At its core, Polytetrafluoroethylene (PTFE) is considered chemically inert because of its unique molecular structure. The incredibly strong bonds between its carbon and fluorine atoms create a stable, non-reactive material. For bushings, this inertness is a critical advantage, as it ensures they will not corrode, degrade, or contaminate their environment when exposed to aggressive chemicals, acids, or solvents.

The true value of PTFE's chemical inertness lies in its predictability. By effectively creating a molecular shield, it guarantees that a bushing will maintain its structural integrity and functional performance in harsh chemical environments where most other materials would quickly fail.

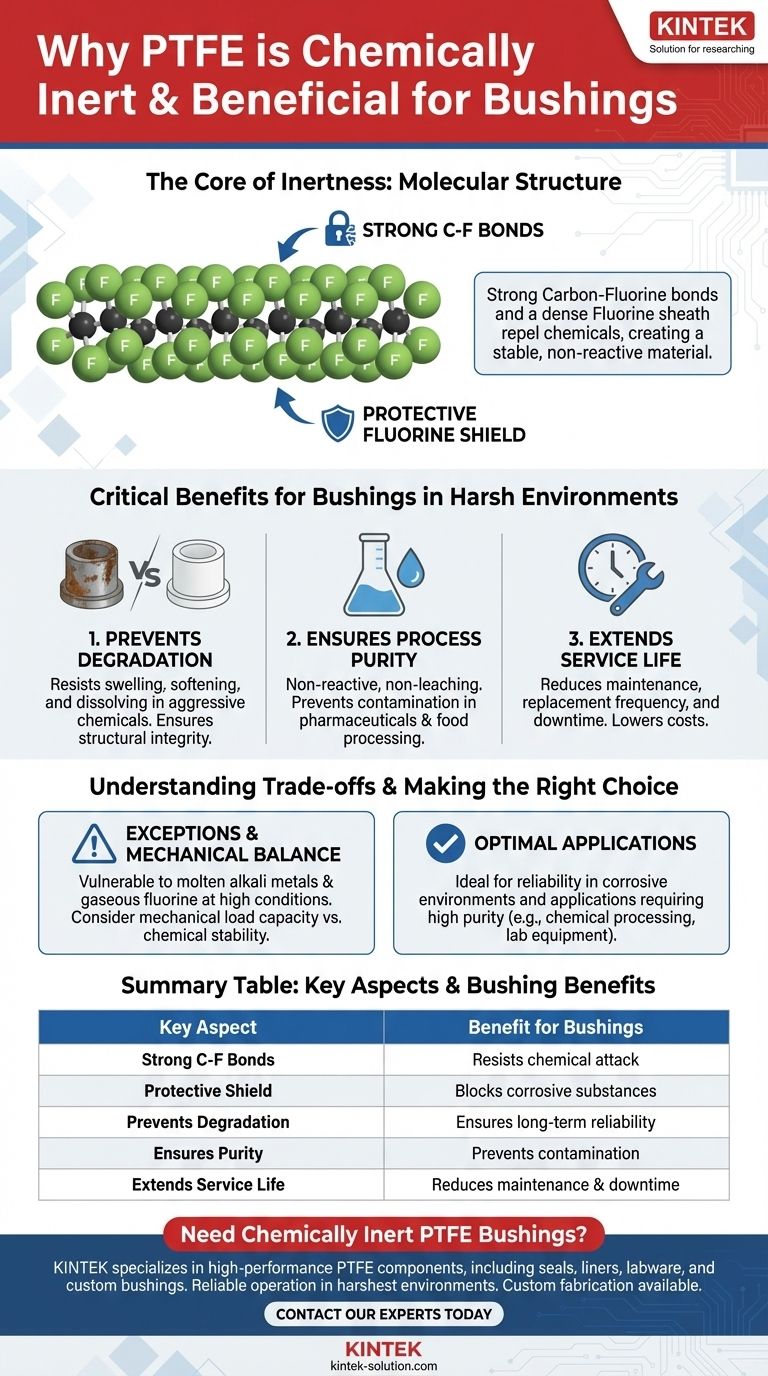

The Molecular Basis of PTFE's Inertness

To understand why PTFE is so non-reactive, we must look at its atomic-level construction. Its properties are not accidental; they are a direct result of fundamental chemistry.

The Power of the Carbon-Fluorine Bond

PTFE is a polymer, a long chain of repeating units. In this case, the backbone is made of carbon atoms, and each carbon is bonded to two fluorine atoms.

The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry. Fluorine is the most electronegative element, meaning it holds its bonding electrons very tightly, creating a short, stable, and difficult-to-break connection.

A Protective Fluorine Shield

The fluorine atoms are larger than the carbon atoms they are attached to. As a result, they form a tight, protective sheath around the vulnerable carbon backbone.

This dense helical shield of negative fluorine atoms physically blocks and electronically repels almost any chemical that would try to attack the carbon chain, rendering the molecule inert.

Why Inertness is Critical for Bushing Performance

A bushing's primary role is to provide a low-friction surface between moving parts. If that surface is compromised, the entire assembly can fail. Chemical inertness is the key to ensuring its reliability in demanding industries.

Preventing Degradation and Failure

In chemical processing, oil and gas, and petrochemical industries, bushings are constantly exposed to corrosive substances.

PTFE's inertness means it will not swell, soften, or dissolve when in contact with these chemicals. This prevents premature wear and catastrophic failure, ensuring the equipment operates safely.

Ensuring Process Purity

In applications like pharmaceuticals, food processing, or laboratory equipment, the bushing material cannot leach any substances into the process fluid.

Because PTFE does not react with its environment, it will not contaminate sensitive products. This purity is often a regulatory requirement and is essential for product quality and safety.

Extending Service Life

The non-reactive nature of PTFE directly translates to a longer operational life for the bushing.

This material resilience reduces the frequency of maintenance and replacement, lowering operational costs and minimizing equipment downtime. It allows for maintenance-free operation in many cases.

Understanding the Trade-offs

While its chemical resistance is nearly absolute, it's important to recognize that PTFE is not without its limitations. True expertise lies in knowing when and where to apply a material.

Exceptions to Inertness

PTFE is practically inert to all common chemicals. However, it can be attacked by a few highly reactive substances under specific conditions.

These exceptions include molten alkali metals (like sodium), gaseous fluorine, and certain complex halogenated compounds at very high temperatures and pressures. For the vast majority of industrial applications, these conditions are not a concern.

Physical vs. Chemical Properties

A material's suitability is a balance of all its properties. While PTFE excels in chemical and thermal resistance, its mechanical properties must be considered.

Compared to metallic bushings, PTFE has a lower load-carrying capacity and can be more susceptible to creep (deformation under sustained load). The design must always account for the specific mechanical stresses of the application.

Making the Right Choice for Your Application

Selecting the right bushing material depends entirely on the operational demands and the primary goal you need to achieve.

- If your primary focus is reliability in corrosive environments: PTFE is the superior choice, as its chemical inertness guarantees longevity and prevents degradation from aggressive substances.

- If your primary focus is preventing product contamination: PTFE's non-reactive and non-leaching properties make it essential for food, pharmaceutical, and laboratory applications.

- If your primary focus is high-load mechanical performance in a neutral environment: You must carefully evaluate if PTFE's strength is sufficient, as a metallic or composite bushing may offer better performance when chemical attack is not a factor.

Ultimately, choosing PTFE is a decision to prioritize chemical stability and purity above all else.

Summary Table:

| Key Aspect | Benefit for Bushings |

|---|---|

| Strong C-F Bonds | Creates a stable, non-reactive material that resists chemical attack. |

| Protective Fluorine Shield | Physically blocks and electronically repels corrosive substances. |

| Prevents Degradation | Bushings will not swell, soften, or dissolve, ensuring long-term reliability. |

| Ensures Purity | Non-leaching properties prevent contamination in sensitive applications like pharmaceuticals and food processing. |

| Extends Service Life | Reduces maintenance frequency and operational downtime in corrosive environments. |

Need chemically inert PTFE bushings that guarantee performance and purity?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components, including seals, liners, labware, and custom bushings. Our expertise ensures your bushings provide reliable, maintenance-free operation in the harshest chemical environments, from semiconductor manufacturing to medical and laboratory applications.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let's discuss your project – contact our experts today to get started!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments