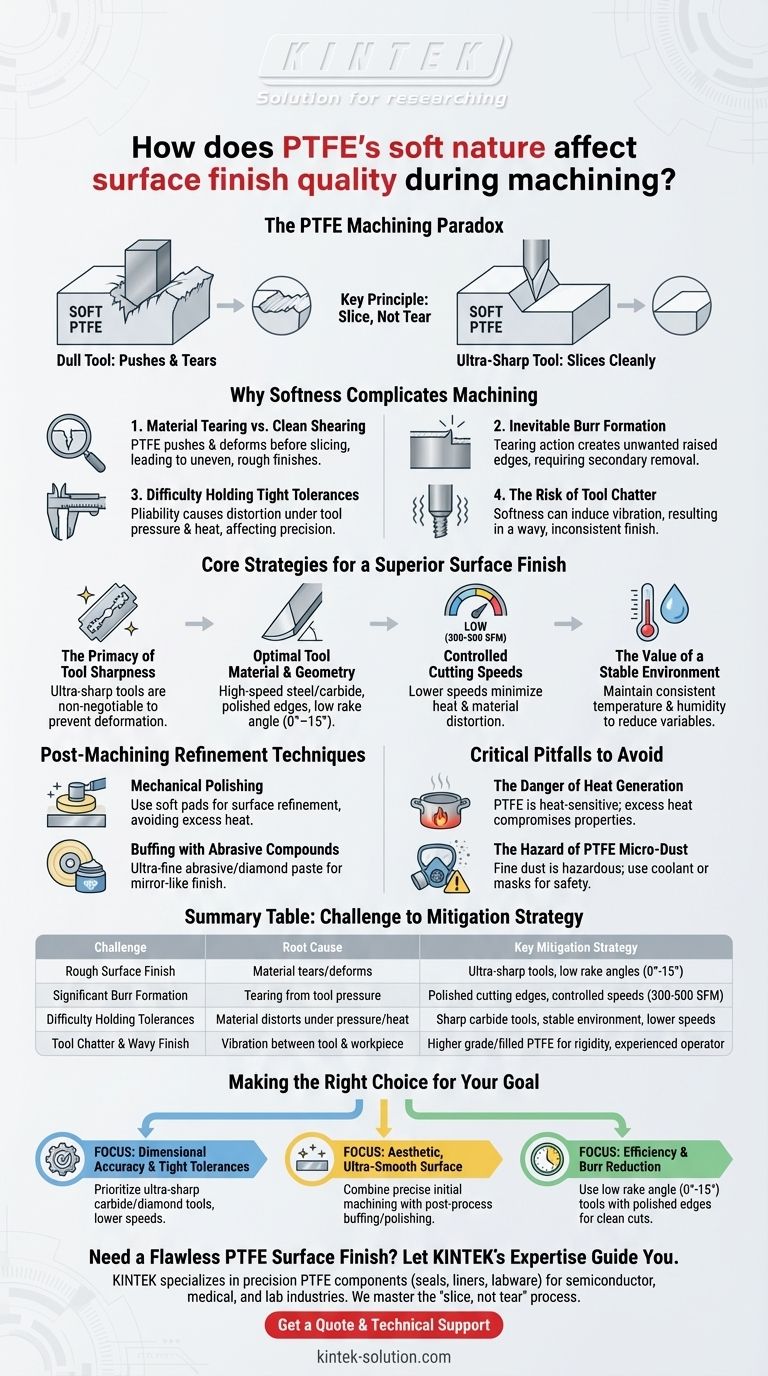

Machining PTFE presents a paradox: its softness makes it easy to cut, yet incredibly difficult to finish well. The material's tendency to deform and tear rather than shear cleanly is the primary cause of rough surfaces, significant burr formation, and challenges in maintaining tight dimensional tolerances.

Achieving a high-quality surface finish on PTFE is less about removing material and more about managing its softness. Success hinges on using ultra-sharp tools with specific geometry to slice the material cleanly, preventing the deformation and tearing that lead to poor results.

Why Softness Complicates PTFE Machining

The very properties that make PTFE valuable—its low friction and pliability—create distinct challenges during the machining process. A successful outcome requires understanding these behaviors.

Material Tearing vs. Clean Shearing

Harder materials shear cleanly when cut. Due to its softness, PTFE tends to be pushed and deformed by a cutting tool before it is actually sliced.

This deformation can lead to tearing on the surface, resulting in an uneven and rough finish rather than a crisp, clean cut.

Inevitable Burr Formation

The tearing action almost always produces burrs, which are small, raised edges of unwanted material. These must be removed in a secondary process, adding time and complexity.

Difficulty Holding Tight Tolerances

Because PTFE is so pliable, it can easily distort under the pressure and heat of the cutting tool. This makes holding precise dimensions and tight tolerances a significant challenge.

The Risk of Tool Chatter

While PTFE's softness makes it seem easy to cut, it can also lead to tool chatter. This vibration between the tool and the workpiece produces a wavy, inconsistent surface finish.

Using a higher grade of PTFE or a filled variant (e.g., glass-filled) can add rigidity and help mitigate this issue.

Core Strategies for a Superior Surface Finish

Overcoming the challenges of PTFE's softness requires a deliberate and precise approach focused on tooling, parameters, and environment.

The Primacy of Tool Sharpness

Ultra-sharp tools are non-negotiable. A dull edge will exacerbate the material's tendency to deform and tear. Sharp tools are essential for slicing the material cleanly.

Optimal Tool Material and Geometry

Tools should be made from high-speed steel or carbide, with polished cutting edges to reduce friction further. Diamond-coated tools are also highly effective.

A low rake angle (0°–15°) is critical. This geometry helps the tool slice cleanly through the material, preventing it from digging in and causing deformation.

Controlled Cutting Speeds

Lower cutting speeds are generally required for PTFE. A typical range is 300–500 surface feet per minute (SFM).

Slower speeds minimize heat generation and material distortion, giving the operator greater control over the final dimensions and finish.

The Value of a Stable Environment

Consistency is key. Maintaining a stable machining environment, including temperature and humidity, helps reduce process variables that can affect the material's behavior.

Experienced operators who can make real-time adjustments are invaluable for achieving the highest quality and efficiency.

Post-Machining Refinement Techniques

For applications requiring an exceptionally smooth surface, machining alone may not be sufficient. Post-processing steps can elevate the finish to a higher standard.

Mechanical Polishing

Using felt or other soft pads for mechanical polishing is an effective way to refine the surface. Care must be taken to avoid generating excess heat during this process.

Buffing with Abrasive Compounds

For the finest finishes, buffing with ultra-fine abrasive compounds or diamond paste can achieve a mirror-like surface, removing any microscopic imperfections left by machining.

Critical Pitfalls to Avoid

While focusing on the finish, it's crucial to be aware of the associated risks to both the part and the operator.

The Danger of Heat Generation

PTFE is highly sensitive to heat. Excessive heat from dull tools, high cutting speeds, or aggressive polishing can compromise the material's properties and dimensional stability.

The Hazard of PTFE Micro-Dust

Machining PTFE produces fine micro-dust. This dust can be hazardous if inhaled. Always use a mask or machine the material under coolant to suppress dust and ensure operator safety.

Making the Right Choice for Your Goal

Your strategy should align with the most critical outcome for your component.

- If your primary focus is dimensional accuracy and tight tolerances: Prioritize ultra-sharp carbide or diamond-coated tools and lower cutting speeds to prevent material distortion.

- If your primary focus is an aesthetic, ultra-smooth surface: Combine precise initial machining with post-processing steps like buffing with diamond paste or careful mechanical polishing.

- If your primary focus is efficiency and burr reduction: Use tools with a low (0°-15°) rake angle and polished cutting edges to ensure the cleanest possible initial cut.

Mastering PTFE machining means respecting its unique properties and adapting your process to slice, not tear, the material.

Summary Table:

| Challenge | Root Cause | Key Mitigation Strategy |

|---|---|---|

| Rough Surface Finish | Material tears and deforms instead of shearing | Ultra-sharp tools with low rake angles (0°-15°) |

| Significant Burr Formation | Tearing action from tool pressure | Polished cutting edges and controlled speeds (300-500 SFM) |

| Difficulty Holding Tolerances | Material distorts under tool pressure and heat | Sharp carbide tools, stable environment, and lower speeds |

| Tool Chatter & Wavy Finish | Vibration between tool and soft workpiece | Higher grade/filled PTFE for rigidity, experienced operator |

Need a Flawless PTFE Surface Finish? Let KINTEK's Expertise Guide You

Achieving a high-quality surface finish on soft PTFE components requires precise tooling, controlled parameters, and deep material knowledge. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and laboratory industries.

We master the 'slice, not tear' process for PTFE, ensuring your parts meet the strictest dimensional and aesthetic requirements. From prototypes to high-volume orders, our custom fabrication prioritizes precision and quality.

Contact us today to discuss your project and experience the KINTEK difference. Get a Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech