PTFE balls are available in a wide range of standard sizes. Typically, you can source them in diameters from 3mm up to 100mm, accommodating a vast array of industrial, chemical, and mechanical applications.

While the size range of PTFE balls is broad, the critical factor for any application is matching the required dimensional tolerance and material grade to the specific performance demands.

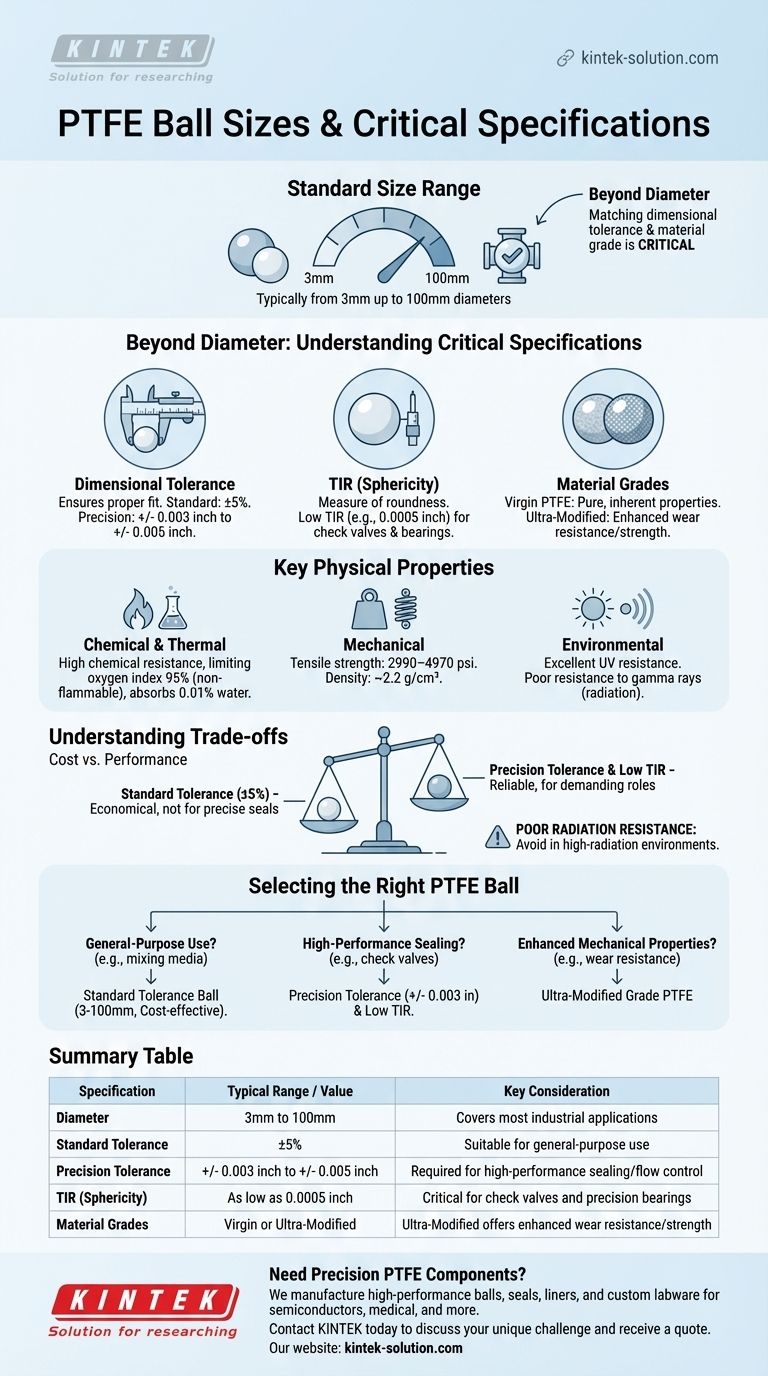

Beyond Diameter: Understanding Critical Specifications

Choosing the right PTFE ball requires looking past the simple diameter measurement. Factors like tolerance, roundness, and material composition are what truly define the component's performance in a given application.

Standard Size Range

The most common off-the-shelf sizes for PTFE balls range from 3mm to 100mm. This covers everything from small check valves to larger mixing and flotation applications.

The Importance of Dimensional Tolerance

Tolerance defines the permissible limit of variation in a ball's diameter. It is a critical specification for ensuring a proper fit and consistent performance.

You will typically encounter two types of tolerance specifications:

- Standard Tolerance: Often expressed as a percentage, such as ±5%, this is common for general-purpose applications where precision is not the primary concern.

- Precision Tolerance: For high-performance uses, a tighter tolerance is specified, such as +/- 0.003 inch for smaller balls or +/- 0.005 inch for larger ones.

What is TIR (Total Indicator Reading)?

TIR is a measure of a ball's sphericity, or how perfectly round it is. A lower TIR value, such as 0.0005 inch, indicates a more perfectly spherical ball.

This is crucial in applications like check valves and precision bearings, where a non-uniform shape could cause leaks or inconsistent operation.

Material Grades: Virgin vs. Modified

The grade of PTFE impacts its physical properties. The two primary grades available are:

- Virgin PTFE: This is pure, unadulterated Polytetrafluoroethylene, offering the material's inherent properties.

- Ultra-Modified PTFE: These grades include fillers or undergo special processing to enhance specific characteristics, such as wear resistance or compressive strength.

Key Physical Properties of PTFE

Understanding the inherent properties of PTFE is essential to confirm its suitability for your operating environment.

Chemical and Thermal Stability

PTFE exhibits extremely high chemical resistance and thermal stability. It has a limiting oxygen index of 95%, making it non-flammable, and absorbs only 0.01% water over 24 hours.

Mechanical Characteristics

The tensile strength of PTFE generally falls between 2990 and 4970 psi. Its density is approximately 2.2 g/cm³.

Environmental Resistance

PTFE has excellent resistance to UV radiation, making it suitable for outdoor applications. However, it is important to note that it has poor resistance to other forms of radiation, such as gamma rays.

Understanding the Trade-offs

Making an informed decision involves balancing performance requirements with cost and material limitations.

Standard vs. Precision

The primary trade-off is cost versus performance. A ball with a standard ±5% tolerance is significantly more economical but is unsuitable for applications requiring a precise seal or consistent flow rate.

Precision-ground balls with tight tolerances and a low TIR ensure reliability in demanding roles but come at a higher cost.

The Limitation of Radiation Resistance

While PTFE is exceptionally versatile, its poor resistance to high-energy radiation is a critical limitation. It should not be used in nuclear applications or high-radiation space environments without proper shielding, as the radiation can degrade the material's molecular structure.

Selecting the Right PTFE Ball for Your Application

Use your specific goal to guide your selection criteria.

- If your primary focus is general-purpose use (e.g., mixing media): A standard tolerance ball within the 3mm to 100mm range is likely sufficient and cost-effective.

- If your primary focus is high-performance sealing or flow control (e.g., check valves): You must specify a precision tolerance (e.g., +/- 0.003 inch) and a low TIR to ensure proper function.

- If your primary focus is enhanced mechanical properties (e.g., wear resistance): Consider an ultra-modified grade of PTFE, which may offer better performance than standard virgin PTFE.

Ultimately, defining your application's tolerance and environmental requirements is the key to selecting the correct PTFE ball.

Summary Table:

| Specification | Typical Range / Value | Key Consideration |

|---|---|---|

| Diameter | 3mm to 100mm | Covers most industrial applications |

| Standard Tolerance | ±5% | Suitable for general-purpose use |

| Precision Tolerance | +/- 0.003 inch to +/- 0.005 inch | Required for high-performance sealing/flow control |

| TIR (Sphericity) | As low as 0.0005 inch | Critical for check valves and precision bearings |

| Material Grades | Virgin or Ultra-Modified | Ultra-Modified offers enhanced wear resistance/strength |

Need Precision PTFE Components?

Selecting the right PTFE ball with the correct tolerance, sphericity, and material grade is critical to your application's success and longevity.

KINTEK manufactures high-performance PTFE components—including precision balls, seals, liners, and custom labware—for the semiconductor, medical, laboratory, and specialized industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us help you solve your unique challenge. Contact KINTEK today to discuss your specifications and receive a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What material was considered as an alternative to Turcite for making fork bushes, and why? Uncover the PTFE vs. Acetal Trade-off

- Where are PTFE V-rings commonly applied? Sealing Solutions for Harsh Industrial Environments

- Why is Teflon gland packing considered a future-proof solution for industrial sealing systems? Unmatched Chemical & Thermal Resilience

- How do you select the right PTFE gasket for an application? A Guide to Matching Material to Your Demands

- What is Teflon Lined Carbon Steel Pipe, and what are its properties? A Cost-Effective Solution for Corrosive Fluids

- What is a PTFE sliding elastomeric bearing? A Guide to Managing Large Structural Movements

- What are PTFE bearing pads and what are their main features? The Ultimate Guide to Low-Friction Structural Support

- What are some unique features of expanded PTFE gaskets? Superior Conformability & Creep Resistance