In short, Polytetrafluoroethylene (PTFE) enhances baseball equipment by fundamentally reducing friction and increasing durability. This is applied to bats to enable a faster, smoother swing and to the internal components of pitching machines to ensure consistent, accurate pitches with less mechanical wear.

The core value of PTFE in baseball is not just surface protection; it's the application of material science to gain a measurable advantage. By minimizing friction, PTFE translates into tangible improvements in both player performance and equipment reliability.

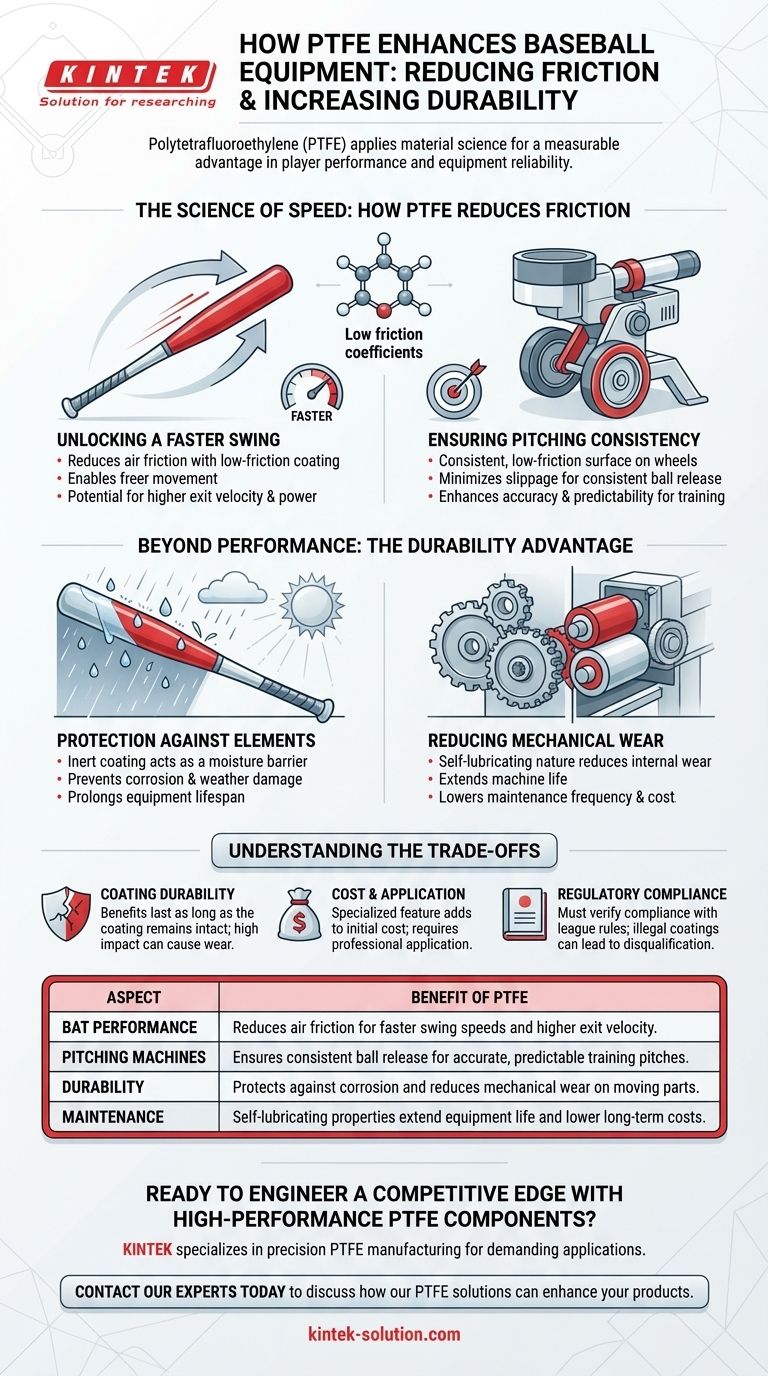

The Science of Speed: How PTFE Reduces Friction

The primary benefit of PTFE stems from its unique molecular structure, which gives it one of the lowest coefficients of friction of any known solid. This "slipperiness" is the key to its performance enhancement.

Unlocking a Faster Swing

When applied as a coating to a baseball bat, PTFE reduces the friction between the bat's surface and the air. This allows the bat to move more freely, potentially increasing swing speed. A faster swing can translate directly to higher exit velocity and greater power.

Ensuring Pitching Consistency

In automated pitching machines, wheels grip and propel the baseball. PTFE-coated wheels or components provide a consistent, low-friction surface that releases the ball with minimal variance. This reduces slippage and ensures that each pitch is delivered with greater accuracy and predictability, which is critical for effective training.

Beyond Performance: The Durability Advantage

While speed and consistency are performance benefits, PTFE also plays a crucial role in protecting equipment and reducing the need for maintenance. Its inherent properties make it exceptionally resilient.

Protection Against the Elements

The same chemical inertness that makes PTFE useful in industrial settings protects baseball equipment. A PTFE coating on a metal or composite bat acts as a barrier against moisture, preventing weather-related damage and corrosion that can degrade performance and shorten the bat's lifespan.

Reducing Mechanical Wear and Tear

Moving parts are a primary point of failure in any machine. In pitching machines, the self-lubricating nature of PTFE components means they experience significantly less wear over time. This extends the life of the machine and reduces the frequency of costly repairs and maintenance.

Understanding the Trade-offs

While the benefits are clear, it is important to consider the practical limitations of using PTFE coatings on sports equipment.

Durability of the Coating

A key limitation is that the benefits only last as long as the coating is intact. On a high-impact surface like a baseball bat, a PTFE coating can chip or wear away over time, diminishing its friction-reducing effects.

Cost and Application

PTFE coatings are a specialized feature that can add to the initial cost of the equipment. Retrofitting equipment with a proper coating is not a simple DIY project and requires professional application to ensure it adheres correctly and performs as expected.

Regulatory Compliance

Crucially, any coating or modification applied to a baseball bat must be compliant with the rules of the specific league or governing body. An illegal coating can result in disqualification, so always verify the regulations before using or modifying equipment.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in equipment featuring PTFE depends on your specific priorities.

- If your primary focus is player performance: The friction-reducing properties offer a direct, science-backed path to faster swings and more consistent training.

- If your primary focus is equipment longevity: PTFE’s protective and self-lubricating nature will extend the life of your bats and pitching machines, reducing long-term costs.

- If you are considering modifying equipment: Always prioritize verifying that any after-market coating is fully compliant with your league's specific rules and regulations.

By understanding the distinct advantages of this material, you can make an informed decision that aligns with your performance and maintenance goals.

Summary Table:

| Aspect | Benefit of PTFE |

|---|---|

| Bat Performance | Reduces air friction for faster swing speeds and higher exit velocity. |

| Pitching Machines | Ensures consistent ball release for accurate, predictable training pitches. |

| Durability | Protects against corrosion and reduces mechanical wear on moving parts. |

| Maintenance | Self-lubricating properties extend equipment life and lower long-term costs. |

Ready to Engineer a Competitive Edge with High-Performance PTFE Components?

At KINTEK, we specialize in precision PTFE manufacturing for demanding applications. Whether you're developing the next generation of baseball equipment or require durable, low-friction components for the semiconductor, medical, or industrial sectors, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the performance and reliability you need.

Contact our experts today to discuss how our PTFE solutions can enhance your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes PTFE expansion bellows suitable for aerospace applications? Unmatched Reliability in Extreme Environments

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability

- How do PTFE expansion bellows enhance reliability in pharmaceutical manufacturing? Ensure Purity and Uptime

- Why choose PTFE V-Ring seals? Unmatched Reliability for Extreme Conditions

- How are PTFE diaphragms manufactured? Achieve Optimal Performance for Your Application

- What material are PTFE ring gaskets made from? Unlock Superior Chemical & Thermal Sealing

- What maintenance practices are recommended for PTFE gaskets? Ensure Long-Term Reliability and Prevent Leaks

- Why should negative pressure be avoided in PTFE lined butterfly valves? Prevent Catastrophic Liner Collapse