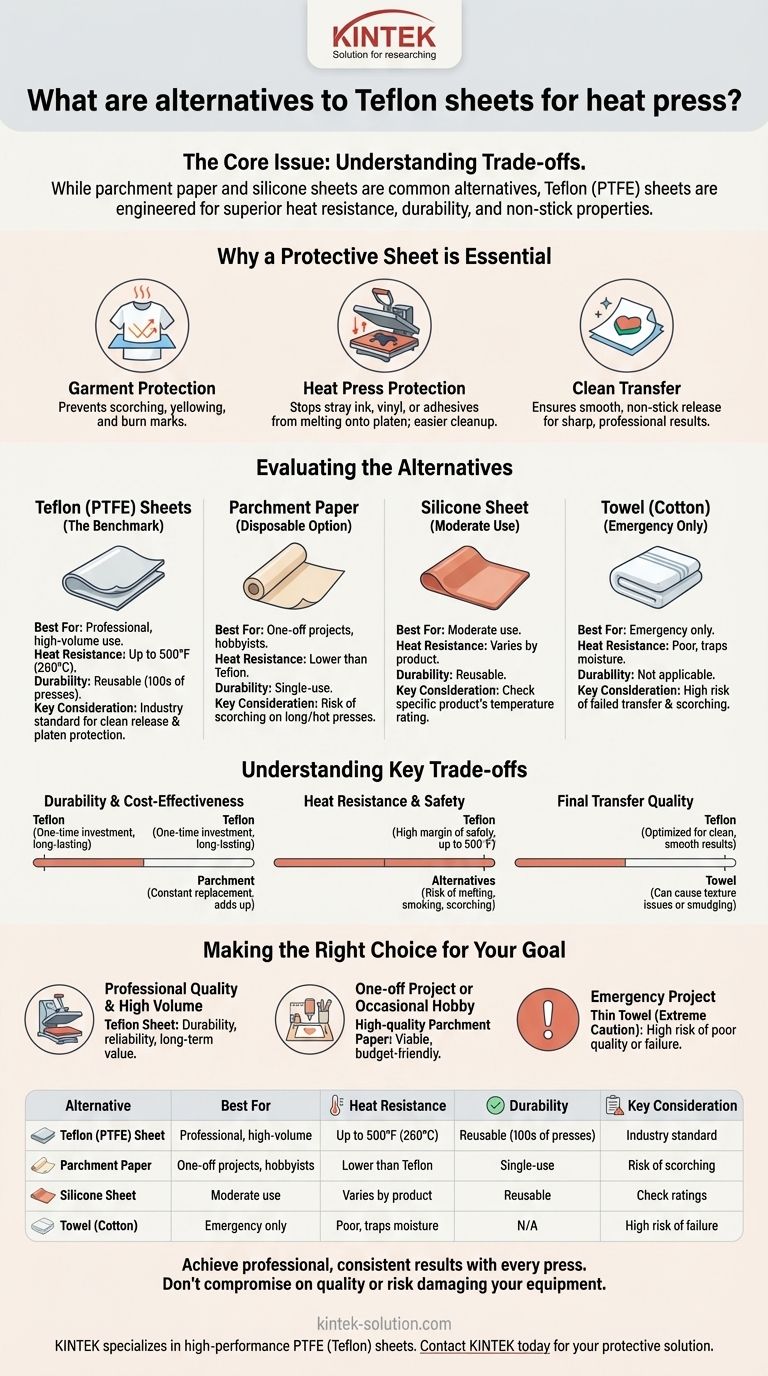

The most common alternatives to a Teflon sheet for a heat press are parchment paper and silicone sheets. While these can work in a pinch, a Teflon sheet is specifically engineered for this task, offering superior heat resistance, durability, and non-stick properties that protect both your garment and your equipment.

The core issue isn't just finding a substitute, but understanding the trade-offs. While alternatives like parchment paper are accessible, they lack the reusability and high heat tolerance of a Teflon sheet, which is designed to ensure consistent, professional-quality results over time.

Why a Protective Sheet is Essential

A protective sheet is not just an accessory; it's a critical component in the heat transfer process. It acts as a protective barrier between the hot upper platen of your press and your transfer design.

Protects Your Garment

The sheet shields your fabric from direct, intense heat. This prevents scorching, yellowing, and burn marks, especially on sensitive materials.

Protects Your Heat Press

It creates a non-stick barrier that stops stray ink, vinyl, or adhesives from melting onto the heat platen. This prevents contamination on your next project and makes cleanup significantly easier.

Ensures a Clean Transfer

The smooth, non-stick surface ensures that your transfer releases cleanly without smudging or sticking. This is crucial for achieving sharp, professional-looking results.

Evaluating the Alternatives

Each protective material offers a different balance of performance, durability, and cost. Understanding these differences is key to choosing the right one for your needs.

The Benchmark: Teflon (PTFE) Sheets

Teflon sheets are the industry standard for a reason. They are highly durable, can be reused hundreds of times, and can withstand temperatures up to 500°F (260°C) without degrading. Their slick surface guarantees a clean release.

The Disposable Option: Parchment Paper

Parchment paper is a common household item that can be used for heat pressing. It's inexpensive and readily available, making it a decent choice for hobbyists or one-off projects.

However, it's far less durable than Teflon and is generally considered a single-use item. It also has a lower heat tolerance, increasing the risk of scorching on long or high-temperature presses.

The Last Resort: A Towel

A thin cotton towel can be used in an emergency, but it is not recommended. It does not provide a non-stick surface and can leave a textured impression on your design.

More importantly, a towel distributes heat unevenly and can trap moisture, significantly increasing the risk of a failed transfer or a scorched garment.

Understanding the Key Trade-offs

Choosing an alternative to Teflon is a matter of balancing cost against performance and safety.

Durability and Cost-Effectiveness

A Teflon sheet is a one-time investment that lasts for a very long time, making it the most cost-effective solution for anyone doing frequent pressing. Parchment paper, while cheap per sheet, requires constant replacement, and its cost can add up over time.

Heat Resistance and Safety

Teflon's high heat resistance provides a crucial margin of safety. Using materials not designed for high temperatures, like some wax papers or a towel, can lead to melting, smoking, or scorching, ruining your project and potentially damaging your press.

Final Transfer Quality

The perfectly smooth, non-stick surface of Teflon is optimized for clean results. Parchment paper is a close second, but other alternatives like towels can interfere with the transfer, causing texture issues or smudging.

Making the Right Choice for Your Goal

Your choice of protective sheet should align directly with the needs of your project.

- If your primary focus is professional quality and high volume: A Teflon sheet is the only logical choice for its durability, reliability, and long-term value.

- If your primary focus is a one-off project or occasional hobby use: High-quality parchment paper is a viable and budget-friendly alternative.

- If your primary focus is getting a project done in an emergency: A thin towel can be used with extreme caution, but you must accept the high risk of a poor-quality or failed transfer.

Ultimately, using the right tool for the job ensures your creative vision is realized without compromise.

Summary Table:

| Alternative | Best For | Heat Resistance | Durability | Key Consideration |

|---|---|---|---|---|

| Teflon (PTFE) Sheet | Professional, high-volume use | Up to 500°F (260°C) | Reusable (100s of presses) | Industry standard for clean release & platen protection |

| Parchment Paper | One-off projects, hobbyists | Lower than Teflon | Single-use | Risk of scorching on long/hot presses |

| Silicone Sheet | Moderate use | Varies by product | Reusable | Check specific product's temperature rating |

| Towel (Cotton) | Emergency only | Poor, traps moisture | Not applicable | High risk of failed transfer & scorching |

Achieve professional, consistent results with every press. Don't compromise on quality or risk damaging your equipment with subpar alternatives.

KINTEK specializes in manufacturing high-performance, durable PTFE (Teflon) sheets and components engineered for the demands of heat pressing and other specialized industrial applications. Our sheets offer superior heat resistance and non-stick properties to protect your garments and equipment, ensuring a flawless transfer every time.

Whether you need a standard size or a custom-fabricated solution, we provide precision production from prototypes to high-volume orders.

Contact KINTEK today to discuss your needs and get the right protective solution for your heat press.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- What temperature range can PTFE bushes withstand? From Cryogenic -200°C to High-Heat 260°C

- What makes CNC machined PTFE suitable for aerospace and space exploration applications? Unmatched Reliability in Extreme Environments

- How do ePTFE gaskets form a seal when installed? By Flowing to Create a Perfect Seal

- How does PTFE's soft nature affect surface finish quality during machining? Mastering the Slice, Not Tear, Process

- How is Teflon used in the semiconductor industry? Essential for High-Purity Manufacturing

- How does the design of a Teflon lip seal accommodate PTFE's stiffness? Leverage Geometry for Flexibility

- Why is PTFE considered chemically inert, and why is this beneficial for bushings? Ensure Reliability in Harsh Chemical Environments