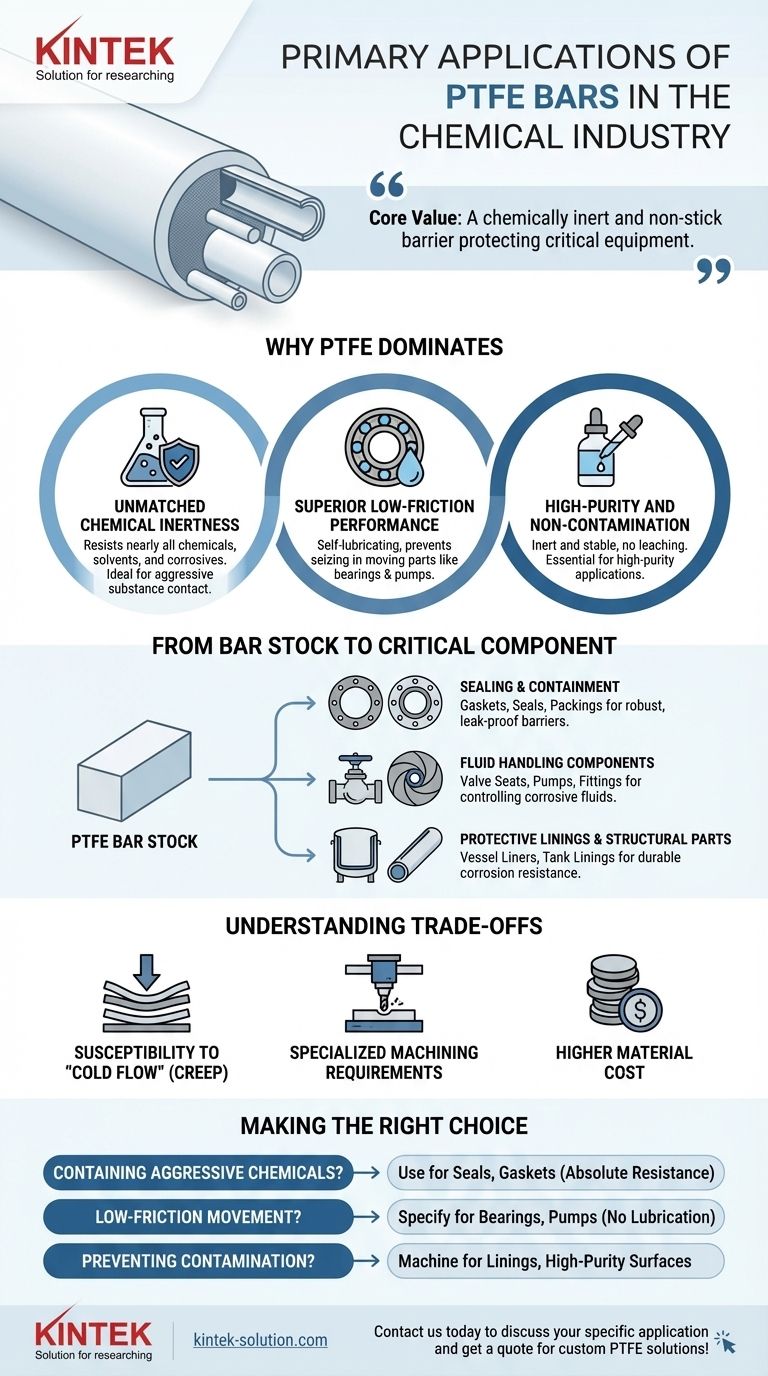

In the chemical industry, Polytetrafluoroethylene (PTFE) bars are primarily machined into critical components that must withstand highly corrosive environments, provide reliable sealing, and offer low-friction performance. These applications range from creating custom gaskets and valve seats to fabricating entire pump bodies and protective vessel linings, leveraging PTFE's unique material properties to ensure operational safety and integrity.

The core value of PTFE bar stock is its ability to be transformed into a chemically inert and non-stick barrier. This protects critical equipment from aggressive media, prevents leaks, and maintains product purity in the most demanding industrial settings.

Why PTFE Dominates in Hostile Chemical Environments

The widespread use of PTFE is not accidental. It stems from a combination of properties that make it uniquely suited for the challenges posed by chemical processing.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, solvents, and corrosive agents. This near-total chemical immunity is its most significant advantage.

This property makes it the material of choice for components in direct contact with aggressive substances, such as linings for reaction vessels, pipes, and tanks.

Superior Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It provides a self-lubricating surface.

This is ideal for dynamic applications where traditional lubricants would fail or contaminate the process, such as in bearings, bushings, and the moving parts of pumps and valves.

High-Purity and Non-Contamination

Because PTFE is so inert and stable, it does not leach chemicals or contaminate the media it contacts.

This makes it indispensable in high-purity applications, including the pharmaceutical, semiconductor, and food and beverage industries, where preventing contamination is paramount.

From Bar Stock to Critical Component: Primary Applications

PTFE bars are a versatile starting point, easily machined into a wide variety of custom parts tailored to specific functions within a chemical plant.

Sealing and Containment: Gaskets, Seals, and Packings

The most common application is creating robust seals. PTFE's ability to resist chemical attack and deformation ensures a long-lasting, leak-proof barrier.

These components are critical in valves, pumps, and pipe flanges to prevent the escape of hazardous or high-pressure fluids, protecting both personnel and equipment.

Fluid Handling Components: Valves, Pumps, and Fittings

Entire components or their critical internal parts are often machined from PTFE bars. This includes valve seats, plugs, impellers, and diaphragms.

Using PTFE ensures that the parts responsible for controlling and moving corrosive fluids will not degrade, seize, or fail prematurely.

Protective Linings and Structural Parts

Larger PTFE bars, often called billets, can be machined to create thick, durable linings for steel reactors, distillation towers, and storage tanks.

In some cases, smaller structural components that require complete corrosion resistance are fabricated entirely from PTFE bar stock.

Understanding the Trade-offs

While exceptionally useful, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively.

Susceptibility to "Cold Flow" or Creep

PTFE is a relatively soft material and can deform or "creep" over time when subjected to a constant load, especially at elevated temperatures. This must be accounted for in the design of gaskets and structural parts.

Specialized Machining Requirements

While machinable, PTFE's softness and thermal properties require specific tools, speeds, and techniques to achieve tight tolerances without causing deformation or poor surface finish.

Higher Material Cost

PTFE is a premium performance polymer, and its cost is significantly higher than that of common plastics or metals. Its use is justified when its unique properties are essential for safety, purity, or equipment longevity.

Making the Right Choice for Your Application

Your final decision should be driven by the primary engineering challenge you need to solve.

- If your primary focus is containing aggressive chemicals: Use PTFE for seals, gaskets, and valve components where absolute chemical resistance is non-negotiable.

- If your primary focus is low-friction movement: Specify PTFE for bearings, bushings, and pump parts that must operate without traditional lubricants in a corrosive environment.

- If your primary focus is preventing product contamination: Machine PTFE bars into linings for vessels and pipes to create a high-purity, non-reactive contact surface.

Understanding these core applications and their underlying principles allows you to leverage PTFE not just as a material, but as a strategic solution for your most demanding chemical processing challenges.

Summary Table:

| Application | Key PTFE Property Utilized | Common Components |

|---|---|---|

| Sealing & Containment | Chemical Inertness | Gaskets, Seals, Packings |

| Fluid Handling | Low Friction & Chemical Resistance | Valve Seats, Pump Impellers |

| Protective Linings | High Purity & Non-Contamination | Vessel Liners, Tank Linings |

Ready to solve your toughest chemical processing challenges with precision-machined PTFE components?

KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your equipment is protected from aggressive chemicals and maintains product purity.

Contact us today to discuss your specific application and get a quote for custom PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What materials are used in the manufacturing of PTFE ball valves? Optimize for Chemical Resistance & Performance

- What medical applications benefit from PTFE's biocompatibility? Ensuring Patient Safety in Critical Devices

- What role does Teflon sheet play in the packaging industry? Ensuring Clean, Non-Stick Heat Sealing

- What design considerations are important for PTFE slide bearing implementation? Achieve Long-Lasting, Low-Friction Performance

- What material are Teflon sheets typically made from? Uncover the Power of PTFE

- What modifications can be made to a PTFE seal to handle slight shaft runout? Compensate for Dynamic Movement

- How is TFE (tetrafluoroethylene) produced? A Guide to the High-Temperature Synthesis Process

- How is lateral movement restricted in PTFE sliding bearings? Guide Plates and Dowel Pins Explained