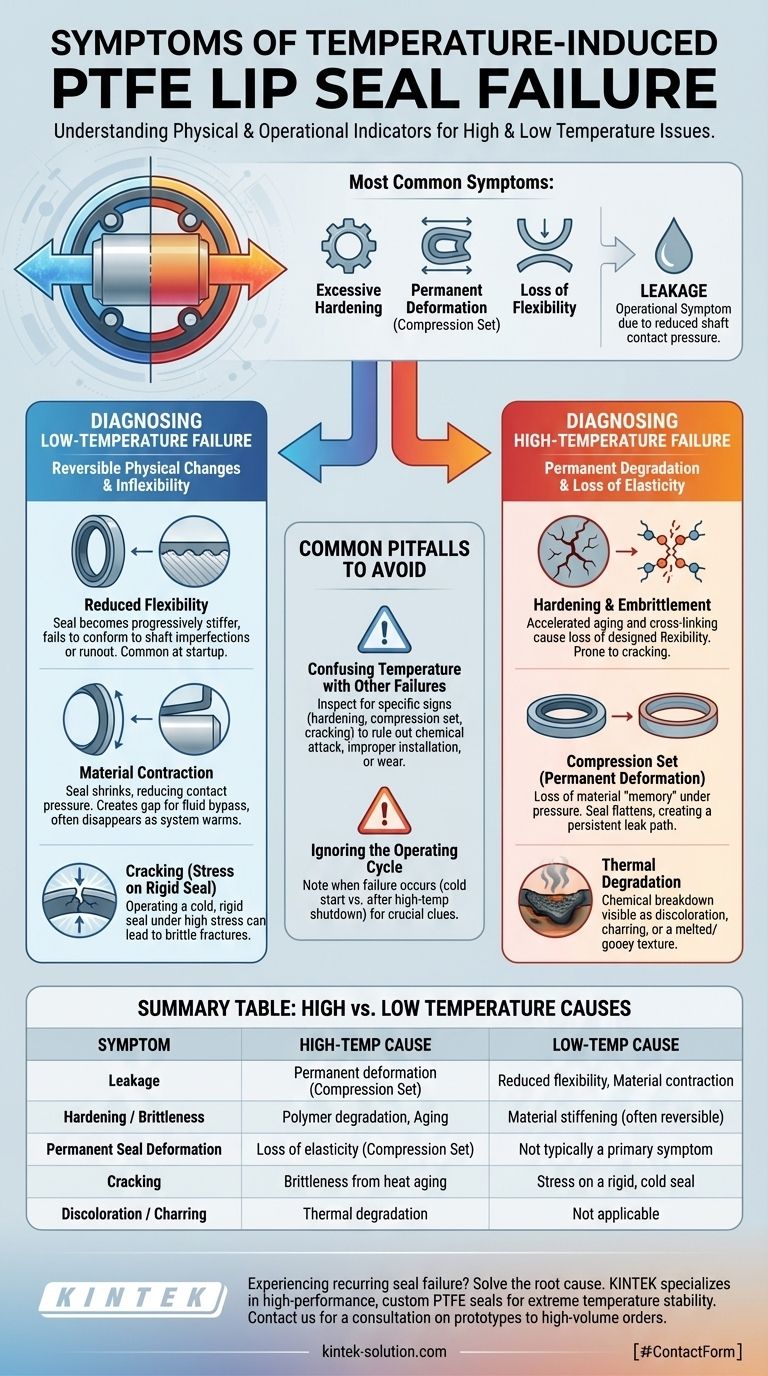

The most common symptoms of temperature-induced PTFE lip seal failure are physical changes to the seal itself, such as excessive hardening, permanent deformation (compression set), or a noticeable loss of flexibility. These material changes directly result in the operational symptom of leakage, as the seal can no longer maintain the necessary contact pressure against the shaft.

The core challenge in diagnosis is understanding that both high and low temperatures cause failure, but they do so through different mechanisms. Recognizing the distinct physical evidence of heat versus cold is the key to identifying the root cause of the failure.

Diagnosing High-Temperature Failure

When a PTFE seal operates above its designed temperature limit, the material begins to break down. This degradation is permanent and presents clear physical symptoms.

Hardening and Embrittlement

Extreme heat accelerates the aging of the seal material. The polymer chains can break down or cross-link in unintended ways, causing the seal to lose its designed flexibility and become hard or brittle. A brittle seal is prone to cracking under normal operational pressure and vibration.

Compression Set (Permanent Deformation)

Heat causes the seal material to lose its "memory" or elasticity. Under constant pressure, a hot seal will deform to fit the space and will not spring back to its original shape when the system cools. This permanent flattening, known as a compression set, creates a gap and a persistent leak path.

Thermal Degradation

In cases of severe overheating, the seal material will show signs of chemical breakdown. This can appear as discoloration, charring, or a melted or gooey texture on the seal's surface, providing definitive evidence of excessive temperature exposure.

Diagnosing Low-Temperature Failure

Operating below the seal's minimum temperature rating causes physical changes that are often, but not always, reversible once the seal returns to its normal operating temperature.

Reduced Flexibility

As temperatures drop, PTFE materials become progressively stiffer. A rigid seal cannot conform to microscopic imperfections on the shaft surface or respond to dynamic runout (shaft wobble), leading to leakage, especially during startup.

Material Contraction

All materials shrink in the cold. A seal can contract enough to pull away from the shaft, slightly reducing the contact pressure at the sealing lip. This can create a small gap, allowing fluid to bypass the seal, a problem often noticed during cold starts that may disappear as the equipment warms up.

Common Pitfalls to Avoid

Diagnosing seal failure requires careful observation, as symptoms can be misleading if not considered in context.

Confusing Temperature with Other Failures

Leakage is a universal symptom of any seal failure. It is critical to inspect the failed seal for the specific physical signs—hardening, compression set, or cracking—to confirm that temperature is the root cause, rather than chemical attack, improper installation, or abrasive wear.

Ignoring the Operating Cycle

A seal may only leak during specific phases of operation, such as a cold startup or immediately after a high-temperature shutdown. Understanding when the failure occurs provides crucial clues to whether the problem is related to low-temperature inflexibility or high-temperature deformation.

A Practical Checklist for Inspection

Use this guide during a visual inspection to determine the most likely cause of failure.

- If your primary issue is leakage during cold starts: Suspect low-temperature embrittlement, as the seal is too stiff to conform to the shaft until the system generates operational heat.

- If you observe a permanently flattened, hard, or discolored seal: This points directly to high-temperature exposure causing an irreversible compression set or material degradation.

- If the seal is cracked or shows signs of breaking apart: This indicates embrittlement, which can be caused by either extreme heat aging or operating a cold, rigid seal under high stress.

By correctly identifying these temperature-induced symptoms, you can move beyond simple replacement to address the root cause of the failure within your system.

Summary Table:

| Symptom | High-Temperature Cause | Low-Temperature Cause |

|---|---|---|

| Leakage | Permanent deformation (compression set) | Reduced flexibility and material contraction |

| Hardening / Brittleness | Polymer degradation and aging | Material stiffening (often reversible) |

| Permanent Seal Deformation | Loss of elasticity (compression set) | Not typically a primary symptom |

| Cracking | Brittleness from heat aging | Stress on a rigid, cold seal |

| Discoloration / Charring | Thermal degradation | Not applicable |

Experiencing recurring seal failure? Don't just replace the part—solve the root cause. KINTEK specializes in high-performance, custom-fabricated PTFE seals designed for extreme temperature stability in the semiconductor, medical, laboratory, and industrial sectors. Our precision manufacturing ensures your seals perform reliably, preventing downtime and leakage.

Contact us today for a consultation on custom PTFE components, from prototypes to high-volume orders. Let our expertise enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions