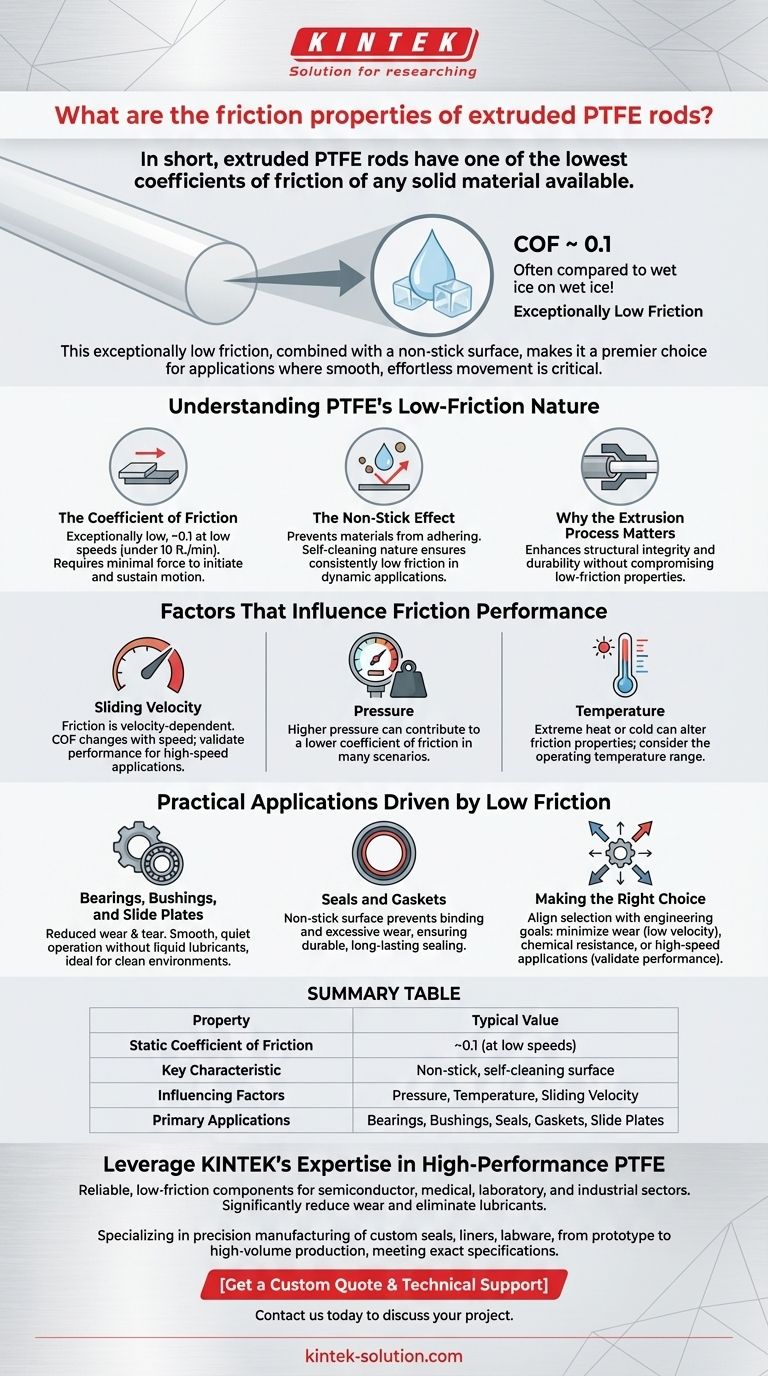

In short, extruded PTFE rods have one of the lowest coefficients of friction of any solid material available. With a static coefficient of friction around 0.1, its performance is often compared to wet ice on wet ice. This exceptionally low friction, combined with a non-stick surface, makes it a premier choice for applications where smooth, effortless movement is critical.

The core value of extruded PTFE is its inherent and extremely low friction. However, you must understand that this is not a static property; its performance is influenced by operational variables like pressure, temperature, and sliding velocity.

