In short, PTFE V-rings are predominantly applied in demanding industrial settings like hydraulic cylinders, presses, and a wide range of valves. Their selection is driven by the need for a robust seal that can withstand high pressure, aggressive chemicals, and significant temperature ranges where lesser materials would fail.

The specific application is less important than the conditions it presents. PTFE V-rings are chosen for dynamic sealing applications in harsh environments where chemical inertness, low friction, and durability are critical operational requirements.

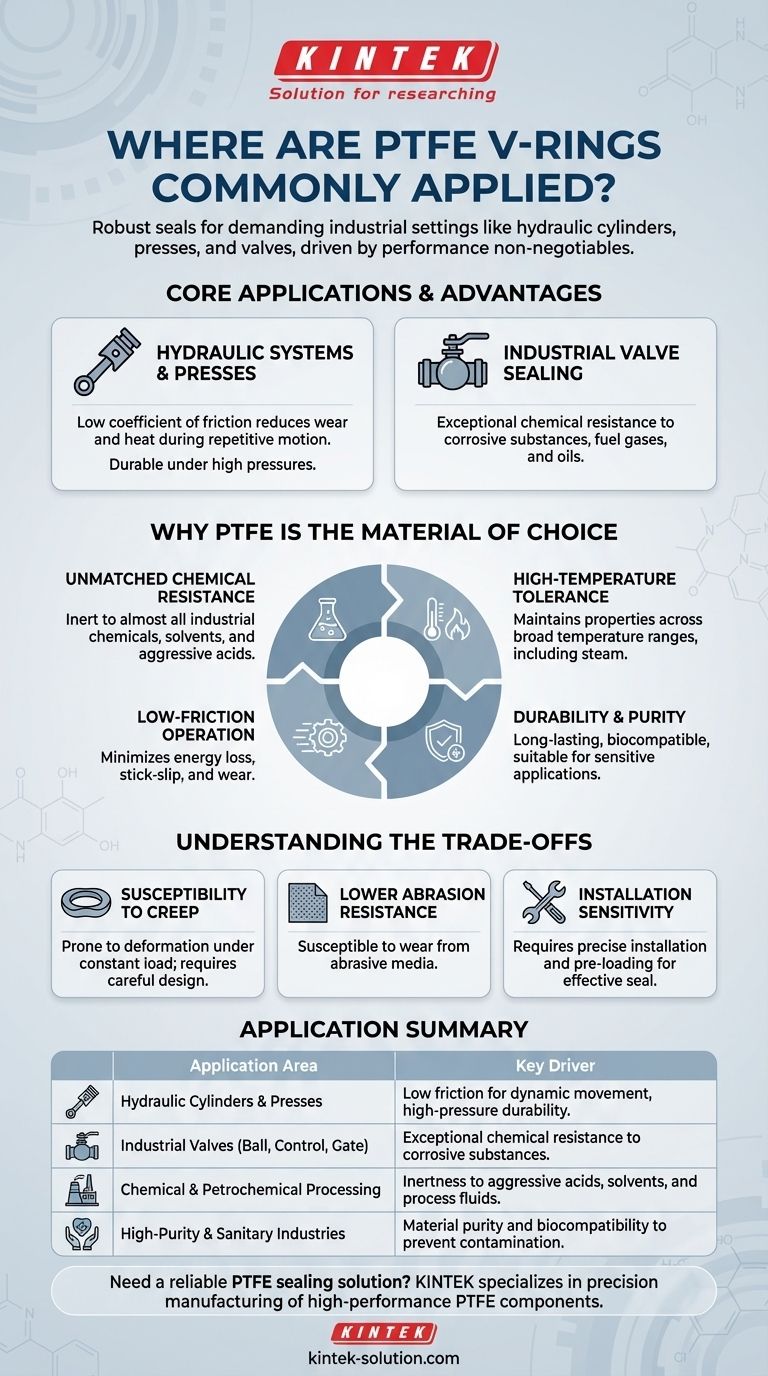

Core Applications: Where Performance is Non-Negotiable

The use cases for PTFE V-rings are concentrated in machinery and systems where sealing failure leads to significant downtime or safety risks. The design of a V-ring set provides a reliable seal under high pressure and dynamic movement.

Hydraulic Systems and Presses

PTFE V-rings are a standard in heavy-duty hydraulic cylinders and presses. The key advantage is their low coefficient of friction, which reduces wear and heat generation during the repetitive motion of a piston rod or ram.

Their durability ensures a long service life even under the high pressures characteristic of these systems.

Industrial Valve Sealing

The chemical industry relies heavily on PTFE's properties for valve sealing. V-rings are commonly found in ball valves, control valves, gate valves, and globe valves.

Here, the primary driver is PTFE's exceptional chemical resistance. The seal maintains its integrity even when exposed to corrosive substances, strong chemicals, fuel gases, and various oils.

The Underlying Principle: Why PTFE is the Material of Choice

To understand where V-rings are used, you must first understand the fundamental advantages of Polytetrafluoroethylene (PTFE) as a sealing material. Its unique combination of properties makes it a premier problem-solver in engineering.

Unmatched Chemical Resistance

PTFE is inert to almost all industrial chemicals and solvents. This makes it the default choice for equipment in chemical processing, petrochemical plants, and pharmaceutical manufacturing, where it handles everything from aggressive acids to high-purity process fluids.

High-Temperature Tolerance

PTFE maintains its key properties across a broad temperature range, withstanding conditions that would degrade or destroy many other polymers. This stability is essential for systems involving steam, heated fluids, or extreme environmental temperatures.

Low-Friction Operation

Often marketed under the brand name Teflon, PTFE's incredibly low friction is critical for dynamic applications. It allows components to move smoothly against the seal, minimizing energy loss, stick-slip phenomena, and mechanical wear.

Durability and Purity

The material's robust nature ensures a long-lasting seal, reducing maintenance cycles. Furthermore, its inherent purity and biocompatibility make it suitable for sensitive applications in the food, medical, and semiconductor industries, where contamination is not an option.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations, which can influence design and application choices.

Susceptibility to Creep

PTFE can be prone to "creep," or cold flow, meaning it can slowly deform over time when under a constant load. This must be accounted for in the engineering design, often by incorporating fillers (like glass or carbon) or by using spring-energized seals.

Lower Abrasion Resistance

Compared to some harder polymers, pure PTFE can be susceptible to wear from abrasive media. In applications with slurries or particulates, a filled grade of PTFE or an alternative material may be more appropriate.

Installation Sensitivity

V-ring sets require proper installation and pre-loading to function correctly. Unlike a simple O-ring, the series of nested rings must be compressed correctly to create an effective seal, requiring a higher degree of technical precision.

Making the Right Choice for Your Goal

Selecting the correct seal involves matching the material's properties and the seal's design to your primary operational challenge.

- If your primary focus is sealing high-pressure, dynamic systems like hydraulic cylinders: PTFE V-rings are an excellent choice due to their low-friction and durable sealing capabilities.

- If your primary focus is containing aggressive chemicals in process valves or equipment: The chemical inertness of PTFE makes it an industry standard, with V-rings being a top option for valve stems.

- If your primary focus is a high-purity or sanitary application: PTFE is the right material, but the form may vary; O-rings, gaskets, or bellows might be more suitable than V-rings depending on the specific mechanical need.

Ultimately, understanding the unique properties of PTFE is the key to selecting the correct sealing solution for any demanding application.

Summary Table:

| Application Area | Key Driver for Using PTFE V-Rings |

|---|---|

| Hydraulic Cylinders & Presses | Low friction for dynamic movement, high-pressure durability |

| Industrial Valves (Ball, Control, Gate) | Exceptional chemical resistance to corrosive substances |

| Chemical & Petrochemical Processing | Inertness to aggressive acids, solvents, and process fluids |

| High-Purity & Sanitary Industries | Material purity and biocompatibility to prevent contamination |

Need a reliable PTFE sealing solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom V-rings, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide durable seals that offer superior chemical resistance, low friction, and long-lasting performance.

We work with you from prototype to high-volume production to ensure the perfect seal for your specific operational challenges. Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the sealing capabilities of PTFE lined check valves? Achieve Superior Corrosion Resistance

- Are all PTFE gasket sheets suitable for food applications? The Critical Virgin vs. Filled PTFE Distinction

- What is the shelf life of Teflon encapsulated silicone o-rings? Discover Their Indefinite Durability

- What are symptoms of temperature-induced PTFE lip seal failure? Identify the Cause of Your Leaks

- What are the two main methods for manufacturing pure PTFE gaskets? Molding vs. Cutting Explained

- How does PTFE enhance baseball equipment? Unlock Faster Swings and Longer-Lasting Gear

- Why are new PTFE gasket products entering the market? To Solve Critical Creep and Cold Flow Issues

- What are the key properties of PTFE? Unmatched Chemical, Thermal, and Friction Performance