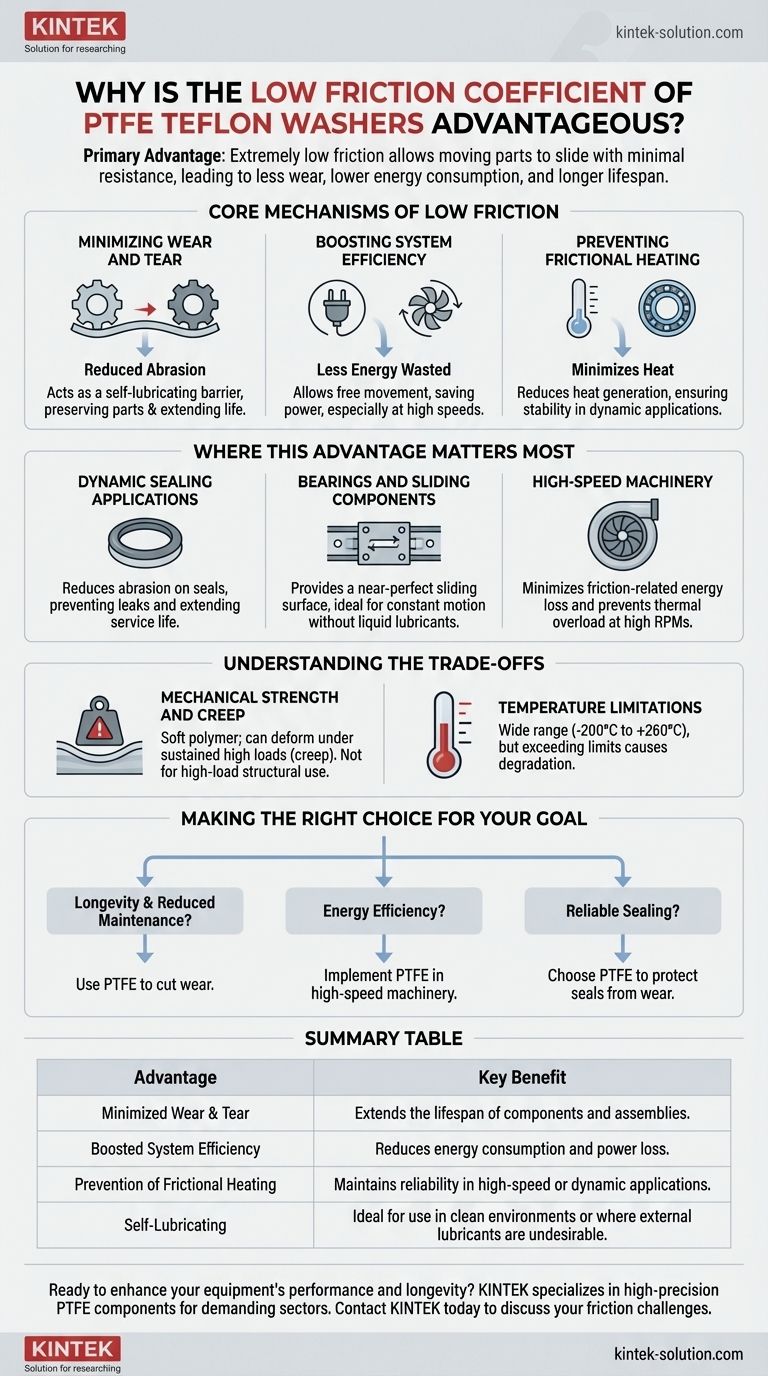

The primary advantage is simple. The extremely low friction coefficient of PTFE Teflon washers allows moving parts to slide against each other with minimal resistance. This directly translates to less wear, lower energy consumption, and a significantly longer lifespan for the components involved.

In any mechanical system, friction is a constant force that degrades parts and wastes energy. PTFE's uniquely low friction coefficient provides a powerful solution, enabling smoother, more efficient, and more durable operation in critical applications where other materials would fail.

The Core Mechanisms of Low Friction

The benefits of low friction are not abstract; they manifest as tangible improvements in mechanical performance. Understanding these mechanisms is key to leveraging PTFE effectively in any design.

Minimizing Wear and Tear

Friction is a physical abrasive force. When two surfaces rub together, material is slowly worn away, leading to component failure over time.

A PTFE washer acts as a protective, self-lubricating barrier. By drastically reducing this rubbing force, it preserves the integrity of the parts it separates, extending the entire assembly's operational life.

Boosting System Efficiency

Every mechanical system must overcome friction to do its job. This wasted effort requires more energy input, often lost as heat.

Because PTFE allows parts to move almost freely, less energy is wasted. This results in significant power savings, especially in high-speed or continuously running equipment like impellers and motors.

Preventing Frictional Heating

In dynamic or high-speed applications, friction can generate intense localized heat. This heat can cause materials to deform, degrade seals, or break down lubricants.

PTFE's low friction coefficient inherently minimizes this heat generation at the source, ensuring components remain stable and perform reliably under demanding conditions.

Where This Advantage Matters Most

The theoretical benefits of low friction become critical advantages in specific, demanding environments where standard materials would quickly degrade.

Dynamic Sealing Applications

Components like O-rings and seals must maintain a tight barrier while moving. High friction would quickly abrade the seal, causing leaks.

PTFE washers reduce this wear, extending the service life of the seal and ensuring reliability, a crucial factor in the automotive and aerospace industries.

Bearings and Sliding Components

For gears, sliders, and bearings, constant motion is their primary function. Friction is the primary enemy, causing performance loss and eventual seizure.

PTFE provides a near-perfect sliding surface, making it an ideal material for these components and reducing the need for external liquid lubricants.

High-Speed Machinery

In devices that operate at high RPMs, even a small amount of friction is magnified into a major source of energy loss and heat.

Using PTFE washers in these assemblies ensures that more of the input power is converted into useful work, improving overall efficiency and preventing thermal overload.

Understanding the Trade-offs

While its low friction is a powerful asset, PTFE is not a universal solution. An objective technical assessment requires acknowledging its limitations.

Mechanical Strength and Creep

PTFE is a relatively soft polymer, not a metal. Under sustained, high-pressure loads, it can slowly deform over time in a process known as creep.

For high-load structural applications, a metal washer may be necessary to provide the required compressive strength and rigidity.

Temperature Limitations

The operational temperature range of PTFE is exceptionally wide (typically -200°C to +260°C), but it is not infinite.

Exceeding its upper temperature limit will cause the material to degrade and lose its beneficial properties. For extreme-heat applications, ceramic or specialized metal components are required.

Making the Right Choice for Your Goal

To determine if a PTFE washer is the correct choice, align its primary benefit with your system's most critical need.

- If your primary focus is longevity and reduced maintenance: Use PTFE between moving parts to drastically cut down on wear and extend service intervals.

- If your primary focus is energy efficiency: Implement PTFE in high-speed or continuously operating machinery to minimize power loss due to friction.

- If your primary focus is reliable sealing in dynamic systems: Choose PTFE to protect seals from abrasive wear, preventing leaks and premature failure.

Ultimately, leveraging the low friction of PTFE is a strategic decision to build more robust, efficient, and reliable mechanical systems.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimized Wear & Tear | Extends the lifespan of components and assemblies. |

| Boosted System Efficiency | Reduces energy consumption and power loss. |

| Prevention of Frictional Heating | Maintains reliability in high-speed or dynamic applications. |

| Self-Lubricating | Ideal for use in clean environments or where external lubricants are undesirable. |

Ready to enhance your equipment's performance and longevity?

PTFE's low friction is a game-changer for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom washers—that deliver these critical advantages.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Contact KINTEK today to discuss how our PTFE solutions can solve your friction-related challenges and build a more robust, efficient system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments