The hardness of Teflon (PTFE) balls is most commonly cited on two different scales: approximately 55 on the Shore D scale and R58 on the Rockwell R scale. These values indicate that Teflon is a relatively soft plastic. Understanding this softness is the key to correctly applying it, as its primary strengths are not mechanical, but chemical and thermal.

While Teflon balls have a defined hardness, their true value lies in their unparalleled chemical resistance and extremely low friction. Their softness and poor wear resistance are the critical trade-offs you must consider for any application.

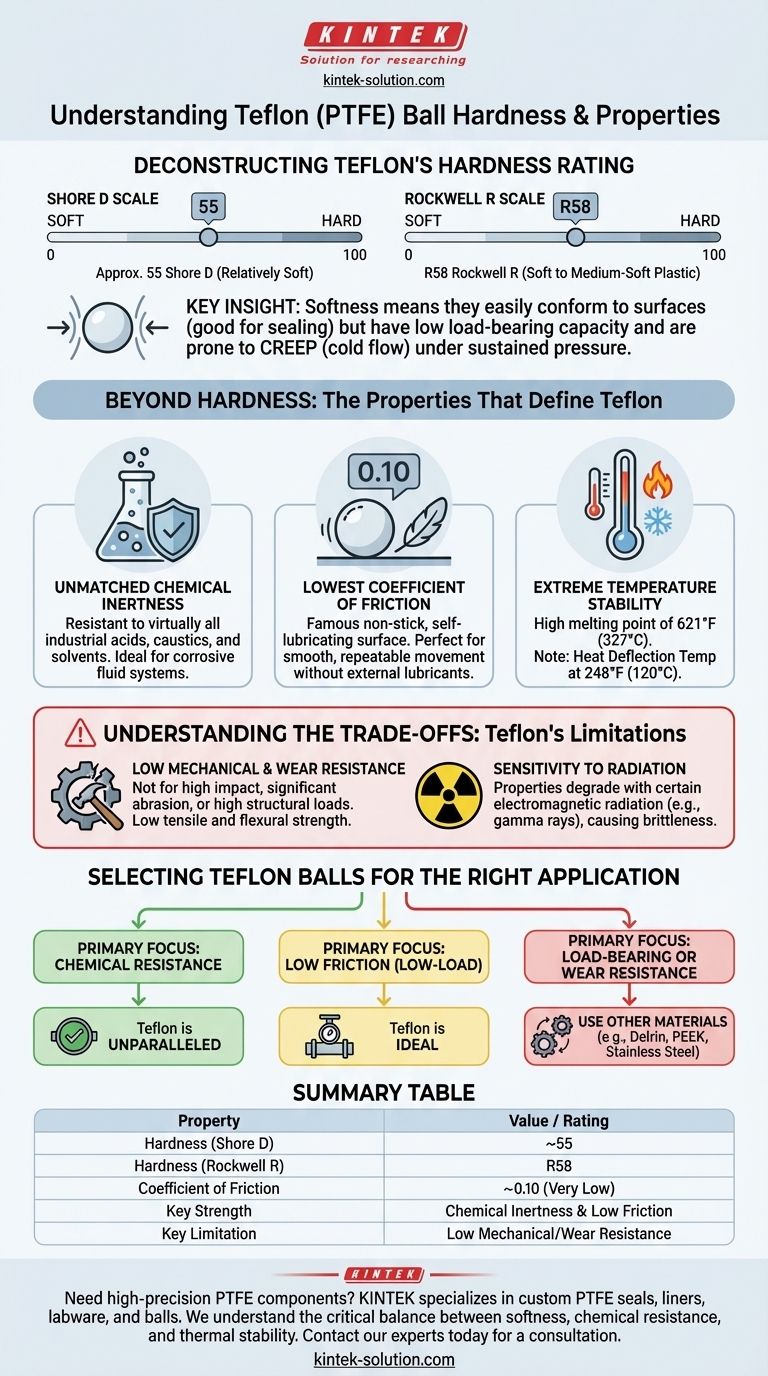

Deconstructing Teflon's Hardness Rating

To properly evaluate Teflon, you must understand what its hardness value implies for real-world performance. It's not just a number, but an indicator of its mechanical behavior.

The Two Common Scales: Shore D and Rockwell R

The values 55 Shore D and R58 Rockwell place Teflon firmly in the category of soft to medium-soft plastics. For comparison, a hard nylon might be over 80 Shore D, and harder engineering plastics can be much higher.

This softness means Teflon balls can be easily scratched or deformed under concentrated loads. They are not designed for high-pressure or abrasive applications where mechanical integrity is the primary concern.

What Softness Means for Performance

The relatively low hardness directly results in several key behaviors. Teflon balls will readily conform to irregular surfaces, which can be an advantage for creating effective seals in valves.

However, this same property means they have low load-bearing capacity. Under sustained pressure, a phenomenon known as creep (cold flow) will occur, where the material will slowly and permanently deform, even at room temperature.

Beyond Hardness: The Properties That Define Teflon

Focusing solely on hardness misses the point of Teflon. Engineers choose this material for its unique combination of other world-class properties that few other polymers can match.

Unmatched Chemical Inertness

Teflon's defining characteristic is its extreme resistance to chemical attack. It is resistant to virtually all industrial acids, caustics, and solvents.

This makes Teflon balls an excellent choice for check valves, mixing beads, and bearing points inside systems handling highly corrosive or pure fluids where material leaching is unacceptable.

The Lowest Coefficient of Friction

Teflon is famous for its non-stick, self-lubricating surface, with a coefficient of friction around 0.10. This means parts can move against it with minimal energy loss and without external lubricants.

This property is ideal for applications like ball-and-detent mechanisms in toggle switches, light-duty bearings, and flow meter components where smooth, repeatable movement is critical.

Extreme Temperature Stability

Teflon has a very high melting point of 621°F (327°C), allowing it to survive in high-temperature environments.

However, it is crucial to note its much lower heat deflection temperature of 248°F (120°C). This is the temperature at which it will begin to deform under a given load. While it won't melt, it will lose its shape and mechanical integrity.

Understanding the Trade-offs: Teflon's Limitations

To use Teflon effectively, you must be acutely aware of its weaknesses. Misunderstanding these limitations is the most common source of failure in Teflon applications.

Low Mechanical and Wear Resistance

As stated in technical specifications, Teflon has "lower mechanical and wear resistance properties compared to other plastic materials." It has low tensile and flexural strength.

It should never be used in applications involving high impact, significant abrasion, or high structural loads. In these scenarios, harder plastics like Delrin (Acetal), PEEK, or metals are required.

Sensitivity to Radiation

The properties of Teflon can be degraded by exposure to certain types of electromagnetic radiation, such as gamma rays. This can cause the material to become brittle and lose its desirable qualities.

This is a niche but critical consideration for applications in aerospace, medical sterilization, or nuclear environments.

Selecting Teflon Balls for the Right Application

Choosing the right material is about matching its unique profile to your primary goal. Teflon is an exceptional material when used correctly and a poor one when misapplied.

- If your primary focus is chemical resistance: Teflon is an unparalleled choice for applications like check valves or mixing beads in corrosive environments.

- If your primary focus is low friction in a low-load system: Its self-lubricating properties make it ideal for flow meters, light-duty bearings, and toggle switches.

- If your primary focus is load-bearing or wear resistance: You must look to other materials like Delrin (Acetal), PEEK, or even stainless steel, as Teflon will likely fail.

Understanding these trade-offs ensures you are leveraging Teflon for its unique strengths, not its weaknesses.

Summary Table:

| Property | Value / Rating |

|---|---|

| Hardness (Shore D) | ~55 |

| Hardness (Rockwell R) | R58 |

| Coefficient of Friction | ~0.10 (Very Low) |

| Key Strength | Chemical Inertness & Low Friction |

| Key Limitation | Low Mechanical/Wear Resistance |

Need high-precision PTFE components that leverage Teflon's unique properties?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and balls for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between PTFE's softness, its chemical resistance, and its thermal stability. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the right component for your specific application, avoiding the pitfalls of misapplication.

Let's discuss your project requirements. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance