At its core, CNC machined Polytetrafluoroethylene (PTFE) is a cornerstone material for aerospace and space exploration because it remains exceptionally stable and reliable in environments that would cause most other materials to fail catastrophically. Its suitability is not due to a single trait, but a powerful combination of extreme thermal stability, near-total chemical inertness, and an incredibly low coefficient of friction. This makes it indispensable for components where failure is not an option.

The true value of PTFE in aerospace is its predictable performance under unpredictable conditions. It provides a rare guarantee of reliability, whether exposed to the vacuum and cryogenic cold of deep space or the aggressive chemicals and high temperatures of propulsion systems.

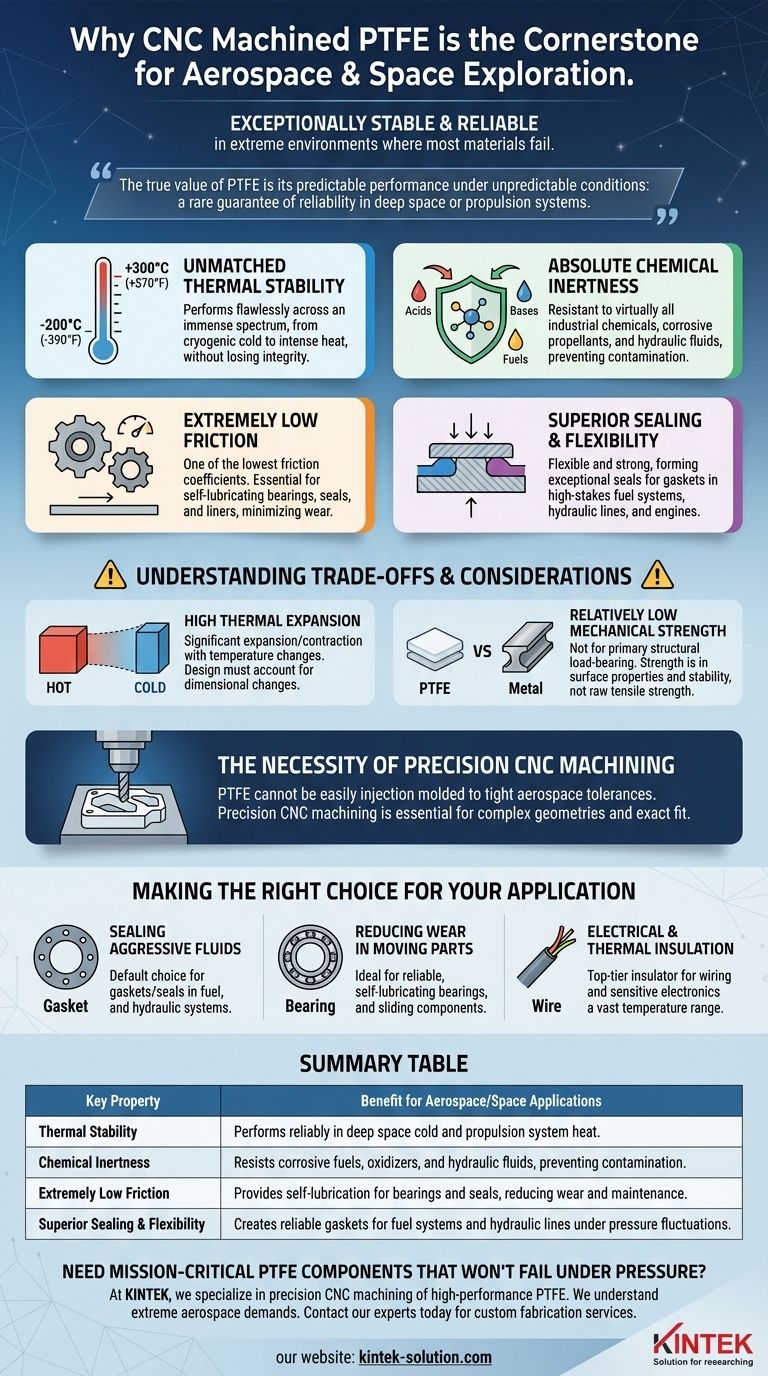

Why PTFE Excels in Extreme Environments

The harsh conditions of aerospace demand materials that can perform without degradation. PTFE's unique molecular structure gives it a set of properties that seem almost purpose-built for these challenges.

Unmatched Thermal Stability

PTFE operates flawlessly across an immense temperature spectrum, typically from -200°C (-390°F) to +300°C (+570°F).

This means a single PTFE component can endure the deep cold of space and the intense heat generated by engines or atmospheric re-entry without losing its structural integrity or critical properties.

Absolute Chemical Inertness

PTFE is famously resistant to virtually all industrial chemicals, strong acids, and bases, including the highly corrosive propellants and hydraulic fluids used in spacecraft and aircraft.

This inertness is due to its molecular structure, where a helical carbon chain is completely sheathed by fluorine atoms. This robust atomic bond protects the material from chemical attack, preventing corrosion and contamination in critical fluid systems.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid material. This "slipperiness" is essential for components that move against each other.

In aerospace, this property is leveraged for self-lubricating bearings, seals, and liners. It minimizes wear and tear, reduces the need for maintenance, and ensures smooth operation for the lifetime of a mission.

Superior Sealing and Flexibility

The material is both flexible and strong enough to form exceptional seals. This quality makes it ideal for gaskets in high-stakes applications.

CNC machined PTFE gaskets are critical components in fuel systems, hydraulic lines, engines, and airframes, where they prevent dangerous leaks under fluctuating pressures and temperatures.

Understanding the Trade-offs and Considerations

While PTFE is a remarkable material, a true technical understanding requires acknowledging its limitations. These factors must be engineered around to ensure mission success.

High Coefficient of Thermal Expansion

One of the most critical considerations is PTFE's tendency to expand and contract significantly with temperature changes.

Engineers must account for this dimensional change in their designs. Failing to do so can lead to component stress, loss of sealing pressure, or outright mechanical failure when moving between extreme hot and cold environments.

Relatively Low Mechanical Strength

Compared to metals or advanced composites, pure PTFE is a relatively soft material. It is not suitable for primary structural components that bear heavy loads.

Its strength lies in its surface properties and stability, not its raw tensile or compressive strength. It is a specialist material used for seals, insulators, and linings, not for building the chassis of a rover.

The Necessity of Precision Machining

PTFE's unique properties also make it a material that cannot be easily injection molded to the tight tolerances required by aerospace.

Precision CNC machining is therefore essential. This process allows for the creation of complex geometries with the exacting dimensions needed for components to fit and function perfectly within larger, mission-critical assemblies.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision based on solving a specific environmental challenge. Your primary goal will determine how you leverage its properties.

- If your primary focus is sealing aggressive fluids: PTFE's chemical inertness makes it the default choice for gaskets and seals in fuel, oxidizer, and hydraulic systems.

- If your primary focus is reducing wear in moving parts: Its low-friction surface is ideal for creating reliable, self-lubricating bearings, liners, and sliding components.

- If your primary focus is electrical and thermal insulation: Its stability across a vast temperature range and excellent dielectric properties make it a top-tier insulator for wiring and sensitive electronics.

Understanding both the profound strengths and the specific limitations of PTFE is the key to designing resilient and reliable aerospace systems.

Summary Table:

| Key Property | Benefit for Aerospace/Space Applications |

|---|---|

| Thermal Stability (-200°C to +300°C) | Performs reliably in deep space cold and propulsion system heat. |

| Chemical Inertness | Resists corrosive fuels, oxidizers, and hydraulic fluids, preventing contamination. |

| Extremely Low Friction | Provides self-lubrication for bearings and seals, reducing wear and maintenance. |

| Superior Sealing & Flexibility | Creates reliable gaskets for fuel systems and hydraulic lines under pressure fluctuations. |

Need mission-critical PTFE components that won't fail under pressure?

At KINTEK, we specialize in precision CNC machining of high-performance PTFE for the semiconductor, medical, laboratory, and industrial sectors. We understand the extreme demands of aerospace applications. Our custom fabrication services—from prototypes to high-volume orders—ensure your components meet the exacting standards for thermal stability, chemical resistance, and reliability that your projects demand.

Contact our experts today to discuss how our PTFE solutions can enhance the reliability and performance of your aerospace systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for seals and gaskets? Unlock Superior Sealing Performance

- How do PTFE expansion bellows benefit pulse dampeners? Achieve Superior Flow Stability and Corrosion Resistance

- What are the primary advantages of PTFE bellows? Achieve Unmatched Chemical & Thermal Resilience

- What are the basic types of PTFE Teflon gaskets? Choose the Right Seal for Your Application

- What are the recommended methods for preparing metal surfaces before bonding with PTFE? Achieve a Durable, High-Strength Bond

- Where are PTFE spherical balls typically used? Essential for Corrosive & Low-Friction Applications

- What techniques help minimize material smearing during Teflon machining? Achieve Clean, Precise PTFE Parts

- Why are PTFE seals preferred in press machinery in the pharmaceutical industry? Ensuring Purity and Performance