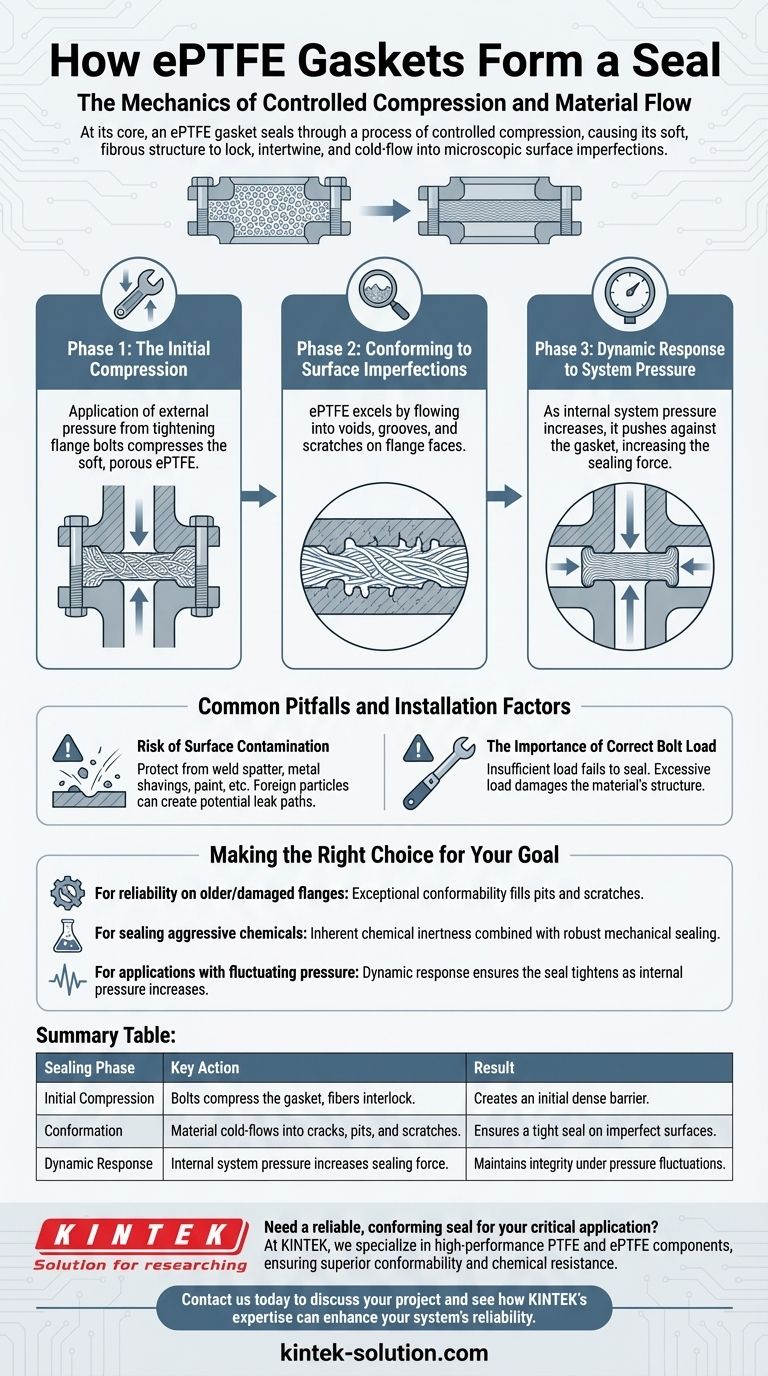

At its core, an ePTFE gasket seals through a process of controlled compression and material flow. When tightened between flanges, the soft, fibrous structure of expanded Polytetrafluoroethylene (ePTFE) is compressed, causing its internal fibers to lock and intertwine. This action forces the material to cold-flow into every microscopic crack, pit, and irregularity on the sealing surfaces, creating a highly effective and conforming physical barrier.

The unique value of an ePTFE gasket isn't just that it compresses; it's that it flows under pressure to create a perfect mirror image of the flange surfaces, while its internal structure maintains a dynamic, responsive seal even as system conditions change.

The Mechanics of the ePTFE Seal

To understand the effectiveness of ePTFE, we must look at the sequence of events that occurs during and after installation. The seal is not a static event but a dynamic process.

The Initial Compression Phase

The sealing process begins with the application of external pressure from tightening the flange bolts. This initial load is the catalyst for the entire sealing action.

The force compresses the soft, porous ePTFE material, causing the internal fibers to densify and interlock. This creates the initial, solid barrier that prevents leakage at low pressures.

Conforming to Surface Imperfections

This is where ePTFE truly excels. Unlike harder gaskets that require pristine, flat surfaces, ePTFE’s structure is designed to be highly conformable.

As the fibers compress, the material essentially flows into voids, grooves, and scratches on the flange faces. This adaptability ensures a tight and secure seal even on older, worn, or imperfect surfaces that other gaskets might fail to seal.

Dynamic Response to System Pressure

An ePTFE gasket provides more than just a passive seal. The material exhibits excellent rebound and flexibility.

This means that as the internal pressure of the system increases, it pushes against the gasket, actually increasing the sealing force. This dynamic response helps the gasket adapt to pressure fluctuations and maintain its integrity under load.

Common Pitfalls and Installation Factors

While highly effective, the unique properties of ePTFE also introduce specific handling and installation requirements. Ignoring these can compromise the seal's integrity.

Risk of Surface Contamination

The soft, porous nature of ePTFE makes it susceptible to contamination before it is fully compressed.

It is critical to protect the gasket material from weld spatter, metal shavings, paint, and other debris during installation. Any foreign particle can become embedded in the surface and create a potential leak path.

The Importance of Correct Bolt Load

The entire sealing mechanism depends on achieving the correct initial compression.

Insufficient bolt load will fail to compress the fibers enough to create a dense seal and flow into surface imperfections. Conversely, excessive bolt load can crush the material beyond its effective limit, damaging its internal structure and ability to respond dynamically to pressure changes.

Making the Right Choice for Your Goal

Understanding this mechanism allows you to apply ePTFE where its strengths will have the greatest impact.

- If your primary focus is reliability on older or damaged flanges: The exceptional conformability of ePTFE is its key advantage, as it perfectly fills pits and scratches to prevent leaks where other gaskets might fail.

- If your primary focus is sealing aggressive chemicals: The inherent chemical inertness of PTFE, combined with its robust mechanical sealing, makes it an ideal choice for a wide range of corrosive media.

- If your primary focus is applications with fluctuating pressure: The dynamic response of ePTFE ensures the seal tightens as internal pressure increases, providing an added layer of safety and reliability.

Ultimately, understanding how ePTFE flows and conforms is key to leveraging its power for a dependable, long-lasting seal.

Summary Table:

| Sealing Phase | Key Action | Result |

|---|---|---|

| Initial Compression | Bolts compress the gasket, causing fibers to interlock. | Creates an initial dense barrier. |

| Conformation | Material cold-flows into cracks, pits, and scratches on flanges. | Ensures a tight seal on imperfect surfaces. |

| Dynamic Response | Internal system pressure increases the sealing force. | Maintains integrity under pressure fluctuations. |

Need a reliable, conforming seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE and ePTFE components, including seals, gaskets, liners, and custom labware. Our precision production ensures your gaskets deliver superior conformability and chemical resistance for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or a high-volume order, we can fabricate the perfect sealing solution for your unique requirements.

Contact us today to discuss your project and see how KINTEK's expertise can enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How should PTFE laminated bearing pads be installed? A Guide to Precision Installation for Bridge Movement

- What are the characteristics of Polytetrafluoroethylene (PTFE) with Carbon-Graphite Fill for aqueous fluid media? Enhance Sealing Performance

- What are the disadvantages of PTFE ball valves? Key Limitations in Chemical & Industrial Applications

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface

- What is the function of PFA and PTFE lined check valves in chemical plants? Prevent Corrosive Backflow and Protect Equipment

- What industries commonly use PTFE valves and components? Essential for Chemical & Purity Applications

- What industries commonly use PTFE bushings? Critical Applications in Chemical, Automotive, and Medical

- What are the benefits of carbon fiber filled PTFE? Boost Strength, Wear & Heat Dissipation