The short answer is that PTFE (polytetrafluoroethylene) is considered self-lubricating because it physically transfers a microscopic film of its own material onto the mating surface during initial operation. This creates an ultra-low-friction, PTFE-on-PTFE interface, which eliminates the need for external oils or greases to ensure smooth movement.

The term "self-lubricating" can be misleading. PTFE isn't "wet" or oily; its lubricating property comes from creating a permanent, solid lubricant film on a partner surface, fundamentally changing the nature of the sliding contact.

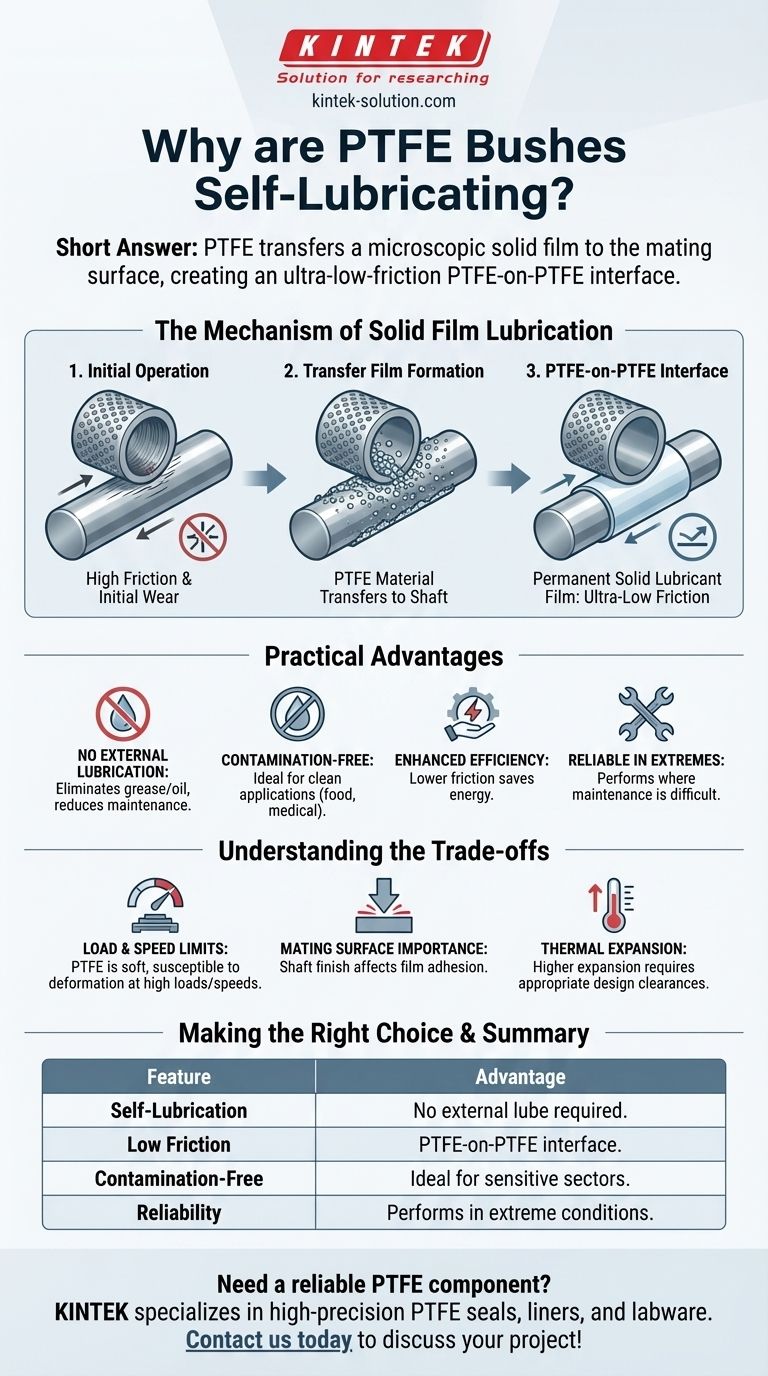

The Mechanism of Solid Film Lubrication

To understand why PTFE bushes work without external lubrication, we need to look at what happens at the microscopic level between the bush and the shaft it supports.

The Inherent Low Friction of PTFE

PTFE is a fluoropolymer with one of the lowest coefficients of friction of any known solid. Its molecular structure is incredibly stable and non-reactive, meaning other materials slide against it with very little resistance.

The "Transfer Film" Phenomenon

When a shaft first begins to rotate or slide within a PTFE bush, the initial friction is enough to "smear" a very thin, invisible layer of PTFE particles onto the metal surface of the shaft.

This process is known as creating a transfer film. The initial break-in period is critical for establishing this stable, lubricating layer.

Creating a PTFE-on-PTFE Interface

Once this transfer film is fully formed, the dynamic changes entirely. The PTFE bush is no longer sliding against a metal shaft.

Instead, the PTFE bush is sliding against the PTFE film that now coats the shaft. This PTFE-on-PTFE contact is what produces the material's signature low friction and smooth operation, effectively making the system self-lubricating for its entire service life.

Practical Advantages in Application

This unique lubricating mechanism provides significant advantages over traditional, externally lubricated bearings in many scenarios.

Eliminating External Lubrication

The most obvious benefit is the complete removal of any need for grease, oil, or periodic re-lubrication. This drastically reduces maintenance requirements and costs.

It also prevents failures caused by "dry running," where a traditional bearing runs out of its lubricant and suffers catastrophic wear.

Preventing Contamination

Because there are no liquid lubricants to leak or spread, PTFE bushes are ideal for applications where cleanliness is paramount. This includes food processing equipment, medical devices, and cleanroom machinery.

Enhancing System Efficiency

Lower friction means less energy is wasted overcoming resistance. This can lead to improved energy efficiency and smoother, more precise motion in mechanical systems.

Ensuring Reliability in Extreme Conditions

PTFE's properties make it suitable for applications where regular maintenance is difficult or impossible, such as in aerospace components, subsea equipment, or other inaccessible parts of a machine.

Understanding the Trade-offs

While powerful, the self-lubricating nature of PTFE is not a universal solution. An objective analysis requires understanding its limitations.

Load and Speed Limitations

PTFE is a relatively soft material. Compared to lubricated bronze or ball bearings, pure PTFE bushes have lower load-bearing capacity and maximum speed ratings. High loads can cause the material to deform or "cold flow" over time.

The Importance of the Mating Surface

The effectiveness of the transfer film is highly dependent on the surface finish of the mating shaft. A surface that is too rough will act like a file, rapidly abrading the PTFE. A surface that is too smooth may not allow the transfer film to adhere properly.

Thermal Expansion

PTFE has a significantly higher rate of thermal expansion than metals. Engineers must design assemblies with appropriate clearances to accommodate this expansion and prevent the bush from seizing at higher operating temperatures.

Making the Right Choice for Your Application

Selecting the right bearing material requires aligning its properties with your primary engineering goal.

- If your primary focus is maintenance-free operation in a clean environment: PTFE is an exceptional choice due to its solid, non-contaminating lubrication.

- If your primary focus is high-load or high-speed performance: You should investigate lubricated metallic bearings or polymer composites designed for higher mechanical stress.

- If your primary focus is silent, smooth, and simple operation: PTFE offers a compelling solution, provided your application operates well within its mechanical and thermal limits.

Ultimately, understanding that PTFE creates its own solid lubricant layer is the key to deploying it effectively.

Summary Table:

| Feature | Advantage |

|---|---|

| Self-Lubrication | No external grease or oil required; eliminates maintenance. |

| Low Friction | PTFE-on-PTFE interface ensures smooth, energy-efficient operation. |

| Contamination-Free | Ideal for food, medical, and cleanroom applications. |

| Reliability | Performs in extreme conditions where maintenance is impossible. |

Need a reliable, self-lubricating component for your application?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly suited to your needs, delivering maintenance-free operation and contamination control.

Contact us today to discuss your project and discover how our PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials