Expanded PTFE (EPTFE) gaskets are defined by a unique combination of extreme chemical inertness, a wide operational temperature range, and remarkable mechanical properties. Unlike standard PTFE, the "expanded" manufacturing process creates a multi-directional fibrous structure, granting it superior creep resistance and the ability to conform to imperfect surfaces under low bolt loads.

The core advantage of Expanded PTFE is not just its resilience to harsh environments, but its ability to solve a common engineering problem: creating and maintaining a reliable seal on irregular, damaged, or fragile flange surfaces where other materials would fail over time.

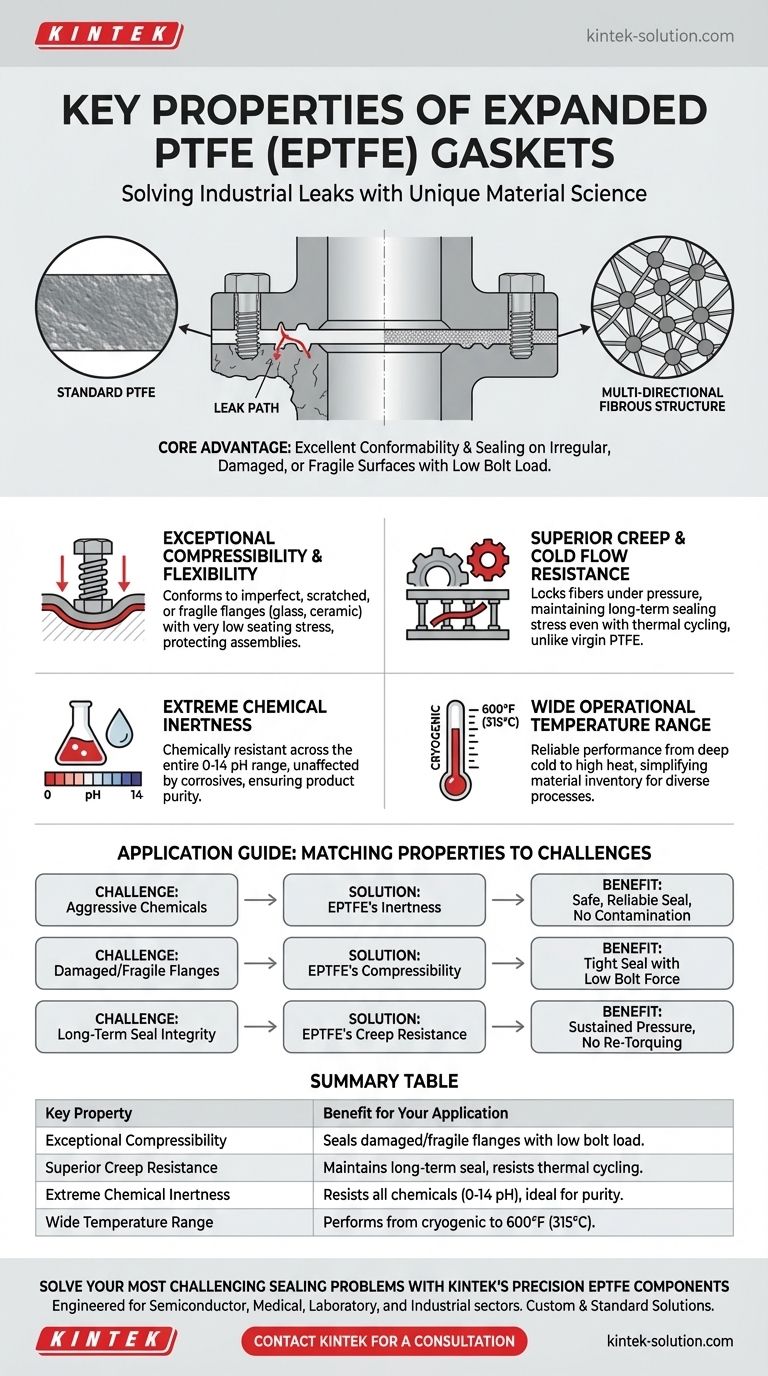

The Core Mechanical Advantage: Solving Real-World Leaks

The physical structure of EPTFE is its primary differentiator. This structure directly addresses the most common causes of gasket failure in demanding industrial applications.

