At its core, maintaining PTFE seals for longevity is not about frequent, active intervention but about protecting the material's inherent properties. The essential practices are regular visual inspections for damage, ensuring cleanliness without harsh chemicals, monitoring operating conditions like temperature and pressure, and replacing seals promptly at the first sign of degradation.

The most critical principle for PTFE seal maintenance is to preserve, not "fix." Unlike other materials that may require lubrication or additives, PTFE's longevity comes from its natural low-friction and inert characteristics. Your primary goal is to protect it from physical damage and contamination that compromise these properties.

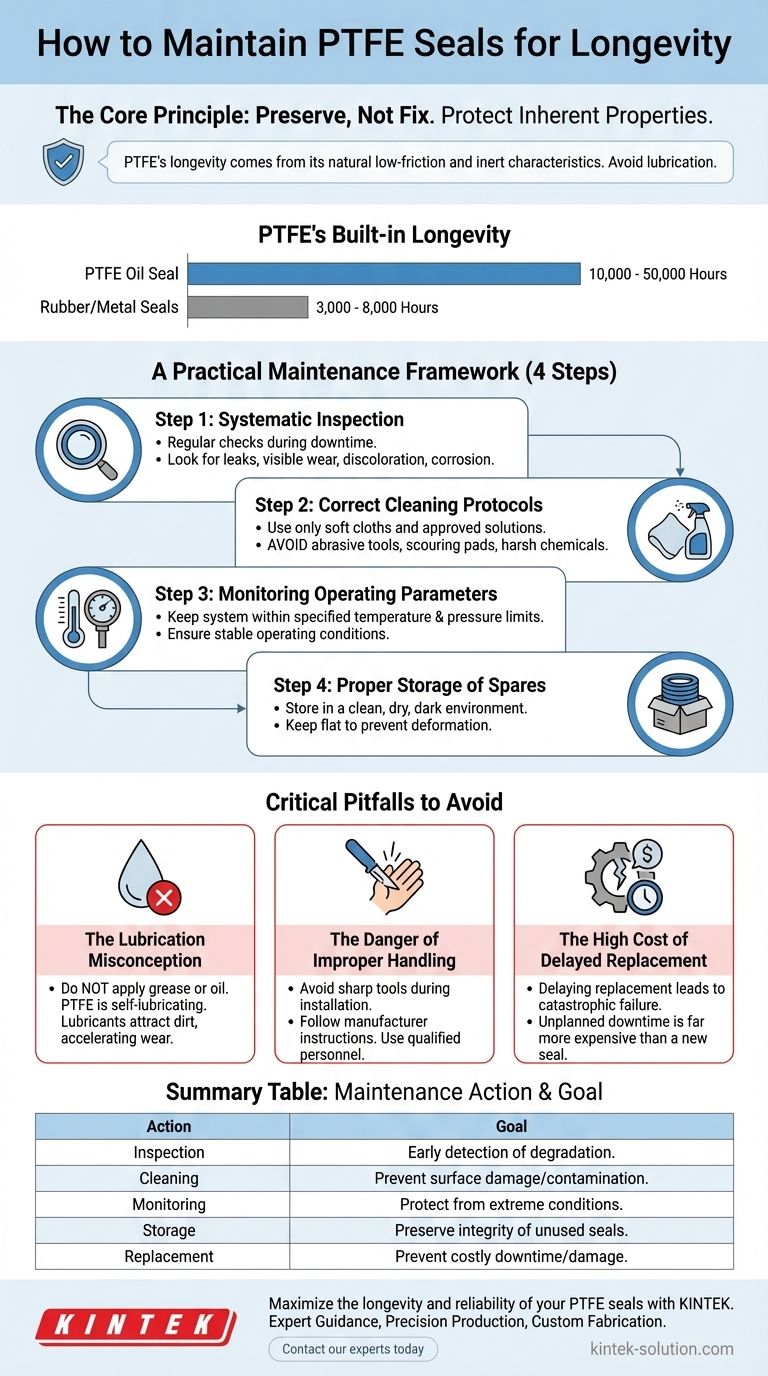

The Maintenance Philosophy: Preserving Inherent Strength

To effectively maintain PTFE, you must first understand why it's chosen. It offers exceptional durability due to its chemical inertness, wide operating temperature range, and extremely low coefficient of friction.

PTFE's Built-in Longevity

PTFE seals are engineered for endurance. Under proper conditions, a PTFE oil seal can last 10,000 to 50,000 hours, significantly outperforming rubber (3,000-8,000 hours) and metal seals.

This durability stems from its resistance to wear, chemical attack, and environmental stress. Your maintenance strategy should focus on enabling the seal to deliver this full service life.

The Goal: A Stable Operating Environment

The most common causes of premature PTFE seal failure are external factors, not material weakness. Maintenance is simply the practice of controlling the seal's environment to keep it within its designed operating parameters.

A Practical Maintenance Framework

A successful maintenance program is built on simple, consistent actions focused on inspection, cleaning, and operational awareness.

Step 1: Systematic Inspection

Regular inspection during planned equipment maintenance is your first line of defense. Look for clear signs of trouble.

Check for leaks, visible wear on the seal's lining, or discoloration. Also, inspect adjacent components for corrosion, which could indicate a compromised seal.

Step 2: Correct Cleaning Protocols

If cleaning is necessary, the method is critical. Use only soft cloths and manufacturer-approved cleaning solutions.

Never use abrasive tools, scouring pads, or harsh chemicals. These can create microscopic scratches on the seal surface, compromising its integrity and leading to premature failure.

Step 3: Monitoring Operating Parameters

PTFE is robust, but not invincible. Continuously operating the system beyond the seal's specified temperature and pressure limits is a primary cause of failure.

Ensure your system's operating conditions remain stable and within the design specifications of the seal.

Step 4: Proper Storage of Spares

Maintenance extends to the seals you haven't installed yet. Store spare PTFE seals in a clean, dry environment away from direct UV light or ozone.

Storing them flat and without compression prevents deformation, ensuring they are in perfect condition when needed.

Critical Pitfalls to Avoid

Understanding what not to do is as important as knowing what to do. Certain well-intentioned actions can severely damage PTFE seals.

The Lubrication Misconception

Do not apply traditional lubricants like oil or grease to PTFE seals or PTFE-lined components. The material is self-lubricating.

External lubricants attract and hold dirt, dust, and other contaminants. This turns the low-friction surface into an abrasive paste, which dramatically accelerates wear and causes the seal to fail.

The Danger of Improper Handling

Physical damage during installation or maintenance is a common failure mode. Avoid using sharp tools that could nick or scratch the sealing surface.

Likewise, using unqualified personnel for repairs can introduce new problems. Always follow manufacturer instructions for installation and replacement.

The High Cost of Delayed Replacement

A damaged or worn seal is a critical warning sign. Delaying its replacement to save on the cost of a part can lead to catastrophic equipment failure.

The resulting unplanned downtime and potential system damage will be far more expensive than the cost of a new seal.

Making the Right Choice for Your Goal

Your maintenance approach should align with your top operational priority.

- If your primary focus is maximizing uptime: Prioritize a proactive schedule of inspection and replace seals at the very first sign of wear or degradation.

- If your primary focus is reducing long-term costs: Emphasize correct handling, including the strict avoidance of external lubricants and proper storage of spares to maximize the life of every seal.

- If your primary focus is ensuring safety and reliability: Concentrate on strict adherence to the seal's operating parameters and the manufacturer's recommended replacement intervals.

Understanding and protecting the unique properties of PTFE is the definitive path to unlocking its full, long-lasting performance.

Summary Table:

| Maintenance Action | Key Practice | Goal |

|---|---|---|

| Inspection | Check for leaks, wear, discoloration during planned downtime. | Early detection of degradation. |

| Cleaning | Use soft cloths and approved solutions; avoid abrasives. | Prevent surface damage and contamination. |

| Monitoring | Ensure stable temperature/pressure within seal specifications. | Protect PTFE from extreme operating conditions. |

| Storage | Keep spares in a clean, dry, dark place, stored flat. | Preserve integrity of unused seals. |

| Replacement | Replace promptly at first sign of failure; do not delay. | Prevent costly equipment downtime and damage. |

Maximize the longevity and reliability of your PTFE seals with KINTEK.

Our precision-manufactured PTFE components—including seals, liners, and labware—are engineered for exceptional durability in the most demanding semiconductor, medical, laboratory, and industrial applications. By partnering with KINTEK, you gain access to:

- Expert Guidance: Get tailored advice on installation, maintenance, and optimal operating parameters to extend seal life.

- Precision Production: Ensure perfect fit and function with components made to the highest standards.

- Custom Fabrication: From prototypes to high-volume orders, we provide solutions designed specifically for your equipment's needs.

Don't let seal failure compromise your operations. Contact our experts today to discuss your requirements and ensure peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- How do PTFE and EPDM valve seats perform in actuated butterfly valves? Choose the Right Seal for Your Media

- Why are PTFE bushes considered self-lubricating? Achieve Maintenance-Free, Contamination-Free Motion

- Why is PTFE effective in anti-seize applications? Prevent Galling, Corrosion, and Seizing

- How do PTFE reducing flanges contribute to enhanced safety? Ensure Leak-Proof, Corrosion-Resistant Connections

- What design codes are used for PTFE structural bearings? A Guide to AASHTO, BS:5400 & IRC:83

- What are some tips for successfully machining PTFE? Master Precision Cuts for Soft, Heat-Sensitive Material

- What are the features of split-film PTFE gland packing? A High-Pressure Sealing Solution