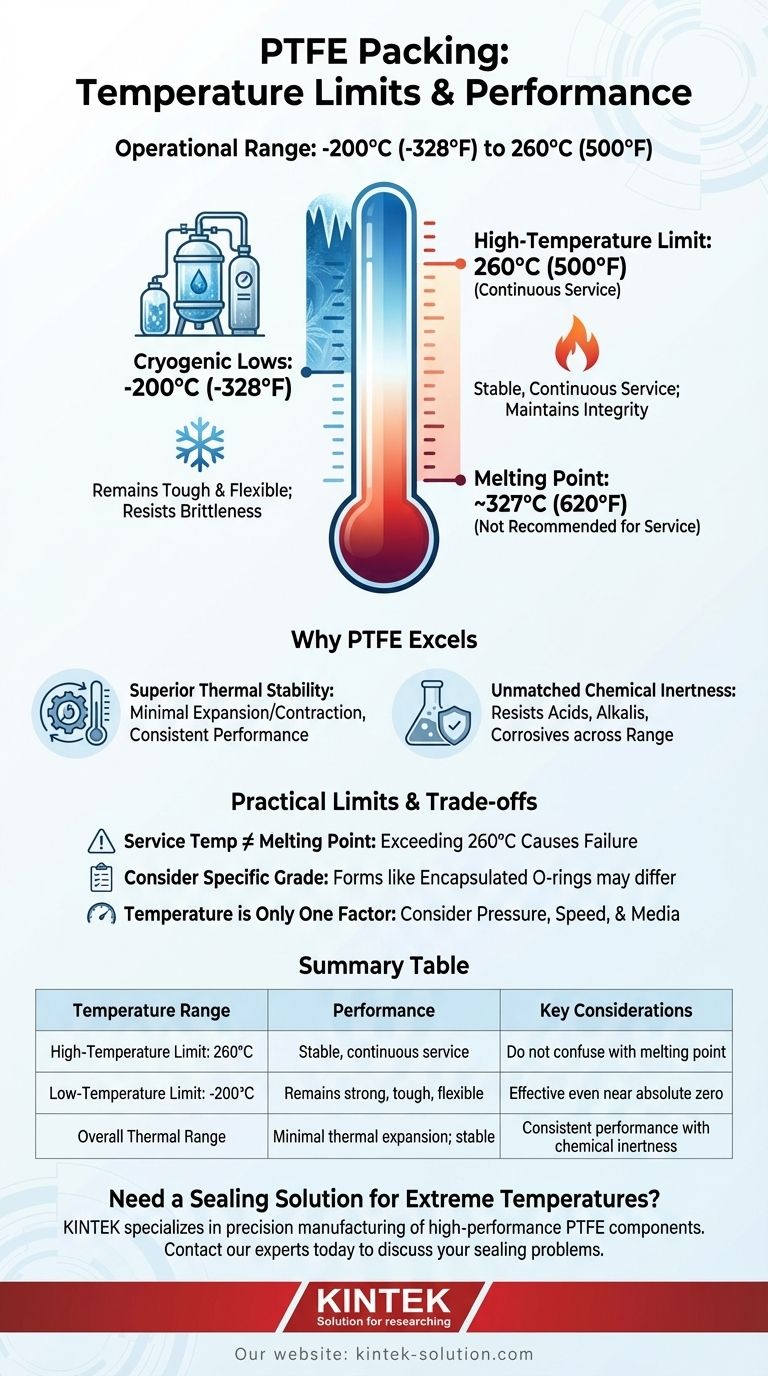

In short, PTFE packing has a remarkably wide operational temperature range, generally accepted to be from -200°C (-328°F) to 260°C (500°F). This stability allows it to function reliably in applications from cryogenic freezing to high-temperature industrial processes, maintaining its structural integrity and sealing performance where other materials would fail.

The central takeaway is that PTFE's value lies not just in its high-temperature tolerance but in its entire thermal range. Its ability to remain strong and flexible at cryogenic lows is just as critical as its stability at high heat, making it one of the most versatile sealing materials available.

Deconstructing the Temperature Range

Understanding the limits at both ends of the spectrum is key to leveraging PTFE's full capabilities. The material behaves predictably and reliably within this broad window.

High-Temperature Performance

PTFE is well-suited for high-temperature applications, with a continuous service limit of 260°C (500°F). This is the maximum temperature at which it can operate for extended periods without significant degradation of its mechanical properties.

It's important to note that PTFE's actual melting point is much higher, around 327°C (620°F). However, operating near this temperature is not recommended as the material will soften and lose its structural integrity long before it melts completely.

Cryogenic and Low-Temperature Resilience

At the low end, PTFE's performance is equally impressive. It maintains high strength, toughness, and flexibility at temperatures as low as -200°C (-328°F).

Some data suggests it retains useful properties down to temperatures approaching absolute zero, maintaining self-lubrication at 5°K (-268°C / -450°F). This prevents it from becoming brittle, a common failure point for other polymers in deep-freeze conditions.

Why PTFE Excels in Extreme Temperatures

PTFE’s wide temperature range is not an accident; it is a direct result of its unique molecular structure and chemical composition. This foundation gives it two key advantages.

Superior Thermal Stability

PTFE exhibits minimal changes due to thermal expansion or contraction. This stability ensures that a seal made from PTFE packing will maintain its dimensions and sealing pressure, even when subjected to significant temperature swings.

This property prevents the loss of structural integrity that can compromise sealing performance in dynamic thermal environments.

Unmatched Chemical Inertness

Temperature resistance is only useful if the material can also withstand the process media. PTFE is famously inert, resisting nearly all industrial acids, alkalis, and corrosive substances.

This chemical resistance is maintained across its entire temperature range, ensuring reliable sealing in harsh chemical environments, whether hot or cold.

Understanding the Practical Limits and Trade-offs

While the numbers are impressive, applying them correctly requires understanding the context and potential limitations. An absolute temperature rating is only part of the full technical picture.

Service Temperature vs. Melting Point

The most common mistake is conflating the maximum service temperature with the melting point. The safe, continuous operating limit for PTFE is 260°C (500°F). Pushing the material beyond this point, even if below the melting point, will cause it to lose its sealing ability and fail prematurely.

Consider the Specific Grade and Form

The general temperature range applies to virgin PTFE, but the exact limits can vary slightly based on the form factor. For example, a PTFE encapsulated O-ring may have a slightly lower rating, such as 205°C (400°F), due to the core material it protects.

Always consult the manufacturer's data sheet for the specific product you are using to confirm its operational limits.

Temperature is Only One Factor

A packing's success depends on a combination of factors, including pressure, shaft speed (in dynamic applications), and the chemical media being sealed. An application with high pressure and high temperature will be more demanding than one with high temperature alone.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE packing meets the demands of your specific operational environment.

- If your primary focus is high-temperature sealing: PTFE is an excellent choice up to its continuous limit of 260°C (500°F), offering a reliable seal without chemical degradation.

- If your primary focus is cryogenic performance: PTFE is a premier choice, as it remains tough and flexible down to -200°C (-328°F) and avoids the brittleness that causes other materials to fail.

- If you are managing a harsh environment with thermal cycling: PTFE's combined resistance to chemicals and its low thermal expansion make it a highly reliable solution for complex and demanding conditions.

Ultimately, PTFE's ability to perform consistently across this vast thermal spectrum makes it a foundational material for solving difficult sealing challenges.

Summary Table:

| Temperature Range | Performance Characteristics | Key Considerations |

|---|---|---|

| High-Temperature Limit: 260°C (500°F) | Stable, continuous service; maintains sealing integrity. | Do not confuse with melting point (327°C). Exceeding 260°C causes softening and failure. |

| Low-Temperature Limit: -200°C (-328°F) | Remains strong, tough, and flexible; resists brittleness. | Effective even in cryogenic applications near absolute zero. |

| Overall Thermal Range | Minimal thermal expansion/contraction; stable performance during thermal cycling. | Performance is consistent across the entire range when combined with chemical inertness. |

Need a Sealing Solution for Extreme Temperatures?

PTFE's unparalleled thermal range from cryogenic lows to high heat, combined with its supreme chemical resistance, makes it the ideal choice for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware. Whether you require a standard part or a custom-fabricated solution from prototype to high-volume production, we are committed to delivering the reliability your critical processes demand.

Contact our experts today to discuss how our PTFE components can solve your most challenging sealing problems.

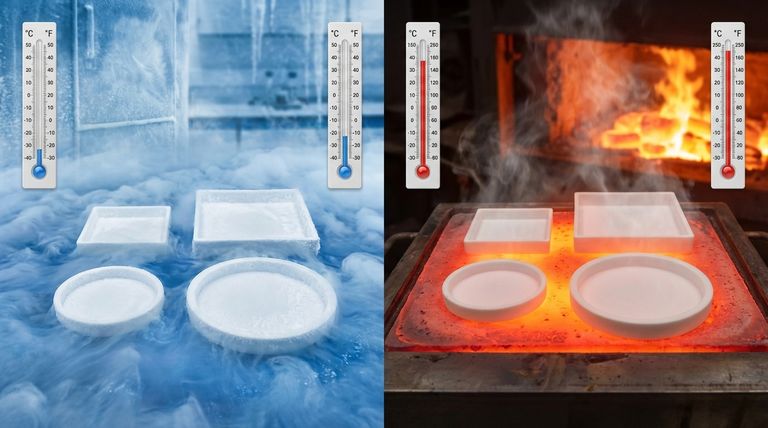

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry