No, not all PTFE gasket sheets are suitable for food applications. The critical factor is whether the material is 100% pure PTFE or a "filled" grade. Only virgin PTFE is inherently inert and safe for direct food contact, as additives in filled grades can leach into and contaminate the product.

The suitability of a PTFE gasket for food applications hinges on a single, crucial detail: its composition. While pure, virgin PTFE is FDA-compliant and safe, filled PTFE grades—which contain additives to enhance mechanical properties—are not, as the fillers can pose a contamination risk.

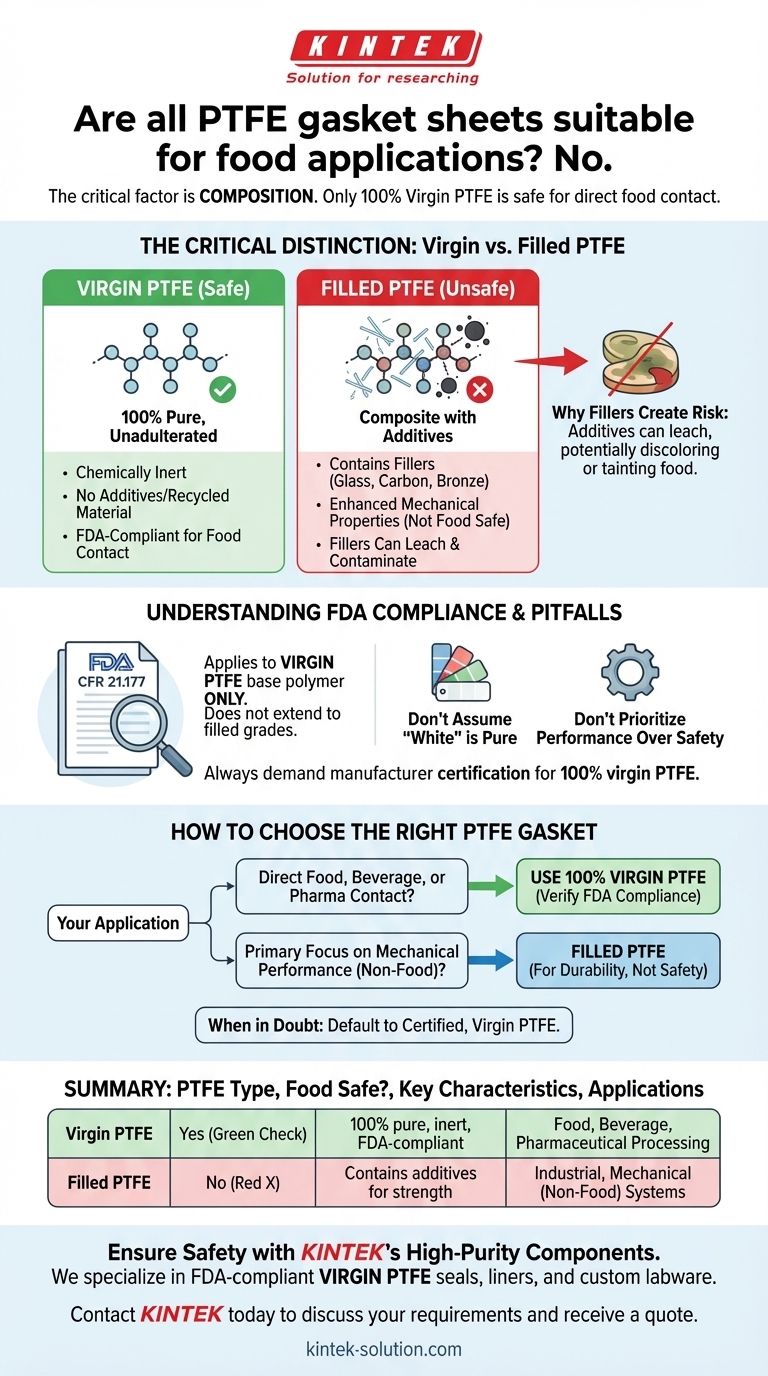

The Critical Distinction: Virgin vs. Filled PTFE

Understanding the difference between these two categories is the key to ensuring safety and compliance in any food-processing environment. They are not interchangeable when food contact is a requirement.

What is Virgin PTFE?

Virgin PTFE is the pure, unadulterated form of polytetrafluoroethylene. It contains no additives or recycled material.

Because of its chemical inertness, it does not react with or impart any taste or color to materials it touches, making it the default choice for food, beverage, and pharmaceutical applications. This is the grade that complies with FDA regulations.

What is Filled PTFE?

Filled PTFE is a composite material where additives like glass, carbon, or bronze are blended into the PTFE base.

These fillers are added to enhance specific mechanical properties, such as improving wear resistance, increasing compressive strength, or reducing creep under load. While superior for many industrial applications, these enhancements come at the cost of food safety.

Why Fillers Create a Food Safety Risk

The additives used in filled PTFE are typically not approved for food contact.

These fillers can leach out of the gasket material over time, potentially discoloring or tainting the food product. This makes filled PTFE gaskets entirely unsuitable and non-compliant for any application involving direct contact with consumables.

Understanding FDA Compliance

A general "PTFE is FDA approved" statement can be dangerously misleading. The approval is specific to the base polymer and does not automatically extend to all variations.

The Role of FDA CFR 21.177

The relevant regulation is often cited as FDA CFR 21.177.2600. This standard applies to rubber articles intended for repeated use, and the principles extend to polymers like pure PTFE.

However, this compliance applies specifically to the virgin PTFE polymer itself, not to the additives found in filled grades.

The Importance of Manufacturer Certification

Never assume a PTFE gasket sheet is food-safe. Always request documentation from the supplier or manufacturer.

This documentation should explicitly state that the specific product you are purchasing is made from 100% virgin PTFE and complies with the necessary FDA regulations for food contact.

Common Pitfalls to Avoid

Choosing the wrong material can lead to product contamination and regulatory failure. Being aware of common misconceptions is essential.

The Lure of Enhanced Performance

Engineers may be tempted to select a filled PTFE for its superior mechanical strength or wear characteristics, especially in a demanding application.

This is a critical error in a food-grade system. The performance gains of a filled gasket are irrelevant if it renders the final product unsafe. Food safety must always be the primary consideration.

Assuming All "White" PTFE is Pure

While virgin PTFE is characteristically white, some filled grades also appear white.

You cannot determine if a PTFE sheet is virgin or filled by visual inspection alone. Verification through manufacturer specifications is the only reliable method.

How to Choose the Right PTFE Gasket

Your final choice must be dictated by the application's specific requirements, with safety being the first priority.

- If your primary focus is direct food, beverage, or pharmaceutical contact: You must use a gasket sheet made from 100% virgin PTFE and verify its FDA compliance with the supplier.

- If your primary focus is mechanical performance in a non-food system: A filled PTFE grade is likely the better choice, offering superior durability and resistance to wear and compression.

- If you are ever in doubt: Always default to certified, virgin PTFE to eliminate any risk of contamination or non-compliance.

Ultimately, ensuring the safety of your application begins with demanding precise material verification.

Summary Table:

| PTFE Type | Food Safe? | Key Characteristics | Common Applications |

|---|---|---|---|

| Virgin PTFE | Yes | 100% pure polymer, inert, FDA-compliant | Food, beverage, pharmaceutical processing |

| Filled PTFE | No | Contains additives (glass, carbon, etc.) for strength | Industrial, mechanical (non-food) systems |

Ensure your food processing equipment is safe and compliant with precision-made PTFE components from KINTEK.

Choosing the wrong gasket material can lead to product contamination and regulatory failure. We specialize in manufacturing high-purity, FDA-compliant virgin PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and food industries.

Our expertise in custom fabrication, from prototypes to high-volume orders, guarantees you receive components that meet the strictest safety and performance standards. Don't risk your product's integrity.

Contact KINTEK today to discuss your specific requirements and receive a quote for reliable, food-safe PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- When should PTFE bellows be chosen over other materials? Maximize System Purity and Chemical Resistance

- What are the key properties of PTFE as an O-ring material? Maximize Performance in Harsh Environments

- How does the PTFE sliding pad function smoothly? An Inside Look at Low-Friction Engineering

- What are the friction properties of extruded PTFE rods? Achieve Ultra-Low Friction for Your Critical Applications

- What are alternatives to Teflon sheets for heat press? Parchment Paper vs. Silicone vs. Teflon

- What is the coefficient of friction for PTFE O-Rings and why is it beneficial? Achieve Smooth, Low-Friction Performance

- What types of fasteners can be made from PTFE? A Guide to Chemical-Resistant, Low-Friction Components

- What are the different types of PTFE seals? Choose the Right Seal for Your Application