To be precise, split-film PTFE gland packing is a high-density sealing material woven from sintered, fully stretched PTFE yarns and then impregnated with a PTFE dispersion. This construction gives it a unique combination of high structural strength, resistance to compression, and dimensional stability. It is specifically engineered to perform reliably under conditions involving high pressure and high media velocity.

The core decision to use split-film PTFE packing is a choice for structural integrity. While all PTFE packings offer chemical resistance, this specific type excels at resisting extrusion and deformation in high-pressure pumps and valves, a critical factor for maintaining a long-lasting, reliable seal.

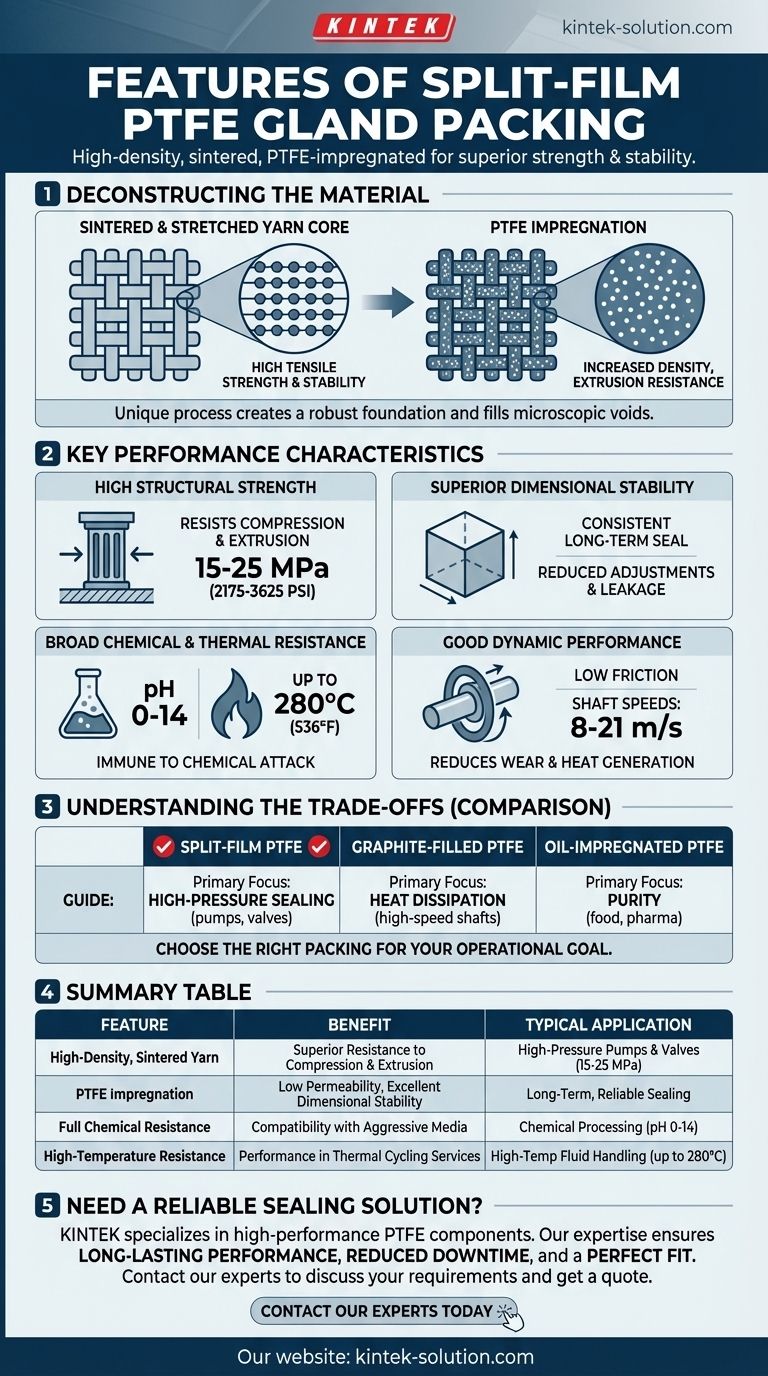

Deconstructing the Material and Method

To understand why this packing performs the way it does, we must first look at how it is made. Its properties are a direct result of its unique construction process.

The Sintered and Stretched Yarn Core

The process begins with PTFE yarns that are sintered (heated to fuse particles) and then fully stretched.

This multi-stage process aligns the PTFE molecules, creating a yarn with exceptionally high tensile strength and dimensional stability. It forms a robust foundation for the packing.

The Role of PTFE Impregnation

The woven structure is then impregnated with a PTFE dispersion, which fills any microscopic voids within the braid.

This step is critical. It dramatically increases the packing's density, making it less permeable and far more resistant to being extruded or pushed out of the stuffing box under high pressure.

Key Performance Characteristics Explained

The combination of a strong yarn core and dense impregnation results in a set of specific performance advantages ideal for demanding industrial environments.

High Structural Strength and Density

This is the primary feature of split-film PTFE. Its dense, strong structure provides excellent resistance to compression and extrusion.

This makes it an ideal choice for applications with high system pressures, typically in the range of 15 to 25 MPa (2175 to 3625 PSI), where softer packings would fail.

Superior Dimensional Stability

Unlike softer materials that can deform or "creep" over time, split-film PTFE maintains its shape and volume under continuous load.

This stability ensures a consistent, long-term seal, reducing the need for frequent gland adjustments and minimizing leakage.

Broad Chemical and Thermal Resistance

Inheriting the core properties of PTFE, this packing is virtually immune to chemical attack across the entire pH range of 0 to 14.

It also maintains its integrity in temperatures up to 280°C (536°F), making it suitable for a wide array of aggressive chemical and high-temperature services.

Good Performance in Dynamic Applications

Despite its density, the packing retains the characteristic low friction of PTFE. It can handle shaft surface speeds between 8 and 21 m/s.

This low friction reduces wear on equipment shafts and sleeves while minimizing heat generation, which is a common cause of packing failure.

Understanding the Trade-offs: Split-Film vs. Other PTFE Packings

Choosing the right packing requires understanding not only its strengths but also where other variants might be more suitable. The "best" packing is always specific to the application's primary challenge.

Split-Film vs. Graphite-Filled PTFE

Graphite-filled PTFE packing contains graphite particles integrated into the yarn. Its key advantage is superior thermal conductivity.

If your primary challenge is dissipating heat from a very high-speed rotating shaft, graphite-filled PTFE is the better choice. Split-film PTFE is superior when the primary challenge is high fluid pressure.

Split-Film vs. Oil-Impregnated PTFE

Oil-impregnated PTFE packing is lubricated with a special silicone oil, giving it an extremely low coefficient of friction right from start-up. Its main purpose is to serve applications where purity is paramount.

This makes it the go-to choice for the food, pharmaceutical, and paper industries, where product contamination is unacceptable. Split-film PTFE is a more general-purpose solution for aggressive chemical and high-pressure duties where trace contamination is not the main concern.

Making the Right Choice for Your Application

Your operational goal should dictate your material selection. Use the following points as a guide to match the packing to the problem you are solving.

- If your primary focus is high-pressure sealing: Choose split-film PTFE for its unmatched structural integrity and resistance to extrusion in pumps and valves.

- If your primary focus is managing heat on high-speed shafts: Select graphite-filled PTFE for its superior ability to conduct heat away from the dynamic sealing surface.

- If your primary focus is preventing product contamination: Use oil-impregnated PTFE, especially in food-grade, pharmaceutical, or other sanitary applications.

By aligning the packing’s inherent strengths with your specific operational demand, you ensure optimal performance and equipment reliability.

Summary Table:

| Feature | Benefit | Typical Application |

|---|---|---|

| High-Density, Sintered Yarn | Superior resistance to compression and extrusion | High-pressure pumps & valves (15-25 MPa) |

| PTFE Impregnation | Low permeability and excellent dimensional stability | Long-term, reliable sealing with minimal adjustment |

| Full Chemical Resistance (pH 0-14) | Compatibility with aggressive media | Chemical processing |

| High-Temperature Resistance (up to 280°C) | Performance in thermal cycling services | High-temperature fluid handling |

| Low Friction | Reduced shaft wear and heat generation | Dynamic sealing (8-21 m/s shaft speeds) |

Need a reliable sealing solution for high-pressure or aggressive chemical applications?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing. Our expertise in precision production ensures you get a seal that delivers:

- Long-lasting performance in the most demanding conditions.

- Reduced downtime from frequent adjustments or failures.

- A perfect fit, from prototype to high-volume production.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can fabricate the right PTFE solution for you.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness rating of Teflon balls? Understanding PTFE's Softness for Optimal Use

- Why is the low friction coefficient of PTFE Teflon washers advantageous? Achieve Peak Efficiency and Durability

- Which industries commonly use PTFE seals and why? Unlock Unmatched Performance in Harsh Environments

- What are the key characteristics of PTFE Enveloped Gaskets? Solve Demanding Sealing Challenges

- What are the main advantages of using PTFE over rubber in rotary shaft seals? Superior Performance in Extreme Conditions

- What makes PTFE instrumentation tube fittings highly reliable and durable? Superior Chemical & Thermal Resistance

- What are the key properties of Expanded PTFE (EPTFE) gaskets? Solve Leaks on Damaged Flanges

- What factors should be considered when choosing between PTFE and rubber washers? Optimize Sealing for Extreme or Everyday Use