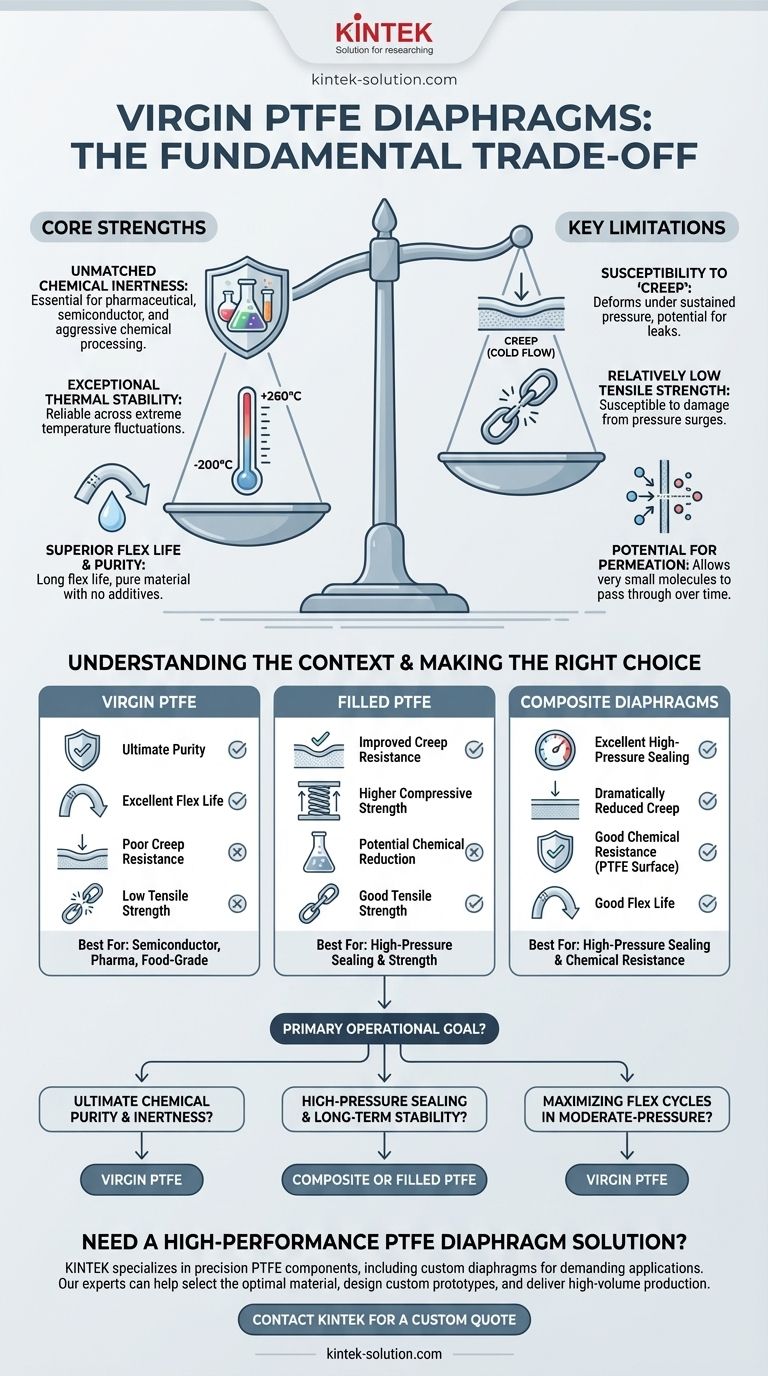

At its core, a virgin PTFE diaphragm is defined by a fundamental trade-off: it offers nearly unparalleled chemical and thermal resistance but comes with significant mechanical limitations. Its primary advantages are its extreme chemical inertness and wide operating temperature range, making it ideal for pure or corrosive environments. However, its primary disadvantages are low tensile strength and a susceptibility to deform under sustained pressure, a phenomenon known as "creep."

The central challenge in selecting a diaphragm is understanding that virgin PTFE is a specialist, not a generalist. It is the definitive choice for applications demanding absolute purity and chemical inertness, but its tendency to deform under load requires careful engineering consideration, especially in high-pressure systems.

The Core Strengths of Virgin PTFE

Virgin Polytetrafluoroethylene (PTFE) is a unique fluoropolymer that provides a combination of properties highly valuable in critical applications.

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, resisting attack from the vast majority of industrial chemicals and solvents. This makes it an essential material in pharmaceutical, semiconductor, and aggressive chemical processing industries.

Its non-contaminating surface ensures that the media passing through the system remains pure.

Exceptional Thermal Stability

This material maintains its properties across an extremely broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability allows it to perform reliably in systems that experience extreme temperature fluctuations without degradation or loss of integrity.

Superior Flex Life and Purity

For dynamic applications like pumps and valves, virgin PTFE diaphragms exhibit a long flex life, enduring millions of cycles without fracturing.

As a pure, unfilled material, it contains no additives or fillers that could leach into the process fluid, guaranteeing the highest level of purity.

Understanding the Trade-offs: Key Limitations

While its strengths are significant, the inherent weaknesses of virgin PTFE are equally critical to understand for proper application.

Susceptibility to "Creep"

The most significant disadvantage of virgin PTFE is its tendency to creep, or "cold flow." When subjected to a constant compressive force, such as the sealing load in a valve, the material will slowly deform over time.

This deformation can lead to a loss of sealing pressure, resulting in leaks and eventual system failure. It is particularly problematic in high-pressure applications.

Relatively Low Tensile Strength

Compared to reinforced or composite materials, virgin PTFE has low tensile strength. This makes it more susceptible to damage from sharp-edged components or high-impact pressure surges.

Careful hardware design is necessary to ensure the diaphragm is not subjected to excessive tensile or tearing forces.

Potential for Permeation

While highly resistant to chemical attack, the molecular structure of pure PTFE can allow very small molecules, like certain gases, to permeate through it over time.

For applications requiring absolute containment of specific gases at high pressure, a composite diaphragm may be a more suitable choice.

How Virgin PTFE Compares to Alternatives

Understanding the context of other materials helps clarify where virgin PTFE fits best.

Versus Filled PTFE

Fillers like glass, carbon, or bronze are added to PTFE to enhance its mechanical properties. Filled PTFE has significantly improved resistance to creep and higher compressive strength.

The trade-off is a potential reduction in chemical resistance, as the filler material may not be as inert as the PTFE itself.

Versus Composite Diaphragms

Composite diaphragms typically bond a thin layer of PTFE to a more robust, flexible backing material like EPDM or Viton rubber.

This construction combines the chemical resistance of PTFE with the strength and memory of rubber, providing excellent high-pressure sealing and dramatically reduced creep.

Making the Right Choice for Your Application

Selecting the correct diaphragm material requires a clear understanding of your primary operational goal.

- If your primary focus is ultimate chemical purity and inertness: Virgin PTFE is the definitive choice for applications in semiconductor, pharmaceutical, or food-grade processing.

- If your primary focus is high-pressure sealing and long-term stability: A composite (PTFE-bonded rubber) or filled PTFE diaphragm will provide better resistance to creep and maintain a more reliable seal.

- If your primary focus is maximizing flex cycles in a moderate-pressure, corrosive environment: Virgin PTFE's excellent flex life makes it a highly durable and cost-effective option.

Choosing the right diaphragm means matching the material's inherent properties to the precise mechanical and chemical demands of your system.

Summary Table:

| Property | Virgin PTFE | Filled PTFE | Composite Diaphragms |

|---|---|---|---|

| Chemical Inertness | Excellent | Good (depends on filler) | Good (PTFE surface) |

| Creep Resistance | Poor | Excellent | Excellent |

| Tensile Strength | Low | High | High |

| Flex Life | Excellent | Good | Good |

| Temperature Range | -200°C to +260°C | Varies | Varies |

| Best For | Ultimate Purity & Chemical Resistance | High-Pressure Sealing & Strength | High-Pressure Sealing & Chemical Resistance |

Need a High-Performance PTFE Diaphragm Solution?

Choosing the right diaphragm material is critical for your system's reliability and purity. The trade-offs between virgin PTFE, filled PTFE, and composite options require expert guidance.

KINTEK specializes in manufacturing precision PTFE components, including custom diaphragms, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand the nuanced balance between chemical resistance, mechanical strength, and long-term stability. Our team can help you:

- Select the optimal material (virgin, filled, or composite) for your specific chemical, pressure, and temperature requirements.

- Design and fabricate custom prototypes to test and validate performance in your system.

- Deliver high-volume production with consistent quality and precision.

Don't let diaphragm failure compromise your process. Contact our experts today to discuss your application and get a solution engineered for peak performance.

Contact KINTEK for a Custom PTFE Diaphragm Quote

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications