFE lined butterfly valve installation? Protect Your Liner for a Leak-Proof Seal