Exceptional Compressibility and Flexibility

Expanded PTFE is highly conformable. It requires very low seating stress to create an effective seal, even on surfaces with minor scratches, pitting, or warping.

This softness makes it an ideal choice for fragile flange assemblies, such as those made from glass-lined steel, plastic, or ceramic, which could crack under the high bolt loads required for harder gasket materials.

Superior Resistance to Creep and Cold Flow

This is the most critical advantage EPTFE holds over standard, or "virgin," PTFE. Creep (or cold flow) is the tendency of a material to deform permanently under a sustained load, which leads to a loss of bolt torque and, eventually, a leak.

The multi-directional fibrous structure of EPTFE locks together under compression, significantly resisting this deformation. This ensures the gasket maintains its sealing pressure long after installation, even under thermal cycling and pressure fluctuations.

Unmatched Environmental Resilience

Beyond its mechanical strengths, EPTFE inherits the well-known environmental stability of the PTFE polymer, making it suitable for the most aggressive services.

Extreme Chemical Inertness

EPTFE gaskets are chemically resistant across the entire 0-14 pH range. They are unaffected by the most corrosive acids, caustics, and solvents.

This non-reactive and non-contaminating nature makes them essential in industries like pharmaceuticals, food processing, and chemical manufacturing where product purity is paramount.

Wide Operational Temperature Range

EPTFE performs reliably in a vast temperature window, from cryogenic conditions up to approximately 600°F (315°C).

This allows a single gasket material to be standardized across numerous plant processes, from low-temperature services to high-temperature chemical reactions, simplifying inventory and reducing the risk of material misapplication.

High-Pressure Capability

Depending on the specific gasket design and the flange assembly, EPTFE can seal pressures upwards of 3000 psi.

It is critical to note that maximum pressure rating is not a property of the material alone; it is a function of the entire system, including flange type, bolt material, and installation practice.

Understanding the Trade-offs and Limitations

While highly capable, EPTFE is not a universal solution. Understanding its limitations is key to successful application.

Proper Installation is Paramount

The same softness that allows EPTFE to conform so well also makes it susceptible to damage from mishandling. It can also be over-compressed if excessive bolt torque is applied, which can impair its sealing ability.

Always follow the manufacturer's specified torque values to achieve the ideal compressive stress without crushing the material's fibrous structure.

Not Ideal for Abrasive Media

The soft nature of EPTFE means it is not well-suited for applications involving abrasive slurries or powders. These media can erode the gasket material over time, leading to seal failure.

Cost Considerations

As a high-performance specialty material, Expanded PTFE typically carries a higher initial cost than standard non-asbestos or elastomeric gaskets. However, this cost is often justified by its longevity, reliability, and the prevention of costly leaks and downtime in critical applications.

How to Apply This to Your Project

Choosing the right gasket material depends entirely on the primary challenge you need to solve.

- If your primary focus is sealing aggressive chemicals: EPTFE's near-total chemical inertness across the full pH range makes it one of the safest and most reliable choices.

- If your primary focus is dealing with damaged or uneven flanges: Its excellent compressibility allows you to achieve a tight seal with low bolt force where more rigid gaskets would inevitably fail.

- If your primary focus is maintaining long-term seal integrity: EPTFE's resistance to creep and cold flow is the critical property that ensures the gasket stays sealed under continuous pressure and temperature.

By matching these specific properties to your application's demands, you can confidently leverage Expanded PTFE to solve your most challenging sealing problems.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Exceptional Compressibility | Seals effectively on damaged, warped, or fragile flanges with low bolt load. |

| Superior Creep Resistance | Maintains seal integrity long-term, even under thermal cycling and pressure. |

| Extreme Chemical Inertness | Resists virtually all chemicals (0-14 pH), ideal for corrosive or pure processes. |

| Wide Temperature Range | Performs reliably from cryogenic conditions up to 600°F (315°C). |

Solve your most challenging sealing problems with KINTEK's precision EPTFE components.

Our expanded PTFE gaskets, seals, and custom fabrications are engineered for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with precision manufacturing to deliver reliable, long-lasting performance that prevents costly downtime.

Whether you need a standard part or a custom solution from prototype to high-volume production, we are here to help.

Contact KINTEK today for a consultation and let our experts help you specify the perfect seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support