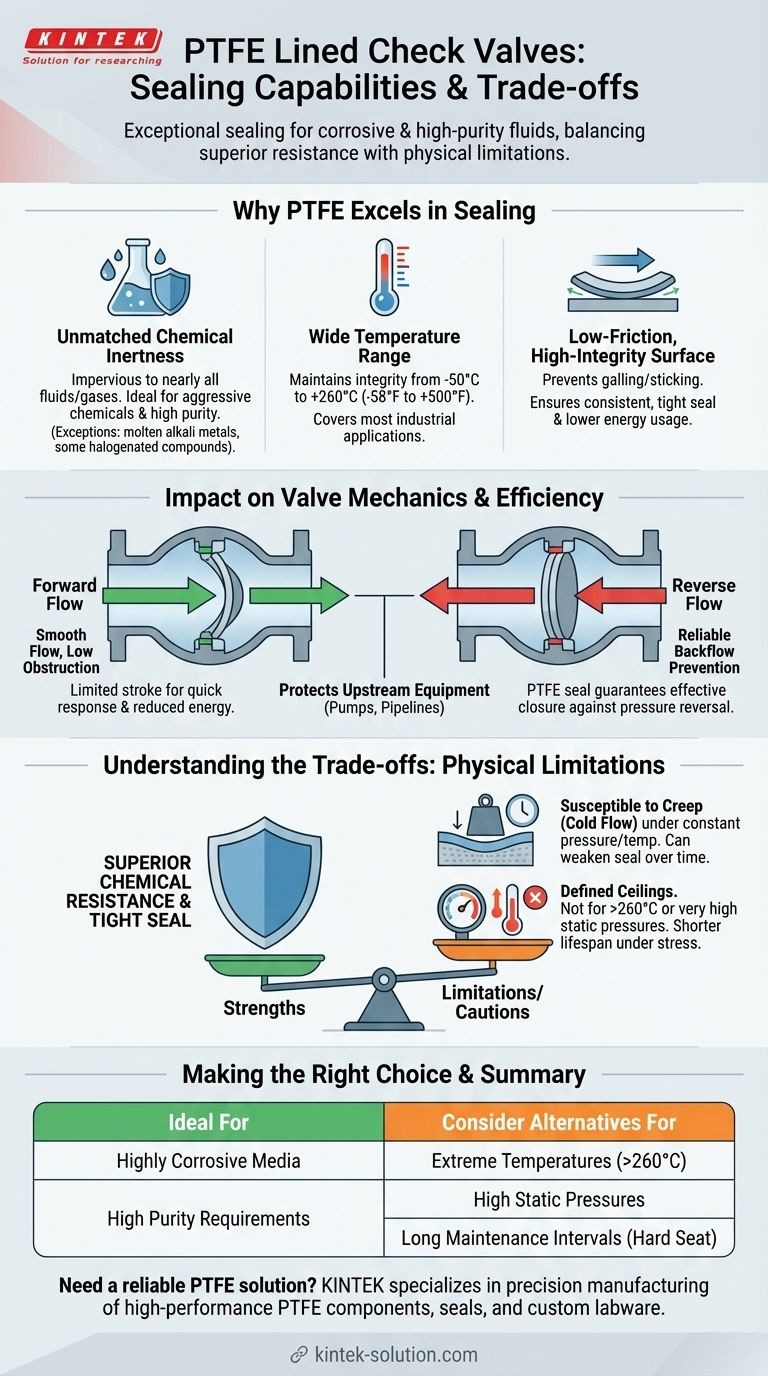

At their core, PTFE lined check valves offer exceptional sealing capabilities, particularly in applications involving corrosive or high-purity fluids. Their performance stems directly from the unique properties of Polytetrafluoroethylene (PTFE), which creates a chemically inert and low-friction sealing surface that is effective against a vast range of fluids and gases.

The decision to use a PTFE lined check valve is a trade-off. You gain superior chemical resistance and a tight seal at the cost of being mindful of PTFE's specific physical limitations, such as its susceptibility to creep under pressure and its defined temperature ceiling.

Why PTFE Excels in Sealing Performance

The effectiveness of a PTFE lined check valve is rooted in the material science of its lining and sealing components, such as O-rings and V-ring packing.

Unmatched Chemical Inertness

PTFE is famously non-reactive. It is impervious to nearly all fluids and gases, making it an ideal choice for aggressive chemical dosing systems or where media purity is critical.

Only a few substances, like molten alkaline metals and certain halogenated compounds, can degrade PTFE.

Wide Operational Temperature Range

PTFE seals maintain their integrity across a broad temperature spectrum, typically from -50°C to +260°C (-58°F to +500°F).

This range covers the majority of industrial fluid handling applications, from cryogenic services to low-pressure steam.

Low-Friction, High-Integrity Surface

The smooth, low-friction surface of PTFE allows valve components to move freely and seat properly without galling or sticking. This ensures a tight, consistent seal is formed every time the valve closes.

This property also contributes to lower energy usage, as less force is required to operate the valve mechanism against the seal.

How Sealing Impacts Valve Mechanics

The sealing material directly influences the valve's overall design and efficiency, helping it protect sensitive upstream equipment like pumps and pipelines.

Preventing Damaging Reverse Flow

The primary function of a check valve is to permit flow in one direction only. The reliability of the PTFE seal is what guarantees the valve can effectively prevent backflow when pressure reverses.

Efficient Flow and Quick Response

Many PTFE lined check valves feature a limited valve stroke. This means the internal components only have to travel a short distance to open or close.

This design minimizes obstruction to the fluid, enabling smoother flow and reducing the energy required by the pumping system. It also allows the valve to close more quickly to prevent backflow surges.

Understanding the Trade-offs: Physical Limitations of PTFE

While its chemical resistance is nearly absolute, PTFE's physical properties present limitations that are critical to understand for long-term reliability.

The Challenge of Creep (Cold Flow)

The most significant drawback of PTFE is its susceptibility to creep, or "cold flow." Under constant pressure and temperature, the material can slowly deform over time.

This deformation can weaken the integrity of a gasket or seal, potentially leading to leaks. This is why hard seal valves are sometimes chosen for high-pressure applications, even though their initial sealing performance is generally weaker.

Defined Temperature and Pressure Ceilings

While the temperature range is wide, other materials can handle higher temperatures. If your application exceeds 260°C (500°F), PTFE is not a suitable choice.

Similarly, the tendency to creep makes PTFE less ideal for applications with very high, static pressures where a rigid metal seat would be more durable.

A Shorter Lifespan in Demanding Conditions

Because of factors like creep and aging, PTFE seals can have a shorter operational lifespan compared to metal-seated valves, especially under continuous mechanical stress.

This makes it crucial to consider maintenance schedules and the accessibility of the valve within the system.

Making the Right Choice for Your System

Your selection must be based on the specific demands of your operational environment.

- If your primary focus is handling highly corrosive media or ensuring high purity: A PTFE lined check valve is often the best and most reliable choice due to its unparalleled chemical inertness.

- If your primary focus is extreme temperature (above 260°C), high static pressure, or maximizing time between maintenance: You must carefully evaluate the risk of creep and consider a hard-seated valve as a more durable alternative.

Ultimately, selecting a PTFE lined check valve is a strategic decision that balances its superb chemical resistance against its specific physical limitations.

Summary Table:

| Feature | Performance / Limitation |

|---|---|

| Chemical Resistance | Impervious to nearly all fluids and gases |

| Temperature Range | -50°C to +260°C (-58°F to +500°F) |

| Primary Limitation | Susceptible to creep (cold flow) under pressure |

| Key Advantage | Ideal for corrosive media and high-purity applications |

Need a reliable PTFE lined check valve for your demanding application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Our expertise ensures your valves deliver the tight seal and exceptional chemical resistance required in semiconductor, medical, laboratory, and industrial processes.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a solution tailored to your specific pressure, temperature, and media challenges.

Contact us today to discuss your project requirements and let our experts help you select or design the perfect PTFE solution. #ContactForm

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability