To accommodate its inherent stiffness, a Teflon (PTFE) lip seal is engineered with a very thin and precisely shaped lip cross-section. This design transforms the rigid material into a flexible sealing element, allowing it to function like a spring that maintains constant, light-pressure contact against the shaft, even when minor misalignments or thermal expansion occurs.

The core design principle is not to fight the stiffness of PTFE, but to leverage it. By machining the material into a thin, flexible lip profile held within a rigid metal case, engineers create a seal that combines PTFE's chemical and thermal resistance with the dynamic sealing capability required for rotating shafts.

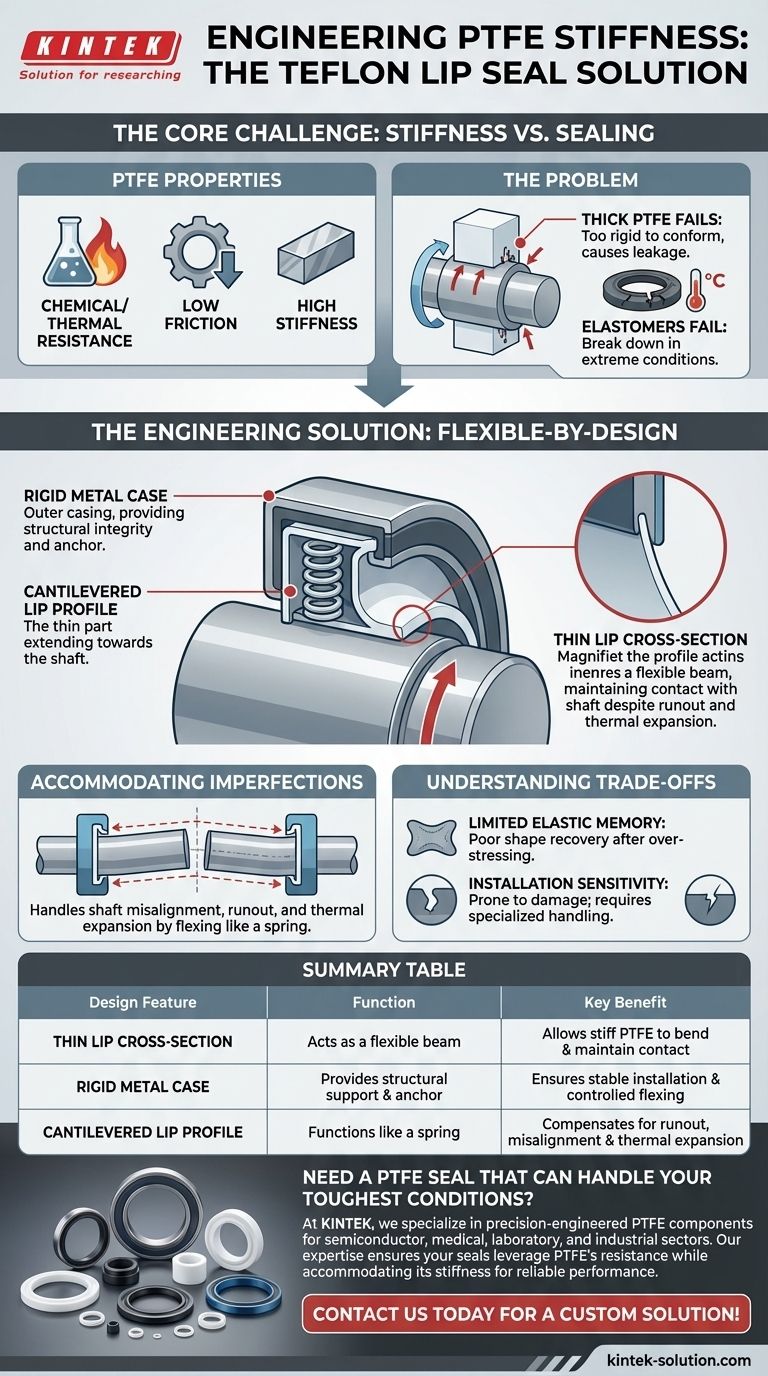

The Core Challenge: Stiffness vs. Sealing

To understand the design, we must first appreciate the material's properties. PTFE is chosen for its exceptional resistance to chemicals, wide temperature range, and extremely low friction. However, these benefits come with the significant challenge of high material stiffness and poor elasticity compared to traditional rubber seals.

Why a Simple Block of PTFE Fails

If you were to use a thick, simple ring of PTFE as a seal, it would fail almost immediately. Its rigidity would prevent it from conforming to the microscopic imperfections of a shaft's surface. It would be unable to follow any shaft runout or misalignment, leading to immediate and significant leakage.

The Limits of Elastomers

Traditional elastomer (rubber) seals are naturally flexible and resilient, making them easy to design with. However, they break down at the high temperatures, aggressive chemical environments, and high surface speeds where PTFE excels. The engineering goal is to get the benefits of PTFE without the drawback of its rigidity.

The Engineering Solution: A Flexible-by-Design Approach

The design of a modern PTFE lip seal is a masterclass in using geometry to alter a material's functional properties.

The Thin Lip Cross-Section

The most critical design element is the thin, cantilevered lip. This slender cross-section is engineered to act as a flexible beam. Even though the material itself is stiff, this geometry allows the lip to bend with very little force. This flexibility enables the seal to maintain contact with the shaft, compensating for dynamic runout and thermal expansion.

The Rigid Metal Case

The PTFE sealing element is almost always housed within a rigid metal casing (typically stainless steel). This case serves two vital functions. First, it provides the structural integrity for the seal to be pressed into a housing bore. Second, it provides a fixed anchor point from which the thin PTFE lip can flex, ensuring the sealing point remains stable.

Accommodating Shaft Imperfections

The flexibility endowed by the thin lip design is what allows the seal to handle real-world conditions. When a shaft has minor misalignment or eccentricity, the lip can move with the shaft's surface, ensuring the contact line is never broken and the seal is maintained.

Understanding the Trade-offs

While this design is highly effective, it's essential to recognize the inherent trade-offs that come with using PTFE.

Limited Elastic Memory

Unlike rubber, PTFE is not truly elastic; it has poor "elastic memory." While the thin lip is flexible, if it is over-stressed or deformed, it will not return to its original shape. This makes proper handling and installation absolutely critical.

Installation Sensitivity

The stiffness of the material, even in a thin profile, makes the seal prone to damage during installation. Nicking, scratching, or folding the lip during assembly is a primary cause of premature seal failure. Specialized installation tools and procedures are often required.

Making the Right Choice for Your Application

Understanding this design allows you to select and apply PTFE seals correctly based on your primary operational goal.

- If your primary focus is high surface speeds or low friction: The thin, low-pressure contact of the PTFE lip design generates significantly less heat and drag than a conventional rubber seal.

- If your primary focus is chemical compatibility or temperature resistance: This design allows you to use the superior material properties of PTFE in a dynamic sealing application where it would otherwise be unsuitable.

- If your primary focus is managing shaft runout in a demanding environment: The seal's engineered flexibility is specifically intended to maintain integrity under imperfect mechanical conditions.

By using geometry to create flexibility, the PTFE lip seal design effectively unlocks the material's superior properties for dynamic applications.

Summary Table:

| Design Feature | Function | Key Benefit |

|---|---|---|

| Thin Lip Cross-Section | Acts as a flexible beam | Allows the stiff PTFE to bend and maintain shaft contact |

| Rigid Metal Case | Provides structural support and an anchor point | Ensures stable installation and controlled lip flexing |

| Cantilevered Lip Profile | Functions like a spring | Compensates for shaft runout, misalignment, and thermal expansion |

Need a PTFE seal that can handle your toughest conditions?

At KINTEK, we specialize in precision-engineered PTFE components, including lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your seals are designed to leverage PTFE's chemical and thermal resistance while accommodating its stiffness for reliable, long-lasting performance—from prototypes to high-volume orders.

Contact us today to discuss your application and get a custom solution!

Visual Guide

Related Products

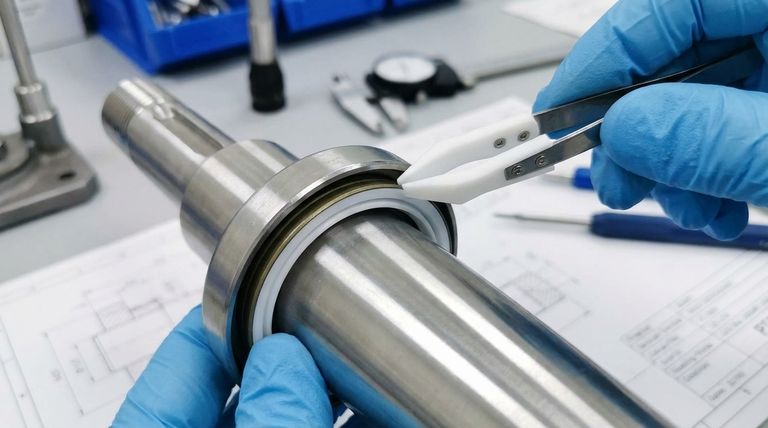

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials