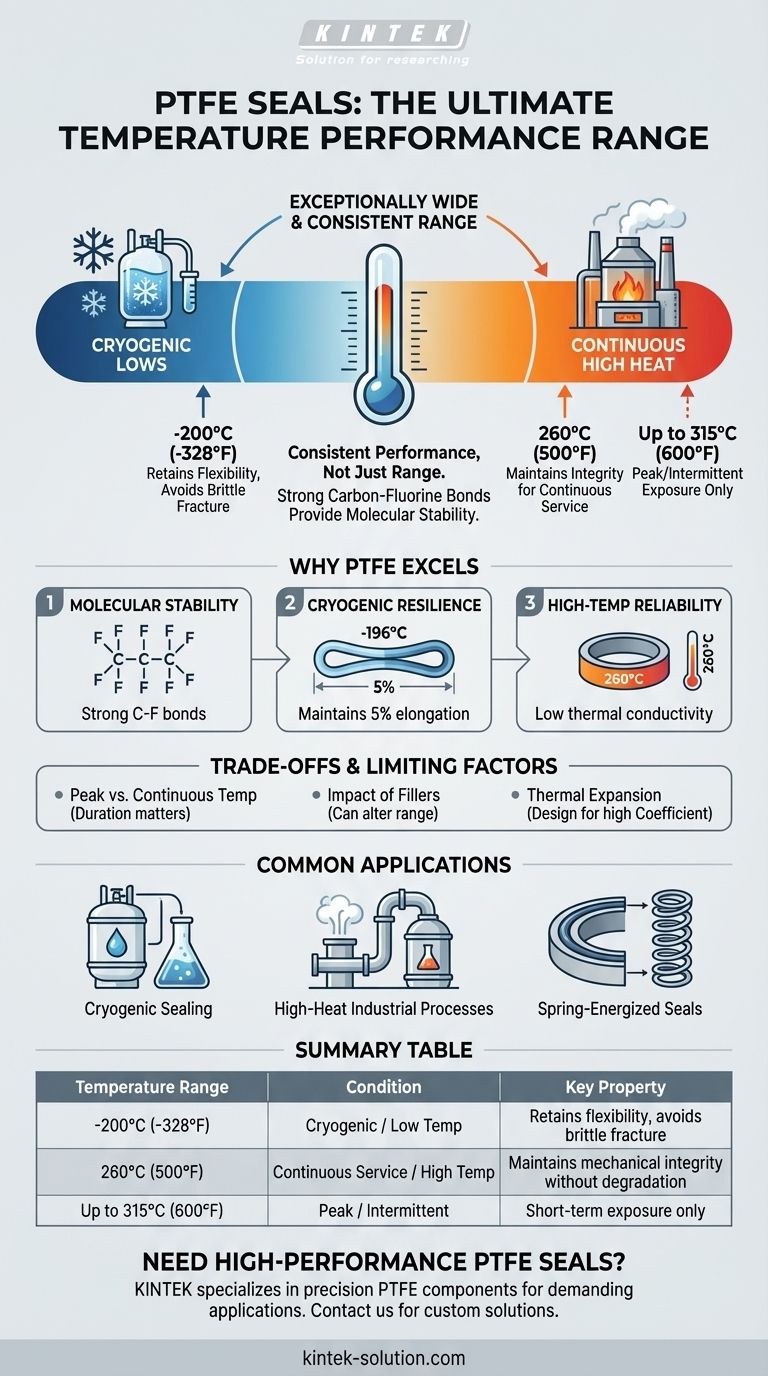

In short, the operational temperature range for virgin PTFE seals is exceptionally wide. The material typically performs reliably from cryogenic lows of approximately -200°C (-328°F) up to continuous high temperatures of 260°C (500°F). This remarkable stability makes it a default choice for sealing applications at the extreme ends of the thermal spectrum.

The core reason for selecting PTFE is not just its wide temperature range, but its consistency across that range. Unlike many polymers that become brittle at low temperatures or degrade rapidly at high temperatures, PTFE maintains its integrity and core sealing properties.

Why PTFE Excels in Extreme Temperatures

The performance of Polytetrafluoroethylene (PTFE) is a direct result of its unique molecular structure. Understanding this provides the context for its wide application in demanding environments.

Stability at the Molecular Level

The foundation of PTFE's thermal stability lies in its strong carbon-fluorine bonds. These are some of the most powerful single bonds in organic chemistry, requiring a significant amount of energy to break. This inherent strength prevents the material from degrading or losing its properties when exposed to thermal energy.

Performance in Cryogenic Conditions

Many materials become extremely brittle and fracture at very low temperatures. PTFE is a notable exception.

It remains functional down to approximately -200°C (-328°F). Critically, it retains a degree of flexibility and ductility, with sources noting it can maintain 5% elongation even at -196°C. This prevents catastrophic failure in applications involving liquid nitrogen or other cryogenic fluids.

Resilience at High Temperatures

PTFE has a high melting point and low thermal conductivity, allowing it to serve as a reliable sealant in high-heat processes.

The widely accepted continuous service temperature is 260°C (500°F). This is the temperature at which the material can operate indefinitely without significant degradation of its mechanical properties.

Understanding the Trade-offs and Limiting Factors

While the temperature range is impressive, a material's suitability is never defined by a single number. Professional-grade applications require a more nuanced understanding.

Continuous vs. Peak Temperature

Some sources may cite higher temperature limits, such as 315°C (600°F). It is critical to understand this as a peak or intermittent temperature, not a continuous one. Exposing a PTFE seal to temperatures above its continuous rating for extended periods will accelerate degradation and lead to seal failure.

The Impact of Fillers

Commercial PTFE seals are often blended with fillers (e.g., glass, carbon, graphite) to improve properties like wear resistance, creep resistance, and dimensional stability. These fillers can sometimes slightly alter the effective temperature range of the compound, and this must be verified with the manufacturer.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. In seal design, this means the gland or housing must be engineered to accommodate the seal's expansion at high temperatures and contraction at low temperatures to maintain a proper sealing force.

Common Applications Driven by Temperature Range

The properties of PTFE make it indispensable in applications where other sealing materials, like common elastomers, would instantly fail.

Cryogenic Sealing

The material's ability to avoid brittle fracture makes it a primary choice for seals in equipment for liquid natural gas (LNG), industrial gases, and scientific or aerospace applications involving cryogenic fluids.

High-Heat Industrial Processes

PTFE seals are frequently used in high-temperature environments that also demand chemical resistance. Common examples include seals for steam lines, chemical processing, petroleum refining, and even components in jet propulsion systems.

Spring-Energized Seals

In this advanced seal design, a PTFE "jacket" provides the temperature and chemical resistance, while an internal metal spring provides a constant energizing force. This combination creates a highly reliable seal that functions effectively across the entire PTFE temperature spectrum.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's properties to your specific operational goals.

- If your primary focus is extreme cold (cryogenics): PTFE is a leading choice because it retains crucial flexibility where other polymers would become brittle and fail.

- If your primary focus is high continuous heat: Standardize on the 260°C (500°F) continuous operating limit and consider filled grades for improved mechanical stability under load.

- If your application involves thermal cycling: You must engineer the seal gland to account for PTFE's significant thermal expansion and contraction to ensure a reliable seal at all temperatures.

Understanding these properties allows you to leverage PTFE's remarkable thermal stability with confidence in your most critical sealing applications.

Summary Table:

| Temperature Range | Condition | Key Property |

|---|---|---|

| -200°C (-328°F) | Cryogenic / Low Temp | Retains flexibility, avoids brittle fracture |

| 260°C (500°F) | Continuous Service / High Temp | Maintains mechanical integrity without degradation |

| Up to 315°C (600°F) | Peak / Intermittent | Short-term exposure only |

Need a PTFE seal that performs reliably from cryogenic to high-heat environments?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get a seal that is perfectly engineered for your specific temperature, chemical, and pressure requirements, from prototypes to high-volume orders.

Contact us today to discuss your application and get a quote for high-performance PTFE seals.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance