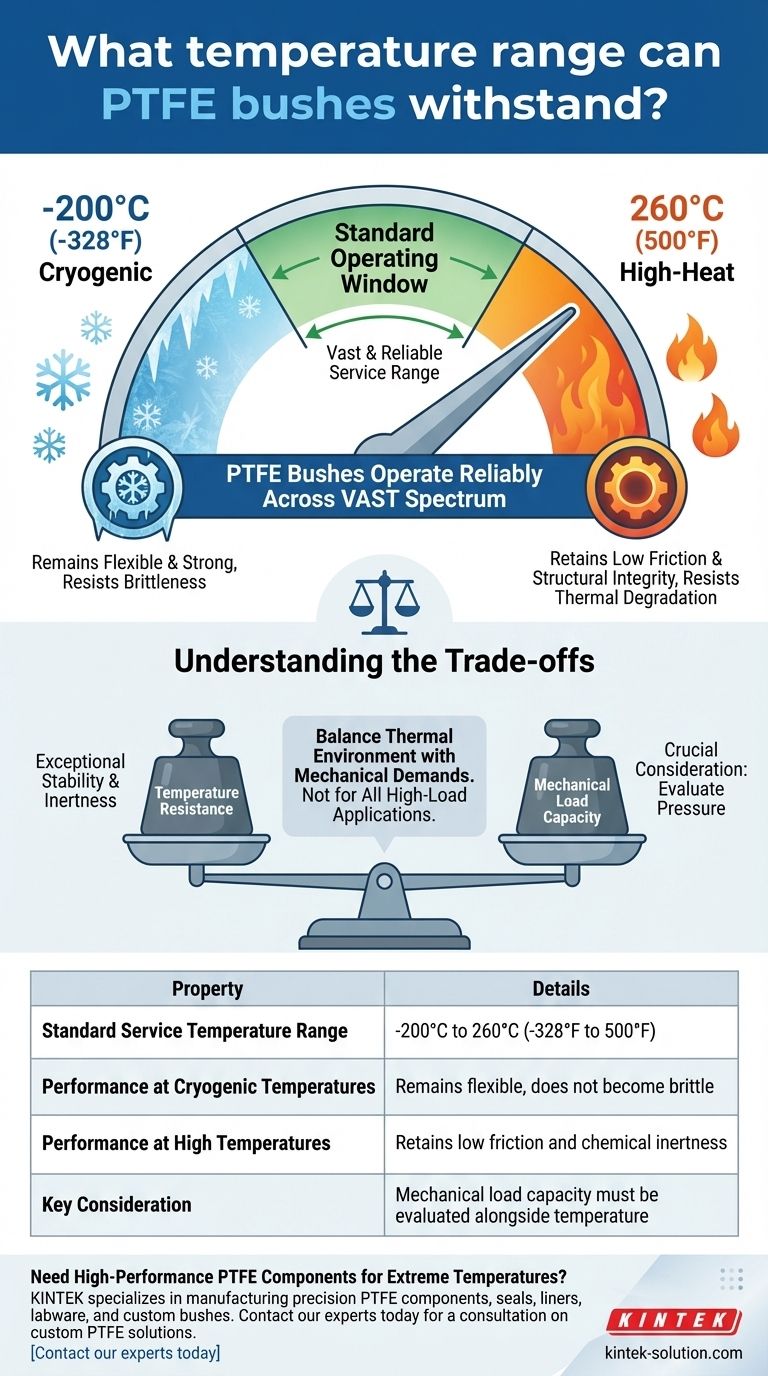

In short, PTFE bushes operate reliably within a vast temperature range. The generally accepted service temperature for Polytetrafluoroethylene (PTFE) is from -200°C (-328°F) up to 260°C (500°F). This remarkable thermal stability allows PTFE to maintain its key properties, such as low friction and chemical inertness, in both cryogenic and high-heat environments.

The critical takeaway is that while PTFE offers an exceptional temperature range, its suitability for a specific application depends equally on the mechanical load. Its thermal resilience must be considered alongside its limitations under high pressure.

The Basis of PTFE's Thermal Performance

The molecular structure of PTFE is responsible for its incredible thermal stability. It doesn't just survive extreme temperatures; it continues to perform its function reliably across the entire spectrum.

The Standard Operating Window

The established service temperature range for most PTFE components, including bushes, is -200°C to 260°C (-328°F to 500°F).

This range makes PTFE a premier choice for applications that experience significant temperature fluctuations or operate at constant extremes.

Performance in Cryogenic Conditions

At the low end of its range, PTFE does not become brittle like many other polymers. It maintains a useful degree of flexibility and strength, making it suitable for cryogenic applications where other materials would fail.

Performance in High-Heat Environments

At the upper limit of 260°C (500°F), PTFE resists thermal degradation. It retains its exceptionally low coefficient of friction and structural integrity, which is vital for bearing and bushing applications in industries like aerospace and automotive.

Understanding the Trade-offs

Selecting a material based on a single property can lead to design failure. While PTFE's thermal range is a key advantage, it is not a universal solution for every high-temperature application.

Temperature Resistance vs. Load Capacity

The primary trade-off with PTFE is its mechanical strength. It is a relatively soft material.

While it excels in low-friction scenarios, it may not be suitable for high-load or high-pressure applications where a metal bushing would be required. Always evaluate the specific load requirements of your design.

Variations in PTFE Grades

It's important to note that while the -200°C to 260°C range is standard for pure PTFE, slight variations can exist.

Different product types, such as O-rings, or filled grades of PTFE (e.g., glass-filled or carbon-filled) may have slightly different temperature ratings. Always consult the specific manufacturer's data sheet for the exact component you are considering.

Making the Right Choice for Your Goal

To select the right material, you must balance the thermal environment with the mechanical demands of the application.

- If your primary focus is thermal stability: PTFE is an excellent choice for applications with wide temperature swings, from cryogenic freezing to high operational heat.

- If your primary focus is high mechanical load: You must carefully verify that the load capacity of the PTFE bush is sufficient, and consider a metal or composite alternative if it is not.

- If your primary focus is both temperature and chemical resistance: PTFE's chemical inertness across its entire thermal range makes it an unparalleled choice for corrosive environments.

Ultimately, a successful design leverages PTFE's exceptional thermal properties while respecting its mechanical limitations.

Summary Table:

| Property | Details |

|---|---|

| Standard Service Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| Performance at Cryogenic Temperatures | Remains flexible, does not become brittle |

| Performance at High Temperatures | Retains low friction and chemical inertness |

| Key Consideration | Mechanical load capacity must be evaluated alongside temperature |

Need High-Performance PTFE Components for Extreme Temperatures?

PTFE's remarkable thermal stability from -200°C to 260°C makes it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. However, selecting the right component requires balancing temperature needs with mechanical load.

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom bushes. We help you navigate these trade-offs to ensure optimal performance and longevity for your specific environment, whether you need prototypes or high-volume production.

Let's discuss your application requirements. Contact our experts today for a consultation on custom PTFE solutions that deliver reliability across the entire temperature spectrum.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments