In the semiconductor industry, Teflon is primarily used as a critical material for fluid handling systems and process chamber components, valued for its extreme chemical inertness, high purity, and superior electrical insulation. It does not go into the silicon chip itself but is essential for the equipment that manufactures them, ensuring that the aggressive chemicals used in fabrication remain uncontaminated and do not corrode the machinery.

The core value of Teflon (PTFE) in semiconductor manufacturing is not as an ingredient in the final chip, but as an enabling material for the process. Its ability to handle highly corrosive chemicals without degrading or leaching impurities makes the entire high-purity fabrication environment possible.

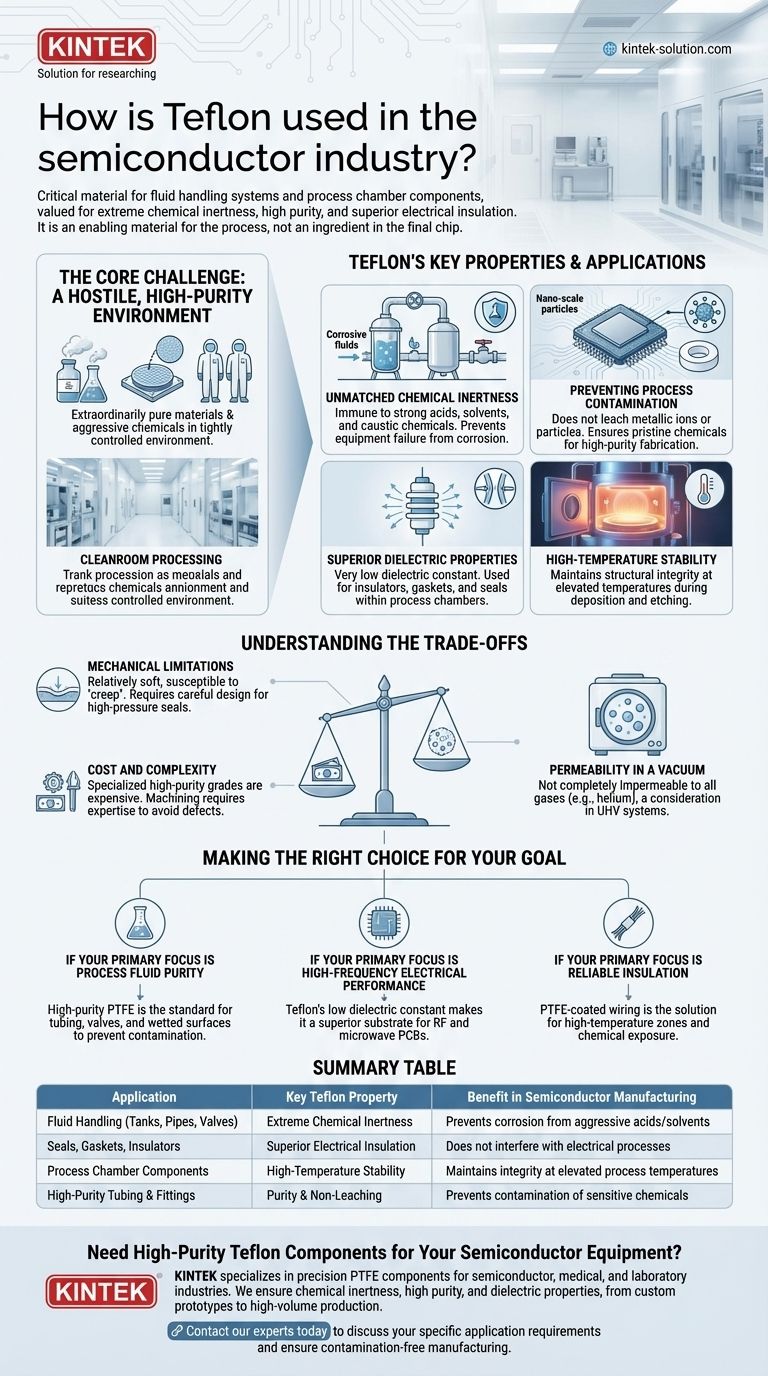

The Core Challenge: A Hostile, High-Purity Environment

The manufacturing of semiconductors is a study in extremes. It requires both extraordinarily pure materials and the use of some of the most aggressive and corrosive chemicals available, all within a tightly controlled environment.

Unmatched Chemical Inertness

Semiconductor fabrication relies on strong acids, solvents, and caustic chemicals to etch and clean silicon wafers. Teflon is virtually immune to all of them.

This property makes it the ideal material for lining tanks, pipes, valves, and fittings that transport these volatile fluids. It prevents equipment failure from corrosion.

Preventing Process Contamination

More importantly, Teflon’s inertness prevents it from leaching metallic ions or other particles into the process chemicals.

Even minuscule contamination can ruin an entire batch of microchips, where features are measured in nanometers. Using high-purity Teflon ensures the chemicals remain pristine from storage to the point of use.

Superior Dielectric Properties

Teflon is an exceptional electrical insulator with a very low dielectric constant.

This means it does not interfere with the electrical fields and processes occurring within fabrication equipment. It is often used for insulators, gaskets, and seals within process chambers and in test and measurement equipment.

High-Temperature Stability

Many fabrication steps, such as deposition and etching, occur at elevated temperatures.

Teflon maintains its structural integrity and chemical resistance at the high temperatures required by these processes, ensuring reliable performance without degradation.

Understanding the Trade-offs

While Teflon's properties are essential, engineers must also account for its limitations in specific applications. Its value is always a balance of its unique benefits against its inherent physical trade-offs.

Mechanical Limitations

Compared to metals or ceramics, Teflon is a relatively soft material. It can be susceptible to "creep" or cold flow, where the material slowly deforms under sustained pressure. This must be considered in the design of high-pressure seals and fittings.

Cost and Complexity

The specialized, high-purity grades of Teflon required for semiconductor applications are significantly more expensive than standard industrial polymers. Machining it also requires specific expertise to avoid creating surface imperfections that could trap contaminants.

Permeability in a Vacuum

While excellent as a liquid barrier, Teflon is not completely impermeable to all gases. In ultra-high vacuum (UHV) systems, very small molecules like helium can slowly permeate through the material, which can be a consideration in chamber design.

Making the Right Choice for Your Goal

Selecting Teflon is a strategic decision based on neutralizing specific environmental challenges inherent in electronics and semiconductor manufacturing.

- If your primary focus is process fluid purity: High-purity PTFE is the industry standard for tubing, valves, and wetted surfaces to prevent chemical contamination and equipment corrosion.

- If your primary focus is high-frequency electrical performance: Teflon's low dielectric constant makes it a superior substrate material for printed circuit boards (PCBs) used in RF and microwave applications.

- If your primary focus is reliable insulation: PTFE-coated wiring is the solution for cables that must operate in high-temperature zones or where exposure to harsh chemicals is a risk.

Ultimately, Teflon's role in the semiconductor world is that of an invisible guardian, protecting the hyper-sensitive manufacturing process from chemical and electrical interference.

Summary Table:

| Application | Key Teflon Property | Benefit in Semiconductor Manufacturing |

|---|---|---|

| Fluid Handling (Tanks, Pipes, Valves) | Extreme Chemical Inertness | Prevents corrosion from aggressive acids/solvents |

| Seals, Gaskets, Insulators | Superior Electrical Insulation | Does not interfere with electrical processes |

| Process Chamber Components | High-Temperature Stability | Maintains integrity at elevated process temperatures |

| High-Purity Tubing & Fittings | Purity & Non-Leaching | Prevents contamination of sensitive chemicals |

Need High-Purity Teflon Components for Your Semiconductor Equipment?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and custom parts) for the semiconductor, medical, and laboratory industries. We ensure the chemical inertness, high purity, and dielectric properties your processes demand, from custom prototypes to high-volume production.

Contact our experts today to discuss your specific application requirements and ensure contamination-free manufacturing.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts