Choose PTFE bellows for systems demanding extreme chemical inertness, a wide operating temperature range, and absolute purity. They excel in applications where materials like metal or rubber would corrode, degrade, or contaminate the process media, especially when flexibility is also a key requirement.

The decision to use PTFE bellows is not about choosing the strongest material, but the most resilient. It is the definitive choice for systems where chemical compatibility and non-contamination are more critical than handling high pressure or abrasive particles.

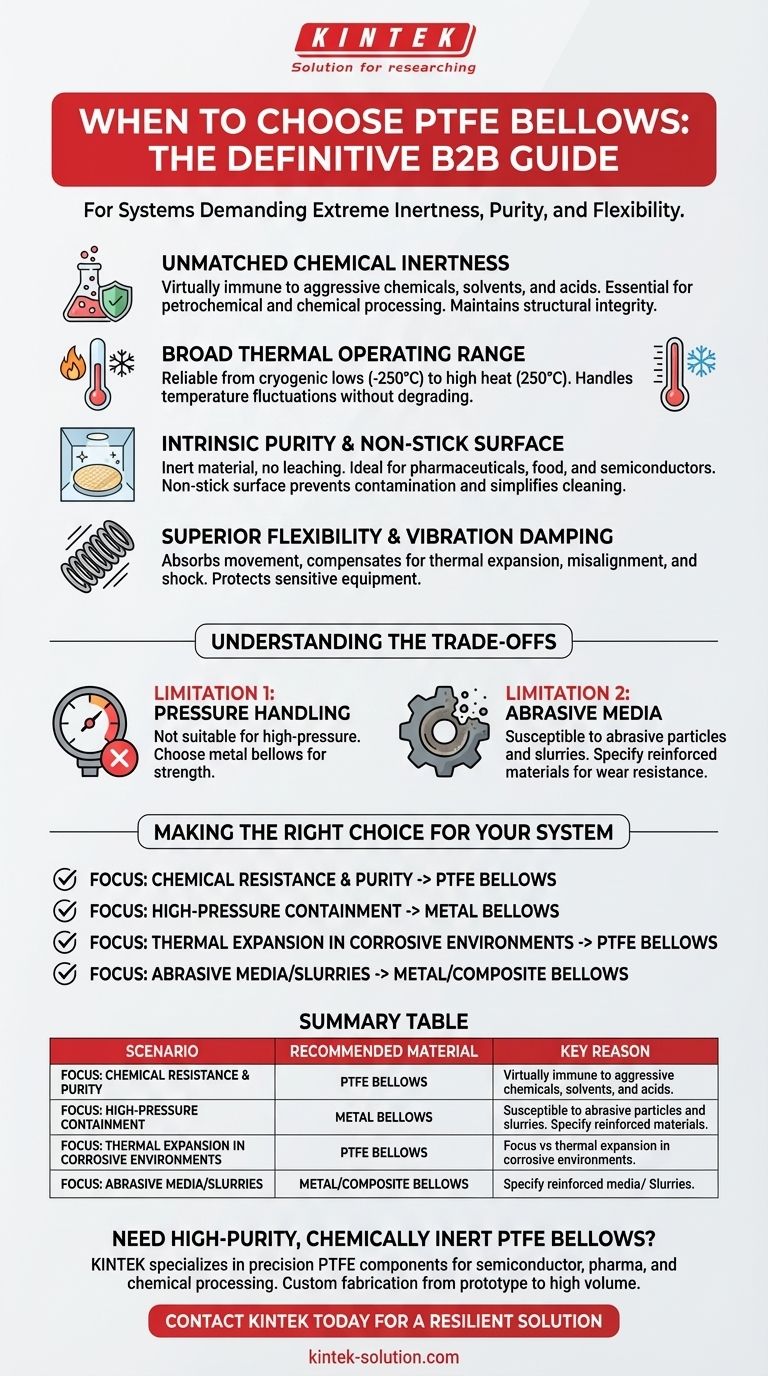

The Defining Characteristics of PTFE Bellows

Understanding the unique properties of Polytetrafluoroethylene (PTFE) is key to knowing when to deploy it. Its value comes from a combination of characteristics that few other materials can offer simultaneously.

Unmatched Chemical Inertness

PTFE is virtually immune to attack from aggressive chemicals, solvents, and acids. This makes it an essential component in petrochemical pipelines and chemical processing plants.

Where other materials would fail, PTFE maintains its dimensional stability and structural integrity, ensuring system reliability.

Broad Thermal Operating Range

PTFE performs reliably across an exceptionally wide temperature spectrum, from cryogenic lows up to approximately 480°F (250°C).

This thermal stability allows it to handle processes involving extreme temperature fluctuations without becoming brittle or degrading.

Intrinsic Purity and Non-Stick Surface

For industries like pharmaceuticals, food production, and semiconductor manufacturing, preventing contamination is non-negotiable. PTFE is an inert material that will not leach into or react with the process media.

Its well-known non-stick properties also facilitate easier cleaning and prevent material buildup within the system.

Superior Flexibility and Vibration Damping

Bellows are often used to absorb movement, and PTFE provides excellent flexibility. It effectively compensates for thermal expansion, misalignment, and mechanical shock.

This capacity for shock absorption protects sensitive equipment and ensures the longevity of the entire pipeline or system.

Understanding the Trade-offs: When PTFE is Not the Answer

No material is perfect for every scenario. Being objective about PTFE's limitations is critical for proper system design and avoiding premature failure. Its unique strengths are balanced by specific weaknesses.

Limitation 1: Pressure Handling

PTFE bellows are not suitable for high-pressure applications. Their inherent flexibility and material properties mean they cannot contain pressures that are easily handled by metal bellows.

In systems where high internal pressure is a primary design constraint, a robust material like stainless steel or another metal alloy is the more appropriate choice.

Limitation 2: Abrasive Media

The material's surface, while durable against chemicals, is susceptible to damage from abrasive particles. Slurries or media containing hard particulates can wear down and erode PTFE over time.

For applications involving abrasive wear, reinforced composite or hardened metal bellows offer far greater durability.

Making the Right Choice for Your System

Your final decision should be guided by the primary challenge your system must overcome.

- If your primary focus is chemical resistance and purity: PTFE is almost certainly the correct choice, especially in food, pharmaceutical, or aggressive chemical applications.

- If your primary focus is high-pressure containment: You must look to metal bellows, as PTFE lacks the required mechanical strength.

- If your primary focus is managing thermal expansion in a corrosive environment: PTFE's unique combination of flexibility and chemical inertness makes it the ideal solution.

- If your primary focus is handling abrasive slurries: Avoid PTFE entirely and specify a material engineered for high wear resistance, such as metal or a specialized composite.

Choosing the right bellows is a strategic decision based on environmental resilience versus pure mechanical strength.

Summary Table:

| Scenario | Recommended Material | Key Reason |

|---|---|---|

| Chemical Resistance & Purity | PTFE Bellows | Unmatched inertness, prevents contamination |

| High-Pressure Containment | Metal Bellows (e.g., Stainless Steel) | Superior mechanical strength |

| Abrasive Media/Slurries | Metal or Specialized Composite Bellows | Greater resistance to wear and erosion |

| Thermal Expansion in Corrosive Environments | PTFE Bellows | Combines flexibility with chemical inertness |

Need High-Purity, Chemically Inert PTFE Bellows?

KINTEK specializes in manufacturing precision PTFE components, including custom bellows, for industries where contamination is not an option. Whether you're in semiconductor manufacturing, pharmaceuticals, or chemical processing, our expertise ensures your systems achieve maximum reliability and purity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific operational challenges.

Contact KINTEK today to discuss your application requirements and receive a solution designed for resilience.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What advantages does PTFE packing provide? Superior Chemical Resistance, Low Friction & Thermal Stability

- What role does chemical stability play in the performance of Teflon gland fillers? Ensure Long-Term Reliability in Harsh Environments

- Are PTFE butterfly valves suitable for high-pressure applications? Balancing Chemical Resistance & Pressure Limits

- What makes PTFE butterfly valves special compared to other types? Unmatched Chemical & Thermal Performance

- What spring options are available for PTFE seals? A Guide to Cantilever, Canted Coil, and Helical Springs

- What industries use PTFE V-Rings? Critical Sealing Solutions for Demanding Applications

- What are the benefits of using PTFE reducing flanges? Achieve Superior Flow & Corrosion Resistance

- How does PTFE compare to other elastomers in temperature resilience? Unmatched Performance from -200°C to 260°C