Understanding PTFE's Low-Friction Nature

Polytetrafluoroethylene (PTFE) is engineered for minimal resistance. The specialized extrusion and sintering process used for rods enhances its structural integrity and durability while preserving these fundamental low-friction characteristics.

The Coefficient of Friction

The coefficient of friction for PTFE is exceptionally low, typically cited as 0.1 for movement at low speeds (under 10 ft./min). This value quantifies the minimal force required to move one surface over another.

This property means that components made from extruded PTFE rods require significantly less energy to initiate and sustain motion, reducing both operational costs and mechanical wear.

The "Non-Stick" Effect

Beyond its low friction coefficient, PTFE is famously non-stick. This characteristic prevents other materials from adhering to its surface.

In dynamic applications, this self-cleaning nature ensures that friction remains consistently low, as contaminants and residues cannot easily build up on the sliding surface.

Why the Extrusion Process Matters

The extrusion process used to create rods enhances the material's durability and chemical resistance. This strengthening of the molecular structure ensures that the PTFE can withstand mechanical stress without compromising its inherent low-friction properties.

Factors That Influence Friction Performance

The stated coefficient of friction is a baseline, not an absolute constant. To properly engineer a solution with PTFE, you must consider the conditions under which it will operate.

The Impact of Sliding Velocity

The friction properties of PTFE are velocity-dependent. The often-quoted 0.1 value is most accurate at very low sliding speeds.

As velocity increases, the coefficient of friction can change. Therefore, it is critical to test or validate performance for any high-speed application.

The Role of Pressure

The load or pressure applied to the PTFE surface also influences its frictional behavior. In many scenarios, higher pressure can contribute to a lower coefficient of friction.

The Effect of Temperature

Temperature is another key variable. While PTFE has a wide operating temperature range, extreme heat or cold can alter its physical properties, including friction.

Practical Applications Driven by Low Friction

The unique combination of properties in extruded PTFE rods makes them ideal for specific mechanical roles where minimizing resistance is the primary goal.

Bearings, Bushings, and Slide Plates

In these applications, PTFE's low friction directly translates to reduced wear and tear on moving parts. It allows for smooth, quiet operation without the need for liquid lubricants, which is essential in clean or chemically sensitive environments.

Seals and Gaskets

The non-stick, low-friction surface allows PTFE seals to function effectively against moving components without binding or causing excessive wear. This ensures a durable, long-lasting seal that maintains its integrity over time.

Making the Right Choice for Your Goal

To leverage the properties of extruded PTFE effectively, align your selection with your primary engineering objective.

- If your primary focus is minimizing wear in slow-moving parts: Extruded PTFE is an ideal choice due to its exceptionally low static friction and excellent performance at low velocities.

- If your primary focus is performance in a chemically harsh environment: The material's virtual immunity to chemical attack, combined with its low friction, makes it a uniquely reliable solution.

- If your primary focus is a high-speed application: You must validate performance, as the coefficient of friction is not constant and will change with increased velocity and temperature.

Ultimately, understanding these properties empowers you to design systems that are more efficient, durable, and reliable.

Summary Table:

| Property | Typical Value for Extruded PTFE Rods |

|---|---|

| Static Coefficient of Friction | ~0.1 (at low speeds) |

| Key Characteristic | Non-stick, self-cleaning surface |

| Influencing Factors | Pressure, Temperature, Sliding Velocity |

| Primary Applications | Bearings, Bushings, Seals, Gaskets, Slide Plates |

Leverage KINTEK's Expertise in High-Performance PTFE

Do you need a reliable, low-friction component for a demanding application in the semiconductor, medical, laboratory, or industrial sectors? The exceptional properties of extruded PTFE rods—like a coefficient of friction as low as 0.1—can significantly reduce wear, eliminate the need for lubricants, and ensure long-lasting performance in harsh environments.

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom seals, liners, labware, and more. We work with you from prototype to high-volume production to ensure your parts meet exact specifications for friction, chemical resistance, and durability.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your product's efficiency and reliability.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance